Figure 42

Rabbet Cuts (Straight Knife only)

IMPORTANT: Rabbeting can be done with the straight knife cutterhead only; it is not applicable with the helical cutterhead model.

A rabbet is a groove cut along the edge of a board (Figure 43). It is usually made to accept another board to form a strong, simple joint.

Note: The maximum rabbet depth is 1/2".

1.Unplug the jointer and remove the cutterhead guard.

2.Loosen the fence and slide it to the rabbeting edge. Set the fence to the desired width of the rabbet and lock down.

3.Inspect stock for soundness and grain direction.

4.Place stock on the infeed table and rabbet table with the edge to be rabbeted firmly against the fence.

5.Slowly and evenly feed stock through the cutterhead.

6.Lower the infeed table 1/16" at a time and make successive cuts until the desired depth of rabbet is obtained.

7.

Figure 43

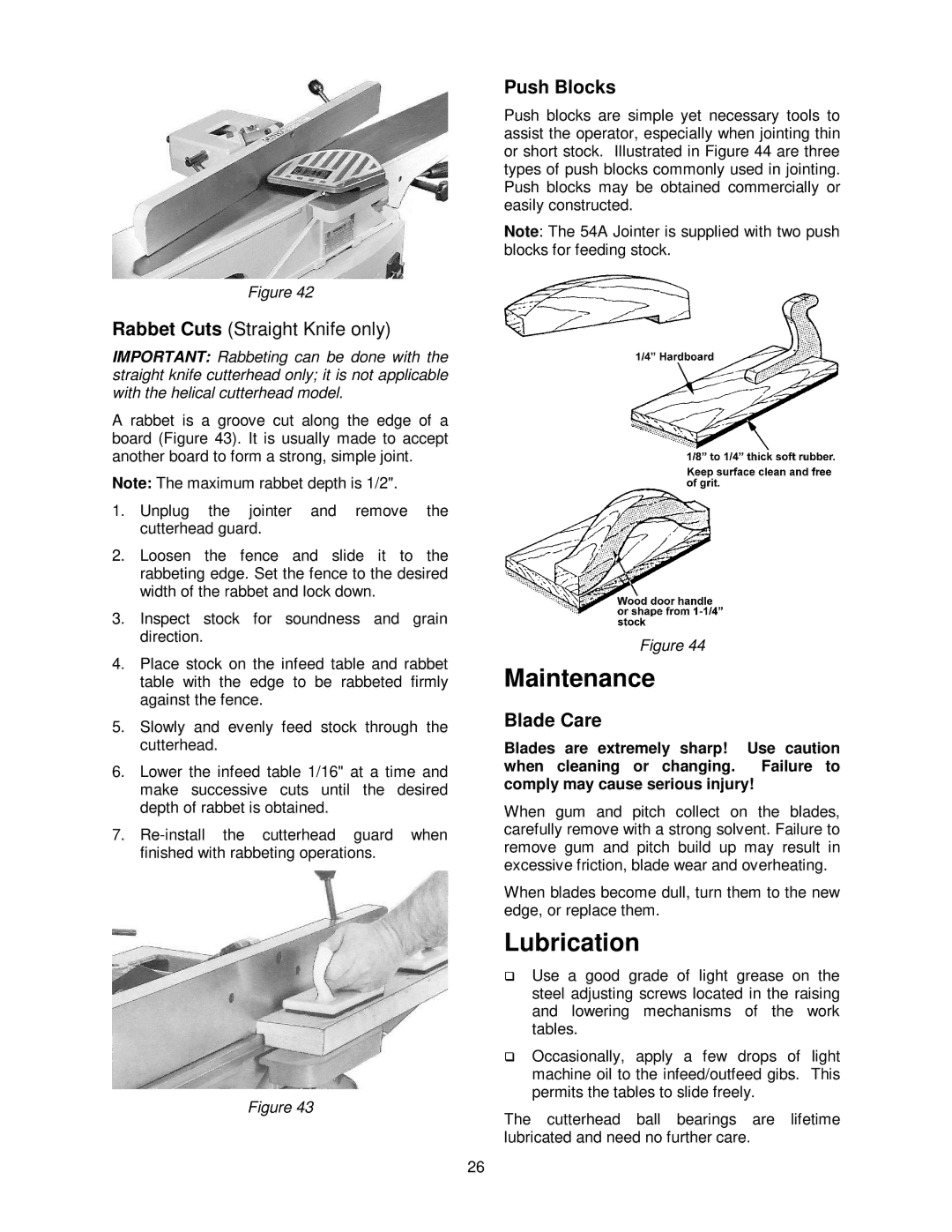

Push Blocks

Push blocks are simple yet necessary tools to assist the operator, especially when jointing thin or short stock. Illustrated in Figure 44 are three types of push blocks commonly used in jointing. Push blocks may be obtained commercially or easily constructed.

Note: The 54A Jointer is supplied with two push blocks for feeding stock.

Figure 44

Maintenance

Blade Care

Blades are extremely sharp! Use caution when cleaning or changing. Failure to comply may cause serious injury!

When gum and pitch collect on the blades, carefully remove with a strong solvent. Failure to remove gum and pitch build up may result in excessive friction, blade wear and overheating.

When blades become dull, turn them to the new edge, or replace them.

Lubrication

Use a good grade of light grease on the steel adjusting screws located in the raising and lowering mechanisms of the work tables.

Occasionally, apply a few drops of light machine oil to the infeed/outfeed gibs. This permits the tables to slide freely.

The cutterhead ball bearings are lifetime lubricated and need no further care.

26