2.Knives must be set in the cutterhead so that the highest point of their arc is level with the the outfeed table.

3.Knives must be parallel with the outfeed table across the entire length of the knives.

These alignments are explained below.

Setting Tables Parallel

For optimum performance of the jointer, the infeed and outfeed tables must be parallel front-

The tables have been set parallel at the factory, but they should be

The following procedure uses a steel straight edge to set the tables, which should be accurate enough for most purposes.

This procedure demonstrates how to set the parallelism of the outfeed table; the procedure for the infeed table will be identical.

1.Disconnect jointer from power source.

2.Remove the cutterhead guard by loosening the locking handle (see Figure 6) and lifting the guard shaft out of the hole.

3.Slide the fence assembly back as far as it will go, or remove it from the machine entirely.

4.Loosen the locking handle on the outfeed table (see A, Figure 23). Use the lifting handle (B, Figure 23) to raise the outfeed table higher than the cutterhead.

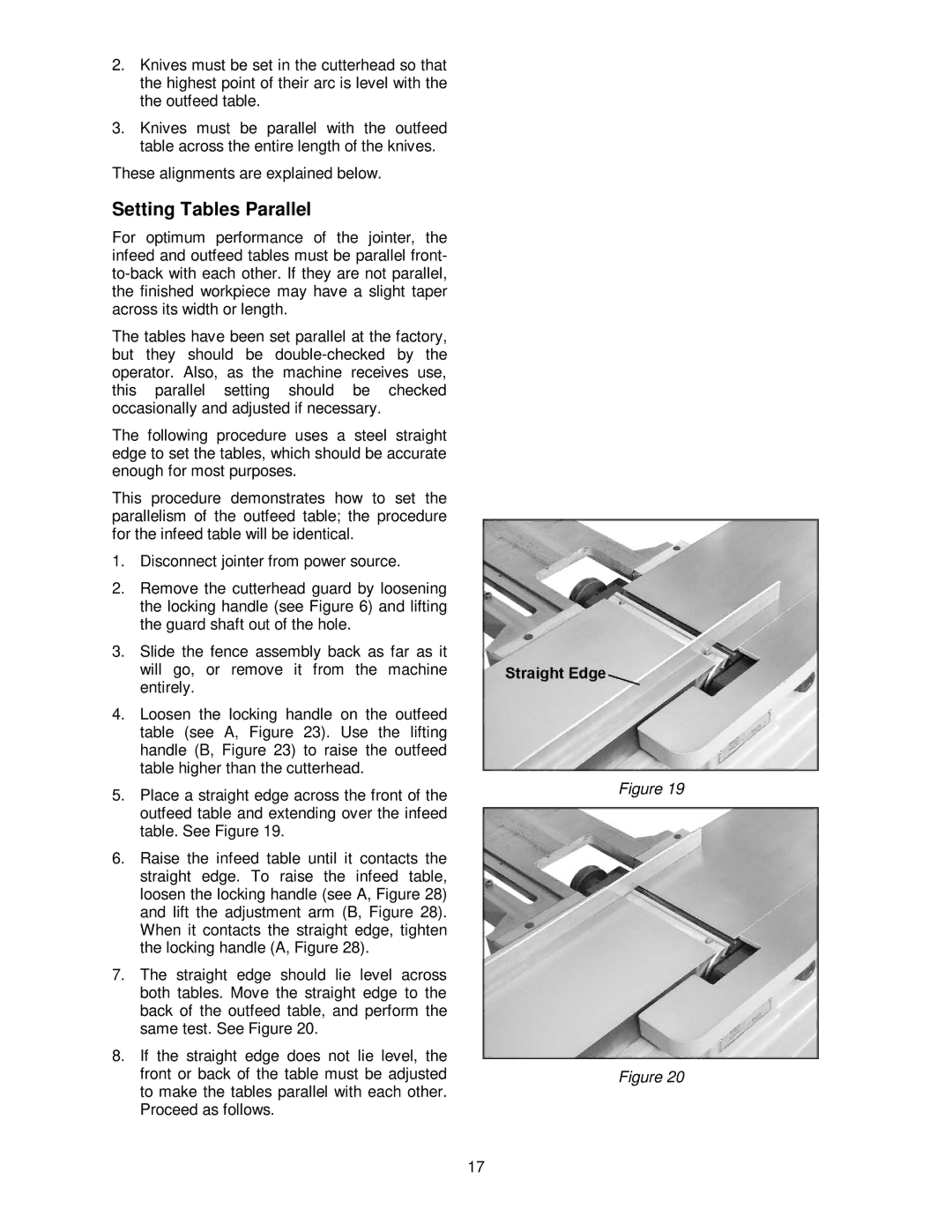

5.Place a straight edge across the front of the outfeed table and extending over the infeed table. See Figure 19.

6.Raise the infeed table until it contacts the straight edge. To raise the infeed table, loosen the locking handle (see A, Figure 28) and lift the adjustment arm (B, Figure 28). When it contacts the straight edge, tighten the locking handle (A, Figure 28).

7.The straight edge should lie level across both tables. Move the straight edge to the back of the outfeed table, and perform the same test. See Figure 20.

8.If the straight edge does not lie level, the front or back of the table must be adjusted to make the tables parallel with each other. Proceed as follows.

Figure 19

Figure 20

17