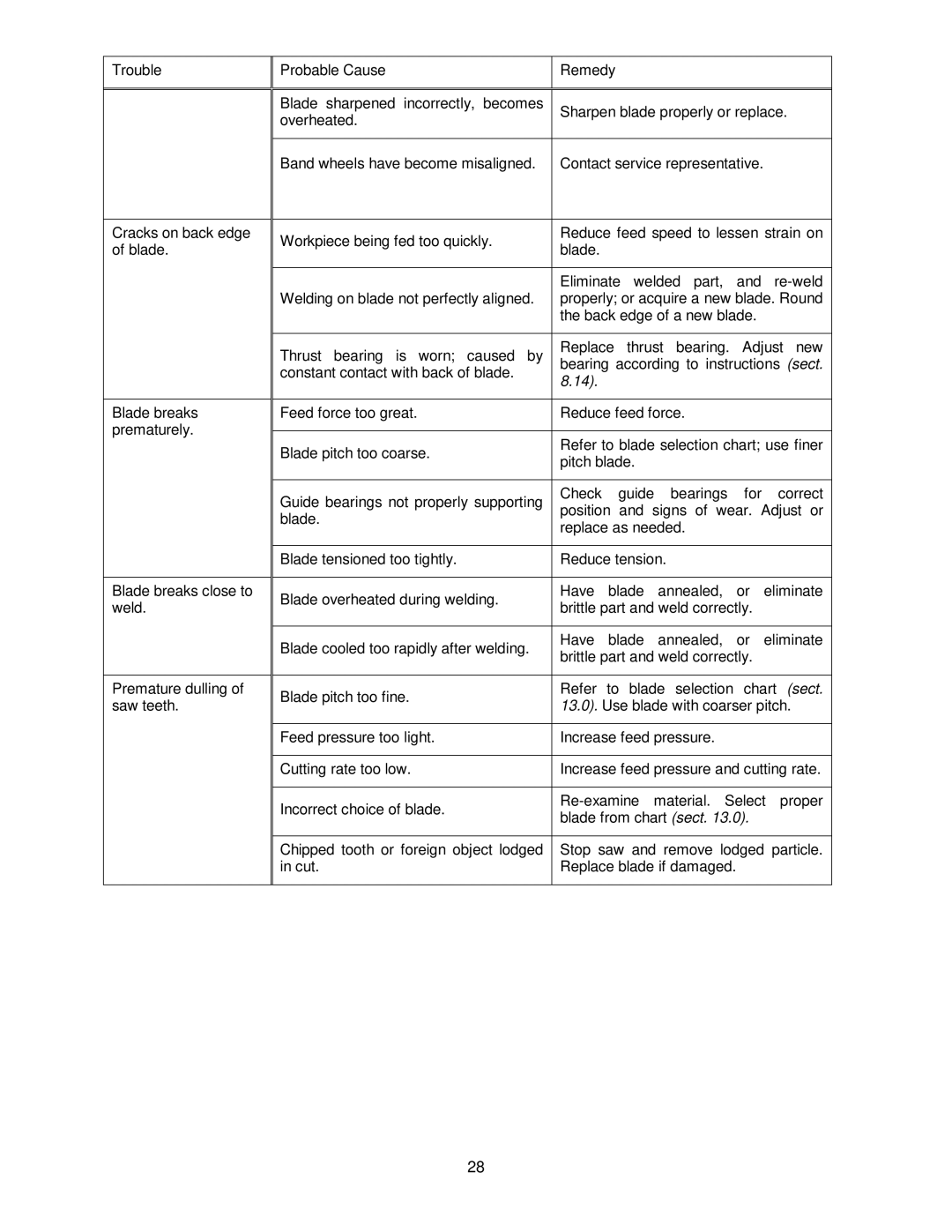

Trouble

Cracks on back edge of blade.

Blade breaks prematurely.

Blade breaks close to weld.

Premature dulling of saw teeth.

Probable Cause |

| Remedy |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |

Blade sharpened | incorrectly, becomes | Sharpen blade properly or replace. | |||||||||

overheated. |

| ||||||||||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

| ||||||||

Band wheels have become misaligned. | Contact service representative. |

|

| ||||||||

|

|

| |||||||||

Workpiece being fed too quickly. | Reduce feed speed to lessen strain on | ||||||||||

blade. |

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| ||

|

|

| |||||||||

|

| Eliminate welded part, and | |||||||||

Welding on blade not perfectly aligned. | properly; or acquire a new blade. Round | ||||||||||

|

| the back edge of a new blade. |

|

| |||||||

|

|

|

|

|

| ||||||

Thrust bearing | is worn; caused by | Replace | thrust | bearing. | Adjust new | ||||||

bearing according to instructions (sect. | |||||||||||

constant contact with back of blade. | |||||||||||

8.14). |

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

| ||||||

Feed force too great. | Reduce feed force. |

|

|

|

| ||||||

|

|

| |||||||||

Blade pitch too coarse. | Refer to blade selection chart; use finer | ||||||||||

pitch blade. |

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

| ||||

Guide bearings not properly supporting | Check | guide | bearings | for |

| correct | |||||

position | and | signs of | wear. Adjust or | ||||||||

blade. |

| ||||||||||

| replace as needed. |

|

|

|

| ||||||

|

|

|

|

|

| ||||||

|

|

|

|

|

|

| |||||

Blade tensioned too tightly. | Reduce tension. |

|

|

|

|

| |||||

|

|

|

|

|

|

| |||||

Blade overheated during welding. | Have | blade | annealed, | or | eliminate | ||||||

brittle part and weld correctly. |

|

| |||||||||

|

|

|

| ||||||||

|

|

|

|

|

|

| |||||

Blade cooled too rapidly after welding. | Have | blade | annealed, | or | eliminate | ||||||

brittle part and weld correctly. |

|

| |||||||||

|

|

|

| ||||||||

|

|

|

|

|

|

|

| ||||

Blade pitch too fine. | Refer | to | blade | selection | chart | (sect. | |||||

13.0). Use blade with coarser pitch. | |||||||||||

|

| ||||||||||

|

|

|

|

|

| ||||||

Feed pressure too light. | Increase feed pressure. |

|

|

|

| ||||||

|

| ||||||||||

Cutting rate too low. | Increase feed pressure and cutting rate. | ||||||||||

|

|

|

|

|

| ||||||

Incorrect choice of blade. | material. | Select | proper | ||||||||

blade from chart (sect. 13.0). |

|

| |||||||||

|

|

|

| ||||||||

|

| ||||||||||

Chipped tooth or foreign object lodged | Stop saw and remove lodged particle. | ||||||||||

in cut. |

| Replace blade if damaged. |

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

| |

28