Vent Pipe Material

Combustion Air Inlet Piping; The following plastic

materials may be used for combustion air inlet piping. IMPORTANT: Follow all local codes or, in the absence of local codes, CSA B149.1, Natural Gas and Propane Installation Code - current edition to properly install air inlet piping.

•Schedule 40 PVC

•Schedule 40 or 80 CPVC

•DWV Pipe and Foam Core Piping is acceptable as intake pipe only.

Exhaust Piping; Exhaust PVC or CPVC plastic piping shall be certified and marked as complying to Standard for Type BH Gas Venting System

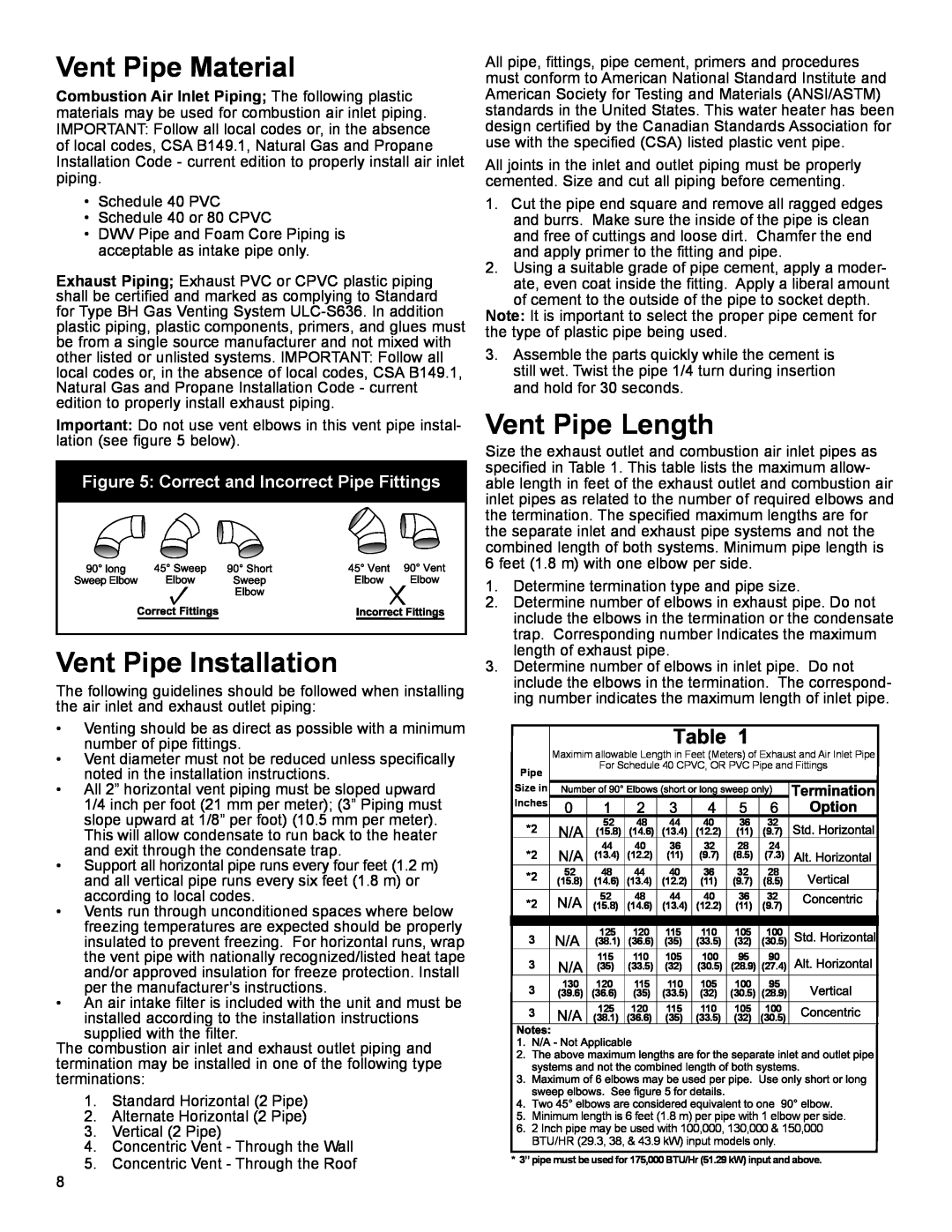

Important: Do not use vent elbows in this vent pipe instal- lation (see figure 5 below).

Figure 5: Correct and Incorrect Pipe Fittings

Vent Pipe Installation

The following guidelines should be followed when installing the air inlet and exhaust outlet piping:

•Venting should be as direct as possible with a minimum number of pipe fittings.

•Vent diameter must not be reduced unless specifically noted in the installation instructions.

