Figure 6 – vertical position

The aluminum fence plate can be installed in one of two positions; vertically (resaw position), as shown in Figure 6; or horizontally as shown in Figure 7.

Horizontal position is useful for smaller workpieces. (The zero setting of the cursor cannot be used with horizontal fence position.)

Figure 7 – horizontal position

8.3Fence to Table Clearance

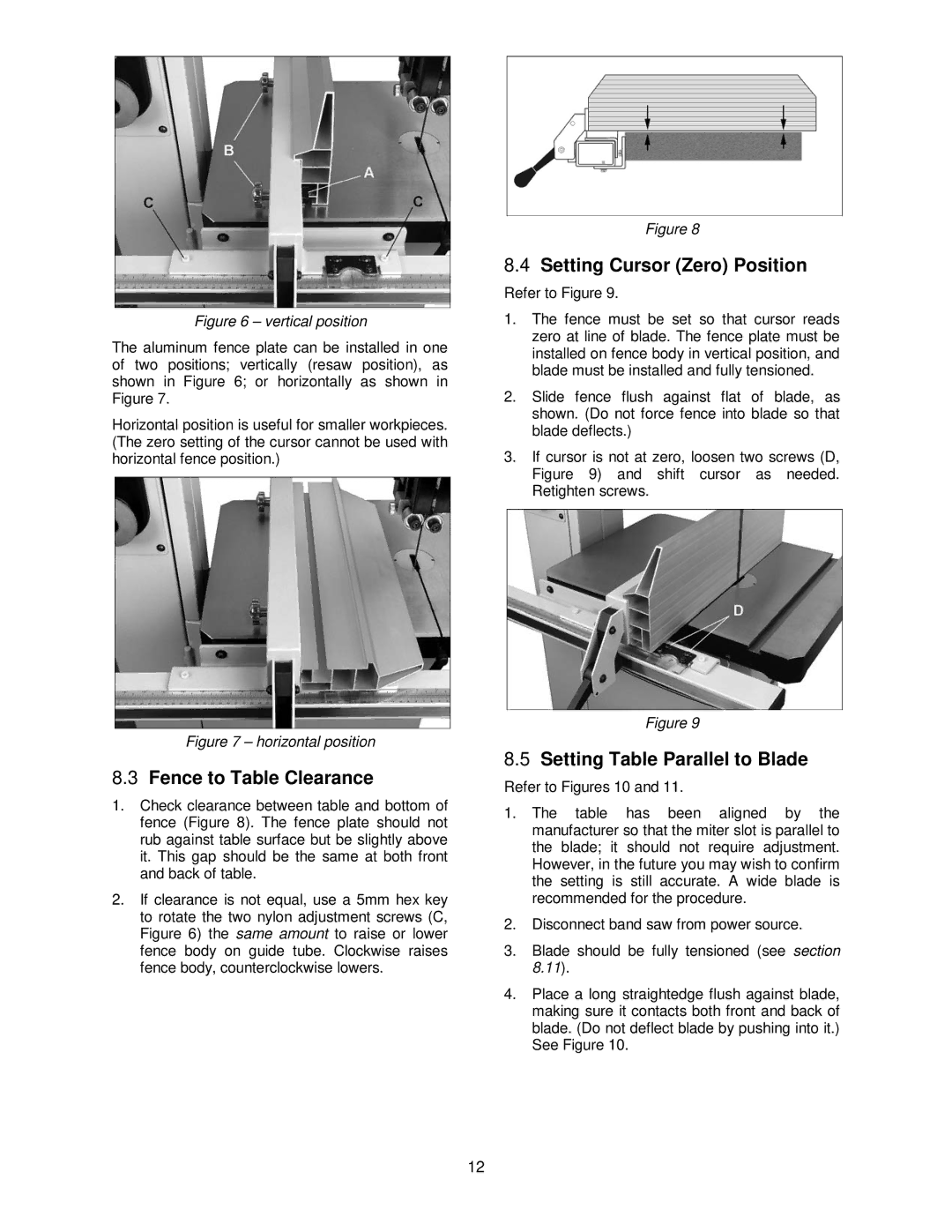

1.Check clearance between table and bottom of fence (Figure 8). The fence plate should not rub against table surface but be slightly above it. This gap should be the same at both front and back of table.

2.If clearance is not equal, use a 5mm hex key to rotate the two nylon adjustment screws (C, Figure 6) the same amount to raise or lower fence body on guide tube. Clockwise raises fence body, counterclockwise lowers.

12

Figure 8

8.4Setting Cursor (Zero) Position

Refer to Figure 9.

1.The fence must be set so that cursor reads zero at line of blade. The fence plate must be installed on fence body in vertical position, and blade must be installed and fully tensioned.

2.Slide fence flush against flat of blade, as shown. (Do not force fence into blade so that blade deflects.)

3.If cursor is not at zero, loosen two screws (D, Figure 9) and shift cursor as needed. Retighten screws.

Figure 9

8.5Setting Table Parallel to Blade

Refer to Figures 10 and 11.

1.The table has been aligned by the manufacturer so that the miter slot is parallel to the blade; it should not require adjustment. However, in the future you may wish to confirm the setting is still accurate. A wide blade is recommended for the procedure.

2.Disconnect band saw from power source.

3.Blade should be fully tensioned (see section 8.11).

4.Place a long straightedge flush against blade, making sure it contacts both front and back of blade. (Do not deflect blade by pushing into it.) See Figure 10.