MAINTENANCE

Spark Plug

Spark Plug Inspection and Replacement

2.Remove the spark plug cap (B).

3.Clean any dirt from around the base of the spark plug.

4.Using a spark plug wrench, remove the spark plug.

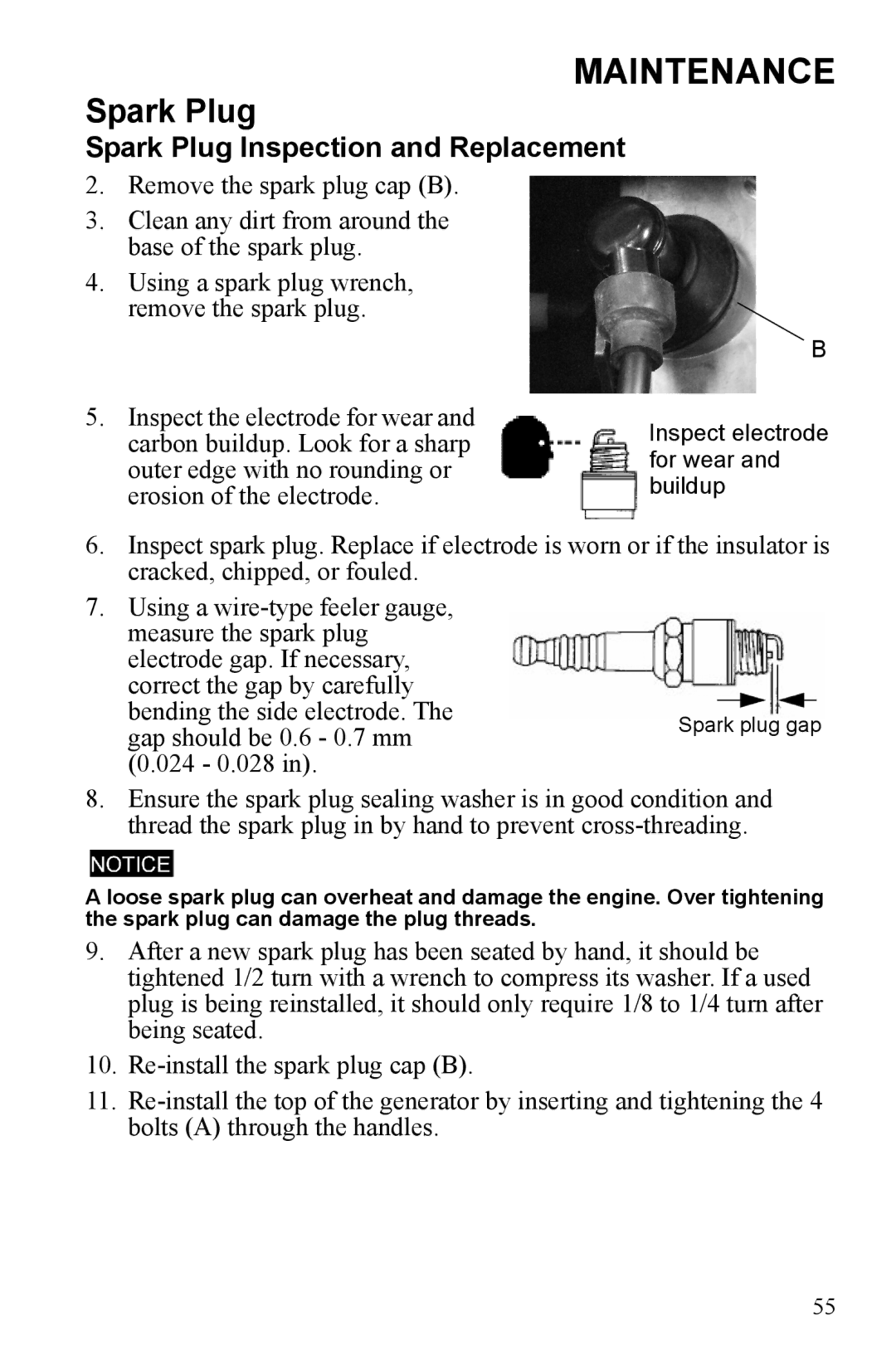

5.Inspect the electrode for wear and carbon buildup. Look for a sharp outer edge with no rounding or erosion of the electrode.

B

Inspect electrode for wear and buildup

6.Inspect spark plug. Replace if electrode is worn or if the insulator is cracked, chipped, or fouled.

7.Using a

bending the side electrode. The | Spark plug gap | |

gap should be 0.6 - 0.7 mm | ||

| ||

(0.024 - 0.028 in). |

|

8.Ensure the spark plug sealing washer is in good condition and thread the spark plug in by hand to prevent

A loose spark plug can overheat and damage the engine. Over tightening the spark plug can damage the plug threads.

9.After a new spark plug has been seated by hand, it should be tightened 1/2 turn with a wrench to compress its washer. If a used plug is being reinstalled, it should only require 1/8 to 1/4 turn after being seated.

10.

11.

55