INSTALLATION

DRAFT DIVERTER

CONNECTION

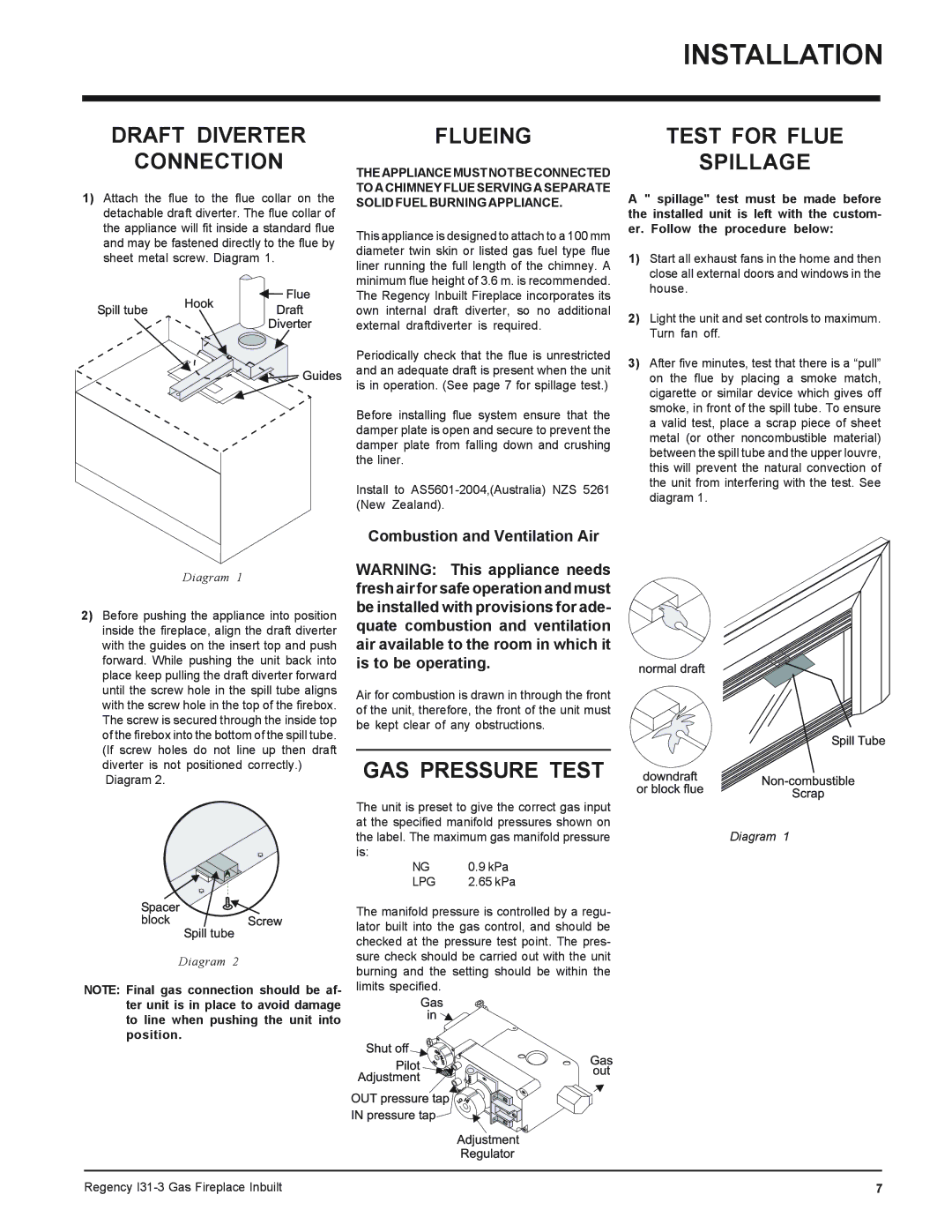

1)Attach the flue to the flue collar on the detachable draft diverter. The flue collar of the appliance will fit inside a standard flue and may be fastened directly to the flue by sheet metal screw. Diagram 1.

Diagram 1

2)Before pushing the appliance into position inside the fireplace, align the draft diverter with the guides on the insert top and push forward. While pushing the unit back into place keep pulling the draft diverter forward until the screw hole in the spill tube aligns with the screw hole in the top of the firebox. The screw is secured through the inside top of the firebox into the bottom of the spill tube. (If screw holes do not line up then draft diverter is not positioned correctly.)

Diagram 2.

Diagram 2

NOTE: Final gas connection should be af- ter unit is in place to avoid damage to line when pushing the unit into position.

FLUEING

THEAPPLIANCEMUSTNOTBECONNECTED TO A CHIMNEY FLUE SERVING A SEPARATE SOLID FUEL BURNING APPLIANCE.

This appliance is designed to attach to a 100 mm diameter twin skin or listed gas fuel type flue liner running the full length of the chimney. A minimum flue height of 3.6 m. is recommended. The Regency Inbuilt Fireplace incorporates its own internal draft diverter, so no additional external draftdiverter is required.

Periodically check that the flue is unrestricted and an adequate draft is present when the unit is in operation. (See page 7 for spillage test.)

Before installing flue system ensure that the damper plate is open and secure to prevent the damper plate from falling down and crushing the liner.

Install to

Combustion and Ventilation Air

WARNING: This appliance needs fresh air for safe operation and must be installed with provisions for ade- quate combustion and ventilation air available to the room in which it is to be operating.

Air for combustion is drawn in through the front of the unit, therefore, the front of the unit must be kept clear of any obstructions.

GAS PRESSURE TEST

The unit is preset to give the correct gas input at the specified manifold pressures shown on the label. The maximum gas manifold pressure is:

NG | 0.9 kPa |

LPG | 2.65 kPa |

The manifold pressure is controlled by a regu- lator built into the gas control, and should be checked at the pressure test point. The pres- sure check should be carried out with the unit burning and the setting should be within the limits specified.

TEST FOR FLUE

SPILLAGE

A " spillage" test must be made before the installed unit is left with the custom- er. Follow the procedure below:

1)Start all exhaust fans in the home and then close all external doors and windows in the house.

2)Light the unit and set controls to maximum. Turn fan off.

3)After five minutes, test that there is a “pull” on the flue by placing a smoke match, cigarette or similar device which gives off smoke, in front of the spill tube. To ensure a valid test, place a scrap piece of sheet metal (or other noncombustible material) between the spill tube and the upper louvre, this will prevent the natural convection of the unit from interfering with the test. See diagram 1.

Diagram 1

Regency | 7 |