SECTION 3 – MAINTENANCE

3.2.8.Check Interlocks

The machine is equipped with interlocks that prevent the engine from cranking or starting unless the brake is fully depressed and the transmission is in Neutral. It is also equipped with an operator presence sensor that will cause the engine to die if the operator attempts to leave the seat without setting the park brake. On models equipped with the POWERLINK Generator System, the interlock kills the engine if the parking brake is disengaged or the transmission is engaged while the generator is being operated. The interlocks were designed for the safety of the operator and others. Do not modify or defeat the interlocks. Do not operate the machine if interlocks are not functioning properly.

1.Move machine to a flat, open area free of obstacles, children and others.

2.Shift transmission to Forward.

3.Set park brake.

4.Turn key to “Start”. Engine must not crank.

5.Shift transmission to Reverse.

6.Turn key to “Start”. Engine must not crank.

7.Shift transmission to neutral.

8.Release park brake.

9.Turn key to “Start”. Engine must not crank.

10.Set park brake and shift transmission to Neutral.

11.Start engine.

12.With engine at idle, release park brake.

13.Carefully grasp the steering wheel and raise up slightly out of the operator’s seat. The engine must begin to die. (The engine can continue to run if you sit back down in the seat before it dies completely.) Set park brake.

14.Shift Transmission to Forward.

15.Carefully grasp the steering wheel and raise up slightly out of the operator’s seat. The engine must begin to die. (The engine can continue to run if you sit back down in the seat before it dies completely.)

16.Shift Transmission to Reverse.

17.Carefully grasp the steering wheel and raise up slightly out of the operator’s seat. The engine must begin to die. (The engine can continue to

run if you sit back down in the seat before it dies completely.)

WARNING

DO NOT operate machine if interlocks are not functioning properly. Contact your local authorized dealer for assistance.

3.3SERVICE – EVERY 25 OPERATING HOURS

3.3.1.Perform all service required after the first 5 hours of operation – Refer to Section “SERVICE –

AFTER FIRST 5 HOURS”.

3.3.2.Check Battery Charge Level.

NOTE: The battery in this machine is

1.Remove seat knobs and carefully tilt forward to expose battery.

2.Remove battery, check voltage, and charge if necessary. Refer to Section ‘Adjustments and Repairs, Battery’.

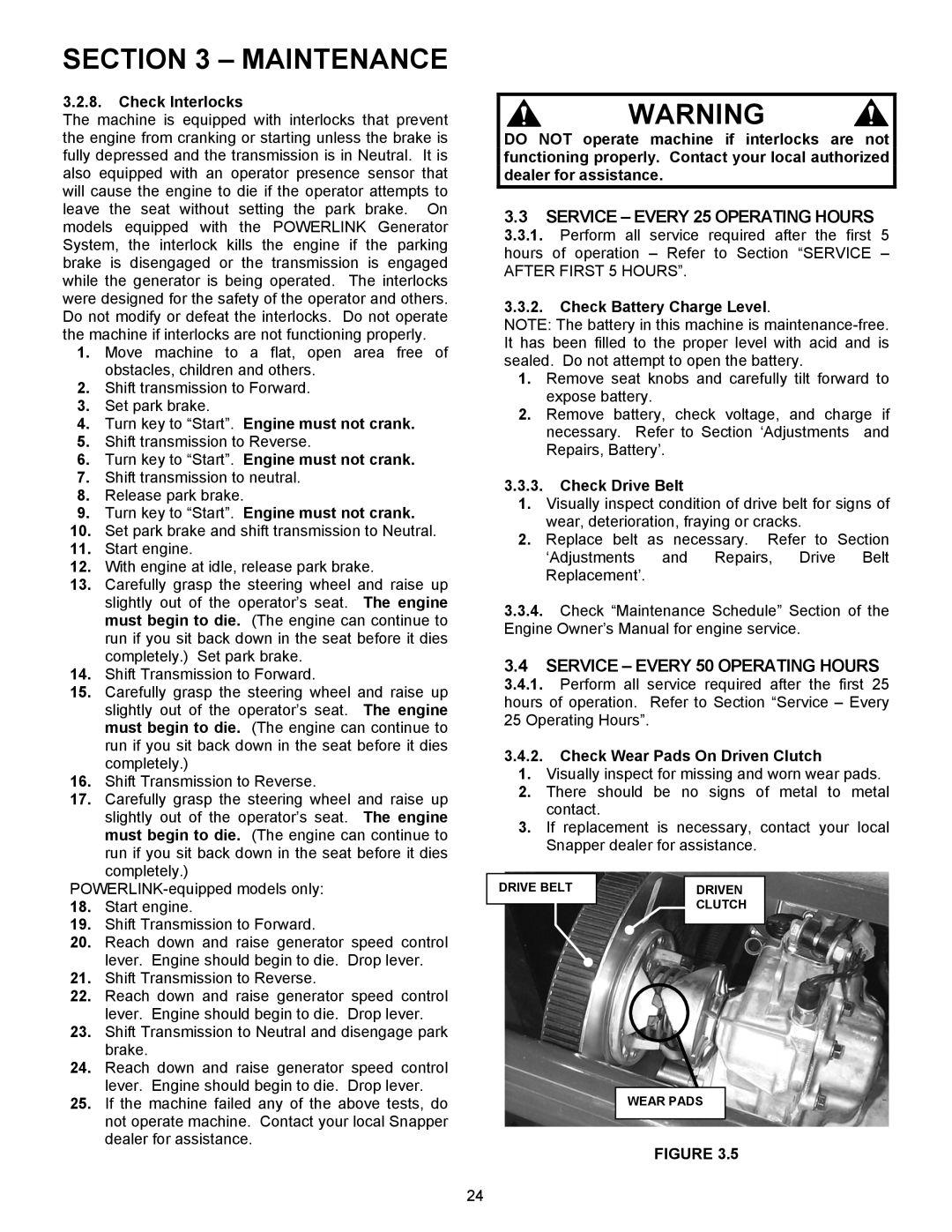

3.3.3.Check Drive Belt

1.Visually inspect condition of drive belt for signs of wear, deterioration, fraying or cracks.

2.Replace belt as necessary. Refer to Section ‘Adjustments and Repairs, Drive Belt Replacement’.

3.3.4.Check “Maintenance Schedule” Section of the Engine Owner’s Manual for engine service.

3.4SERVICE – EVERY 50 OPERATING HOURS

3.4.1.Perform all service required after the first 25 hours of operation. Refer to Section “Service – Every 25 Operating Hours”.

3.4.2.Check Wear Pads On Driven Clutch

1.Visually inspect for missing and worn wear pads.

2.There should be no signs of metal to metal contact.

3.If replacement is necessary, contact your local Snapper dealer for assistance.

18.Start engine.

19.Shift Transmission to Forward.

20.Reach down and raise generator speed control lever. Engine should begin to die. Drop lever.

21.Shift Transmission to Reverse.

22.Reach down and raise generator speed control lever. Engine should begin to die. Drop lever.

23.Shift Transmission to Neutral and disengage park brake.

24.Reach down and raise generator speed control lever. Engine should begin to die. Drop lever.

25.If the machine failed any of the above tests, do not operate machine. Contact your local Snapper dealer for assistance.

DRIVE BELT

21

24

DRIVEN

CLUTCH

WEAR PADS

FIGURE 3.5