blade’s gullet (curved area at base of tooth). See Figure 24.

Figure 24

6.Tighten lock knob (F) to secure this position.

7.Loosen lock knob (G) for one of the guide bearings.

8.The guide bearing rotates on an eccentric shaft. Adjust guide bearing by rotating the knurled knob (H) with a 5mm hex key, until guide bearing is approximately 0.004” from blade. A quick way to achieve this spacing is by placing a single thickness of a crisp dollar bill (a dollar bill is approximately 0.004” thick) between blade and guide bearing. See Figure 25. Adjust guide bearing until it just lightly grips the dollar bill.

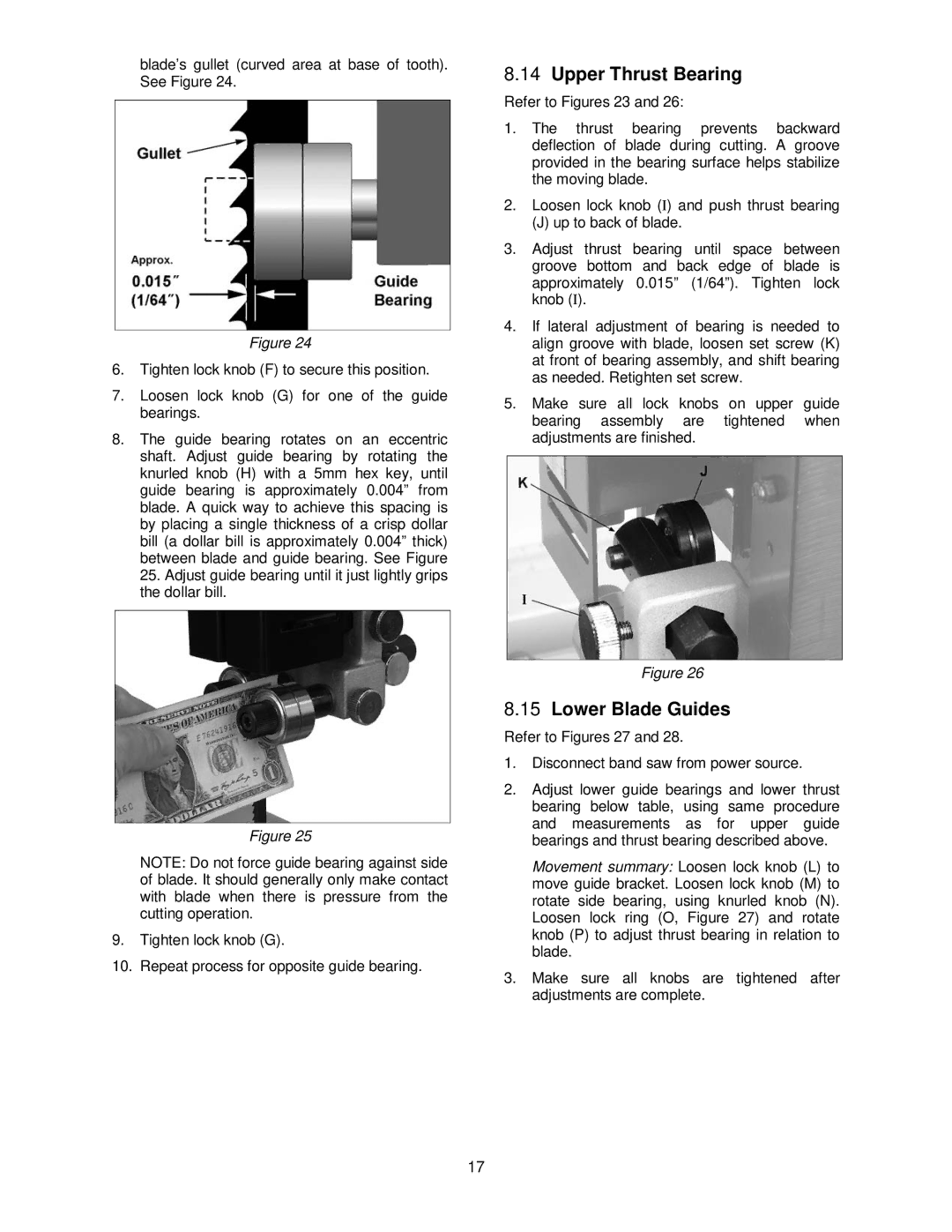

8.14Upper Thrust Bearing

Refer to Figures 23 and 26:

1.The thrust bearing prevents backward deflection of blade during cutting. A groove provided in the bearing surface helps stabilize the moving blade.

2.Loosen lock knob (I) and push thrust bearing

(J) up to back of blade.

3.Adjust thrust bearing until space between groove bottom and back edge of blade is approximately 0.015” (1/64”). Tighten lock knob (I).

4.If lateral adjustment of bearing is needed to align groove with blade, loosen set screw (K) at front of bearing assembly, and shift bearing as needed. Retighten set screw.

5.Make sure all lock knobs on upper guide bearing assembly are tightened when adjustments are finished.

Figure 25

NOTE: Do not force guide bearing against side of blade. It should generally only make contact with blade when there is pressure from the cutting operation.

9.Tighten lock knob (G).

10.Repeat process for opposite guide bearing.

Figure 26

8.15Lower Blade Guides

Refer to Figures 27 and 28.

1.Disconnect band saw from power source.

2.Adjust lower guide bearings and lower thrust bearing below table, using same procedure and measurements as for upper guide bearings and thrust bearing described above.

Movement summary: Loosen lock knob (L) to move guide bracket. Loosen lock knob (M) to rotate side bearing, using knurled knob (N). Loosen lock ring (O, Figure 27) and rotate knob (P) to adjust thrust bearing in relation to blade.

3.Make sure all knobs are tightened after adjustments are complete.

17