•All 2” horizontal vent piping must be sloped upward 1/4 inch per foot (21 mm per meter); (3” Piping must slope upward at 1/8” per foot) (10.5 mm per meter). This will allow condensate to run back to the heater and exit through the condensate trap.

•Support all horizontal pipe runs every four feet (1.2 m) and all vertical pipe runs every six feet (1.8 m) or according to local codes.

•Vents run through unconditioned spaces where below freezing temperatures are expected should be properly insulated to prevent freezing. For horizontal runs, wrap the vent pipe with nationally recognized/listed heat tape and/or approved insulation for freeze protection. Install per the manufacturer’s instructions.

•An air intake filter is included with the unit and must be

installed according to the installation instructions supplied with the filter.

The combustion air inlet and exhaust outlet piping and termination may be installed in one of the following type terminations:

1.Standard Horizontal (2 Pipe)

2.Alternate Horizontal (2 Pipe)

3.Vertical (2 Pipe)

4.Concentric Vent - Through the Wall

5.Concentric Vent - Through the Roof

All pipe, fittings, pipe cement, primers and procedures must conform to American National Standard Institute and American Society for Testing and Materials (ANSI/ASTM) standards in the United States. This water heater has been design certified by the Canadian Standards Association for use with the specified (CSA) listed plastic vent pipe.

All joints in the inlet and outlet piping must be properly cemented. Size and cut all piping before cementing.

1.Cut the pipe end square and remove all ragged edges and burrs. Make sure the inside of the pipe is clean and free of cuttings and loose dirt. Chamfer the end and apply primer to the fitting and pipe.

2.Using a suitable grade of pipe cement, apply a moder- ate, even coat inside the fitting. Apply a liberal amount of cement to the outside of the pipe to socket depth.

Note: It is important to select the proper pipe cement for the type of plastic pipe being used.

3.Assemble the parts quickly while the cement is still wet. Twist the pipe 1/4 turn during insertion and hold for 30 seconds.

Vent Pipe Length

Size the exhaust outlet and combustion air inlet pipes as specified in Table 1. This table lists the maximum allow- able length in feet of the exhaust outlet and combustion air inlet pipes as related to the number of required elbows and the termination. The specified maximum lengths are for the separate inlet and exhaust pipe systems and not the combined length of both systems. Minimum pipe length is 6 feet (1.8 m) with one elbow per side.

1.Determine termination type and pipe size.

2.Determine number of elbows in exhaust pipe. Do not include the elbows in the termination or the condensate trap. Corresponding number Indicates the maximum length of exhaust pipe.

3.Determine number of elbows in inlet pipe. Do not include the elbows in the termination. The correspond- ing number indicates the maximum length of inlet pipe.

| Maximim allowable Length in Feet (Meters) of Exhaust and Air Inlet Pipe | ||||||

Pipe |

| For Schedule 40 CPVC, OR PVC Pipe and Fittings | |||||

|

|

|

|

|

|

| |

Size in |

|

|

|

|

|

|

|

Inches |

|

|

|

|

|

|

|

*2 |

| 52 | 48 | 44 | 40 | 36 | 32 |

| (15.8) | (14.6) | (13.4) | (12.2) | (11) | (9.7) | |

*2 |

| 44 | 40 | 36 | 32 | 28 | 24 |

| (13.4) | (12.2) | (11) | (9.7) | (8.5) | (7.3) | |

*2 | 52 | 48 | 44 | 40 | 36 | 32 | 28 |

(15.8) | (14.6) | (13.4) | (12.2) | (11) | (9.7) | (8.5) | |

*2 |

| 52 | 48 | 44 | 40 | 36 | 32 |

| (15.8) | (14.6) | (13.4) | (12.2) | (11) | (9.7) | |

3 |

| 125 | 120 | 115 | 110 | 105 | 100 |

| (38.1) | (36.6) | (35) | (33.5) | (32) | (30.5) | |

3 |

| 115 | 110 | 105 | 100 | 95 | 90 |

| (35) | (33.5) | (32) | (30.5) | (28.9) | (27.4) | |

3 | 130 | 120 | 115 | 110 | 105 | 100 | 95 |

(39.6) | (36.6) | (35) | (33.5) | (32) | (30.5) | (28.9) | |

3 |

| 125 | 120 | 115 | 110 | 105 | 100 |

|

| (38.1) | (36.6) | (35) | (33.5) | (32) | (30.5) |

Minimum length is 6 feet (1.8 m) per pipe with 1 elbow per side. 2 Inch pipe may be used with 100,000, 130,000 & 150,000 BTU/HR (29.3, 38, & 43.9 kW) input models only.

* 3” pipe must be used for 175,000 BTU/Hr (51.29 kW) input and above.

8