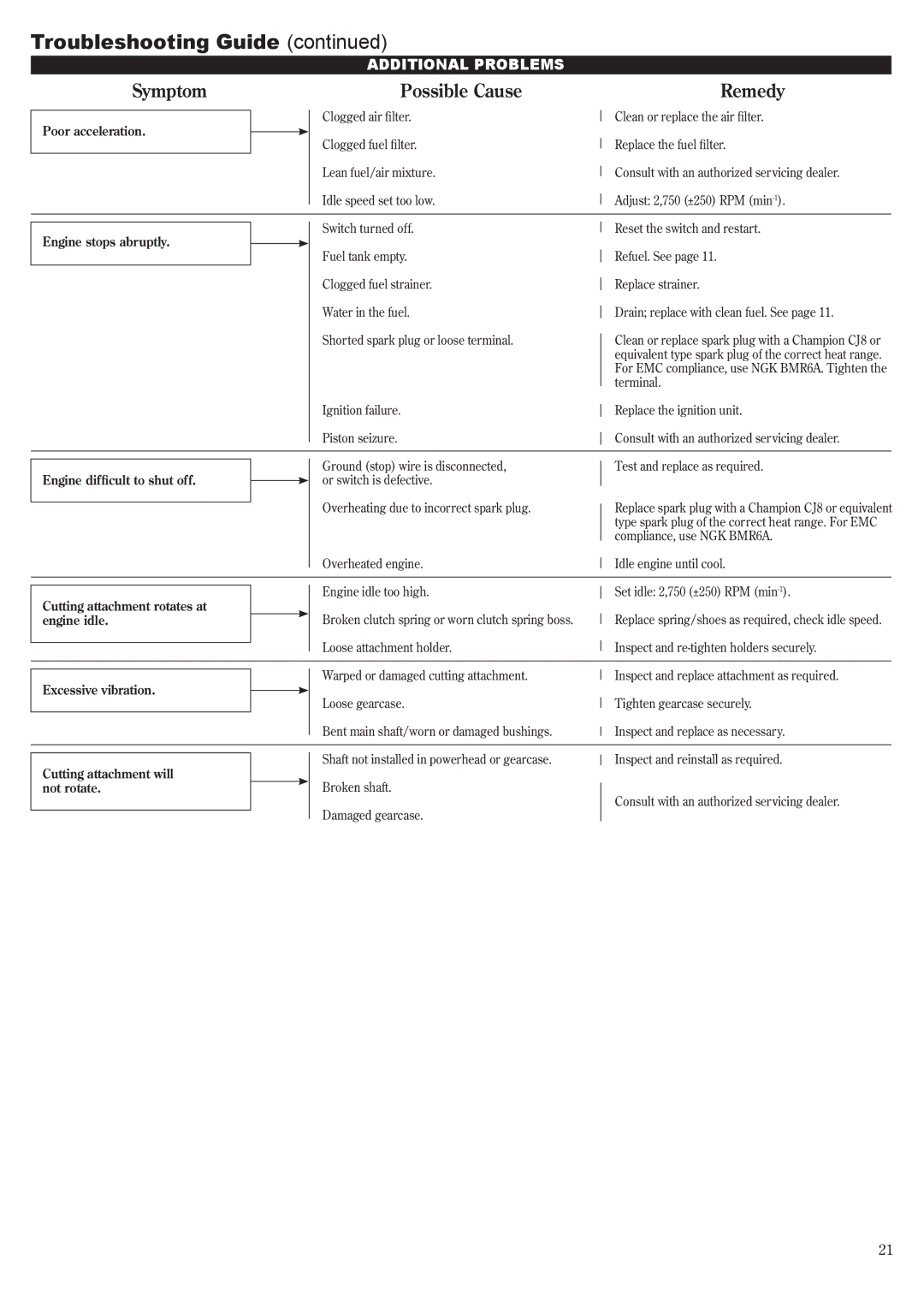

Troubleshooting Guide (continued)

|

|

|

|

|

|

|

|

| ADDITIONAL PROBLEMS |

|

|

Symptom |

|

| Possible Cause |

| Remedy |

|

|

| Clogged air filter. |

| Clean or replace the air filter. |

Poor acceleration. |

|

|

| ||

|

| Clogged fuel filter. |

| Replace the fuel filter. | |

|

|

| |||

|

|

|

| ||

|

|

|

| ||

|

|

| Lean fuel/air mixture. |

| Consult with an authorized servicing dealer. |

|

|

|

| ||

|

|

|

| ||

|

|

| Idle speed set too low. |

| Adjust: 2,750 (±250) RPM |

|

|

|

| ||

|

|

|

| ||

|

|

|

|

|

|

|

|

| Switch turned off. |

| Reset the switch and restart. |

Engine stops abruptly. |

|

|

| ||

|

|

| |||

|

| Fuel tank empty. |

| Refuel. See page 11. | |

|

|

| |||

|

|

|

| ||

|

|

| Clogged fuel strainer. |

| Replace strainer. |

|

|

|

| ||

|

|

|

| ||

|

|

| Water in the fuel. |

| Drain; replace with clean fuel. See page 11. |

|

|

|

| ||

|

|

| Shorted spark plug or loose terminal. |

| Clean or replace spark plug with a Champion CJ8 or |

|

|

|

| ||

|

|

|

|

| equivalent type spark plug of the correct heat range. |

|

|

|

|

| For EMC compliance, use NGK BMR6A. Tighten the |

|

|

|

|

| terminal. |

|

|

|

|

| |

|

|

| Ignition failure. |

| Replace the ignition unit. |

|

|

|

| ||

|

|

| Piston seizure. |

| Consult with an authorized servicing dealer. |

|

|

|

| ||

|

|

|

|

|

|

|

|

| Ground (stop) wire is disconnected, |

| Test and replace as required. |

|

|

|

| ||

Engine difficult to shut off. |

|

| or switch is defective. |

|

|

|

|

| Overheating due to incorrect spark plug. |

| Replace spark plug with a Champion CJ8 or equivalent |

|

|

|

| ||

|

|

|

|

| type spark plug of the correct heat range. For EMC |

|

|

|

|

| compliance, use NGK BMR6A. |

|

|

| Overheated engine. |

| Idle engine until cool. |

|

|

|

| ||

|

|

|

| ||

|

|

|

|

|

|

|

|

| Engine idle too high. |

| Set idle: 2,750 (±250) RPM |

Cutting attachment rotates at |

|

|

| ||

|

| Broken clutch spring or worn clutch spring boss. |

| Replace spring/shoes as required, check idle speed. | |

engine idle. |

|

|

| ||

|

|

| |||

|

|

| |||

|

|

| Loose attachment holder. |

| Inspect and |

|

|

|

| ||

|

|

|

| ||

|

|

|

|

|

|

|

|

| Warped or damaged cutting attachment. |

| Inspect and replace attachment as required. |

Excessive vibration. |

|

|

| ||

|

|

| |||

|

| Loose gearcase. |

| Tighten gearcase securely. | |

|

|

| |||

|

|

|

| ||

|

|

|

| ||

|

|

| Bent main shaft/worn or damaged bushings. |

| Inspect and replace as necessary. |

|

| ||||

|

|

|

| ||

|

|

|

|

|

|

|

|

| Shaft not installed in powerhead or gearcase. |

| Inspect and reinstall as required. |

Cutting attachment will |

|

|

| ||

|

| Broken shaft. |

|

| |

not rotate. |

|

|

| Consult with an authorized servicing dealer. | |

|

|

| |||

|

|

| Damaged gearcase. |

| |

|

|

|

|

| |

|

|

|

|

|

21