3989 specifications

The Simer Pumps 3989 series is a powerful and versatile solution designed for a variety of applications, including residential, agricultural, and light commercial uses. This pump is known for its reliability and efficiency, making it a favored choice among homeowners and professionals alike.One of the standout features of the Simer Pumps 3989 is its robust construction. Built with durable materials, the pump can withstand harsh operating conditions while providing exceptional performance. The casing is typically made from corrosion-resistant materials, ensuring longevity and maintaining its efficiency over time.

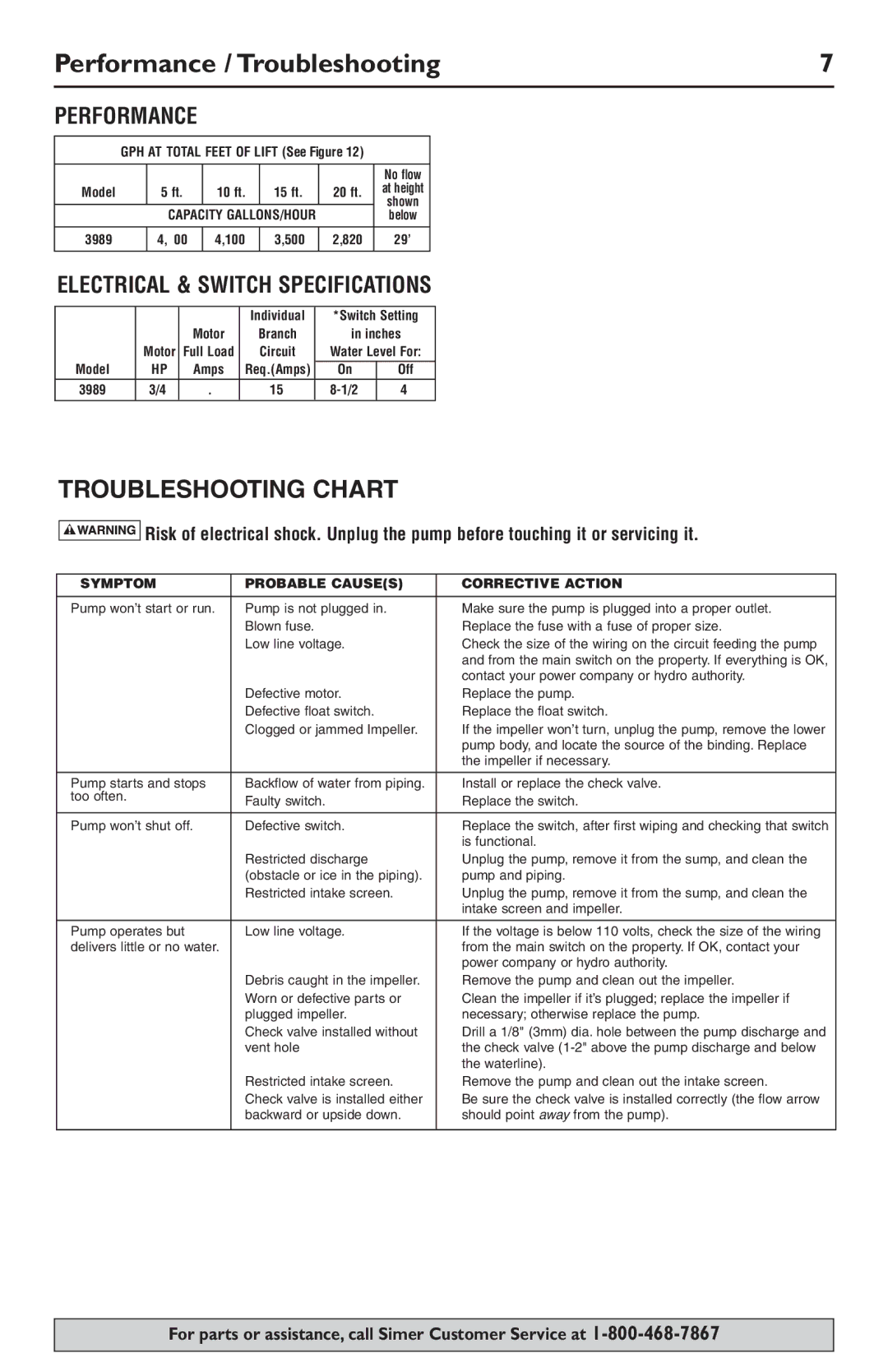

The 3989 series is equipped with a high-efficiency motor that offers a combination of power and energy savings. This motor operates quietly, reducing noise pollution in residential areas. The pump is designed to move a significant volume of water quickly, making it suitable for tasks such as draining flooded basements, irrigation, and general water transfer. With a flow rate that can reach impressive levels, the Simer 3989 effectively meets the demands of various projects.

In terms of technology, the Simer Pumps 3989 incorporates a thermal overload protection system. This feature prevents the motor from overheating, thus enhancing safety and prolonging the pump's lifespan. Additionally, the pump is designed for easy maintenance, with accessible components that facilitate routine checks and repairs.

Another characteristic that sets the Simer Pumps 3989 apart is its user-friendly installation process. The pump is compatible with standard plumbing fittings, allowing for a straightforward setup without the need for specialized tools. This ease of installation is a valuable advantage for DIY enthusiasts and professionals who need to save time on job sites.

Furthermore, the Simer 3989 pump operates efficiently across a range of temperatures, making it suitable for both warm and cold climates. Its versatility extends to various applications, from home use to agricultural settings, where reliable water movement is critical.

Overall, the Simer Pumps 3989 is an excellent choice for anyone in need of a dependable, high-performance water pump. With its strong construction, efficient design, and user-friendly features, it continues to be a popular option for diverse pumping needs, delivering a blend of durability, efficiency, and performance all in one package.