Cutterhead Removal

The entire cutterhead assembly may be removed for cleaning or for bearing and blade replacement. Some woodworkers keep a spare cutterhead with replacement blades should the original cutterhead have to be repaired.

Blades in the cutterhead are sharp! Use extreme caution when handling the removal of the cutterhead.

Failure to comply may cause serious injury!

To remove the cutterhead (including bearings, studs, and housing) from the base casting:

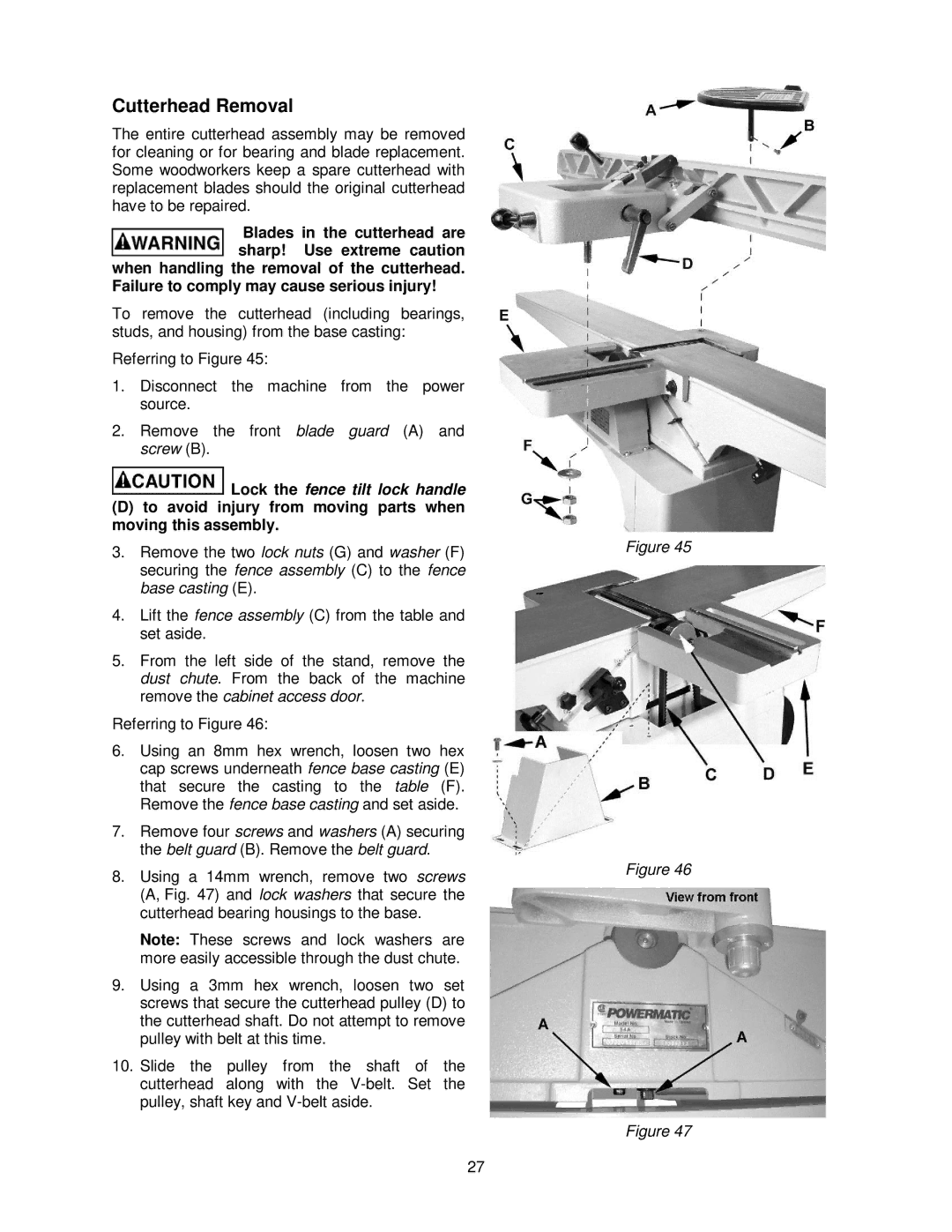

Referring to Figure 45:

1.Disconnect the machine from the power source.

2.Remove the front blade guard (A) and screw (B).

Lock the fence tilt lock handle

Lock the fence tilt lock handle

(D)to avoid injury from moving parts when moving this assembly.

3.Remove the two lock nuts (G) and washer (F) securing the fence assembly (C) to the fence base casting (E).

4.Lift the fence assembly (C) from the table and set aside.

5.From the left side of the stand, remove the dust chute. From the back of the machine remove the cabinet access door.

Referring to Figure 46:

6.Using an 8mm hex wrench, loosen two hex cap screws underneath fence base casting (E) that secure the casting to the table (F). Remove the fence base casting and set aside.

7.Remove four screws and washers (A) securing the belt guard (B). Remove the belt guard.

8.Using a 14mm wrench, remove two screws (A, Fig. 47) and lock washers that secure the cutterhead bearing housings to the base.

Note: These screws and lock washers are more easily accessible through the dust chute.

9.Using a 3mm hex wrench, loosen two set screws that secure the cutterhead pulley (D) to the cutterhead shaft. Do not attempt to remove pulley with belt at this time.

10.Slide the pulley from the shaft of the cutterhead along with the

Figure 45

Figure 46

Figure 47

27