REMOVING "HEELING" IN SAW CUT

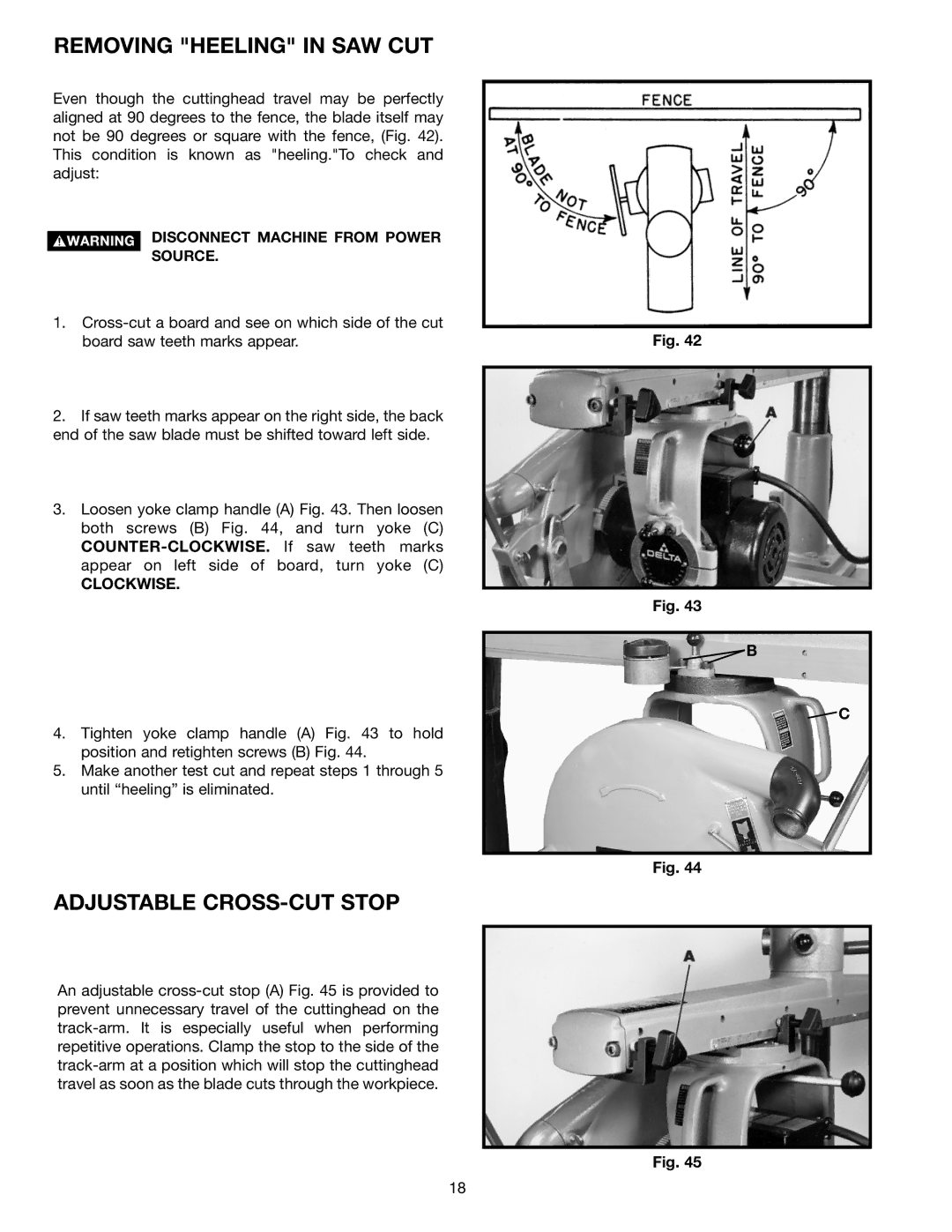

Even though the cuttinghead travel may be perfectly aligned at 90 degrees to the fence, the blade itself may not be 90 degrees or square with the fence, (Fig. 42). This condition is known as "heeling."To check and adjust:

DISCONNECT MACHINE FROM POWER

SOURCE.

1.

2.If saw teeth marks appear on the right side, the back end of the saw blade must be shifted toward left side.

3.Loosen yoke clamp handle (A) Fig. 43. Then loosen both screws (B) Fig. 44, and turn yoke (C)

CLOCKWISE.

4.Tighten yoke clamp handle (A) Fig. 43 to hold position and retighten screws (B) Fig. 44.

5.Make another test cut and repeat steps 1 through 5 until “heeling” is eliminated.

ADJUSTABLE CROSS-CUT STOP

An adjustable

Fig. 42

Fig. 43

![]() B

B

![]() C

C

Fig. 44

Fig. 45

18