ADJUSTING TENSION ON CUTTINGHEAD RETURN ASSEMBLY

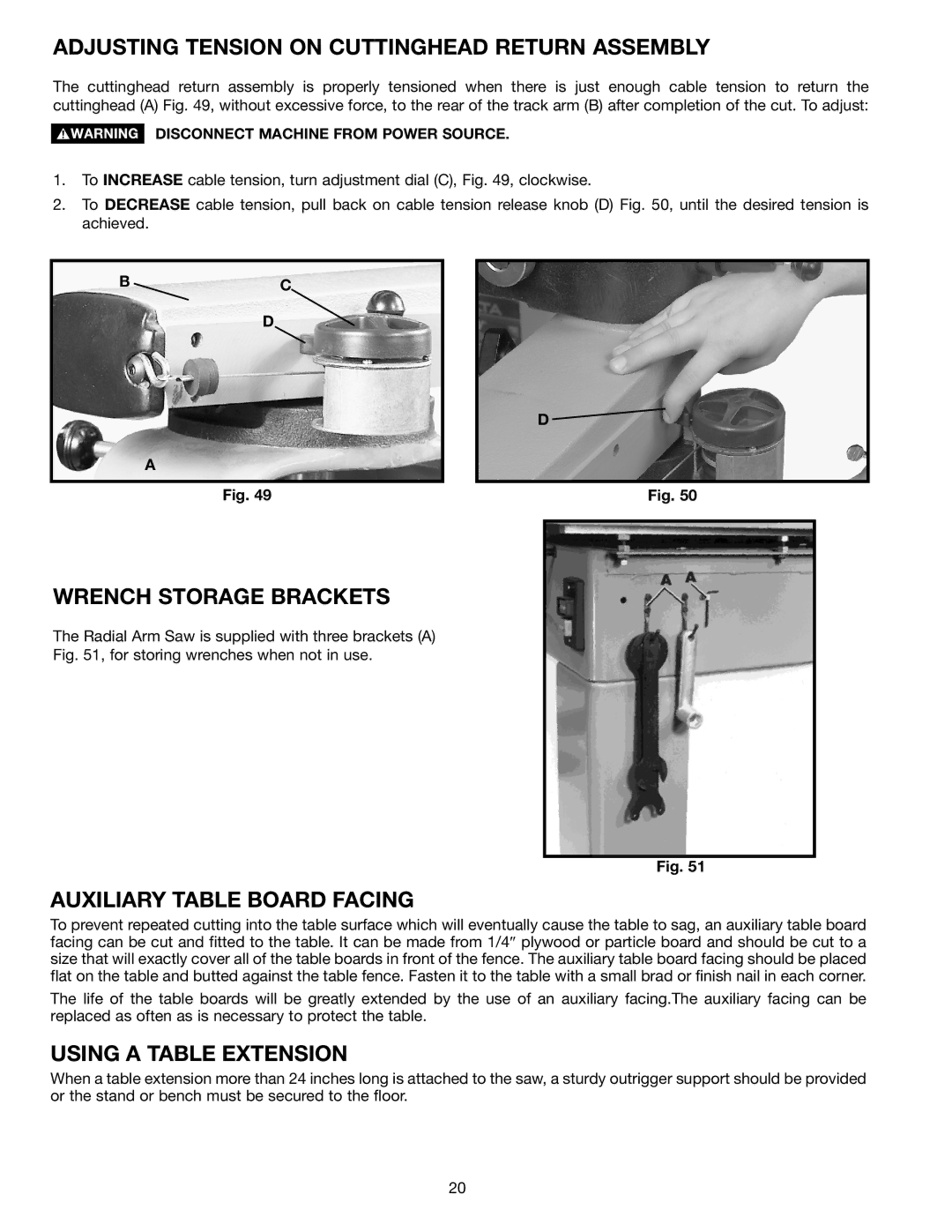

The cuttinghead return assembly is properly tensioned when there is just enough cable tension to return the cuttinghead (A) Fig. 49, without excessive force, to the rear of the track arm (B) after completion of the cut. To adjust:

DISCONNECT MACHINE FROM POWER SOURCE.

1.To INCREASE cable tension, turn adjustment dial (C), Fig. 49, clockwise.

2.To DECREASE cable tension, pull back on cable tension release knob (D) Fig. 50, until the desired tension is achieved.

BC

D

A

Fig. 49

D

Fig. 50

WRENCH STORAGE BRACKETS

The Radial Arm Saw is supplied with three brackets (A)

Fig. 51, for storing wrenches when not in use.

Fig. 51

AUXILIARY TABLE BOARD FACING

To prevent repeated cutting into the table surface which will eventually cause the table to sag, an auxiliary table board facing can be cut and fitted to the table. It can be made from 1/4″ plywood or particle board and should be cut to a size that will exactly cover all of the table boards in front of the fence. The auxiliary table board facing should be placed flat on the table and butted against the table fence. Fasten it to the table with a small brad or finish nail in each corner.

The life of the table boards will be greatly extended by the use of an auxiliary facing.The auxiliary facing can be replaced as often as is necessary to protect the table.

USING A TABLE EXTENSION

When a table extension more than 24 inches long is attached to the saw, a sturdy outrigger support should be provided or the stand or bench must be secured to the floor.

20