Simrad Reversible Pump RPU80/160/300

4 INSTALLATION

4.1 Mechanical Installation

Siting

The pump unit should be sited where it is most practical between rudder cylinder and helm pump, however, it should not be mounted in a wet area. If the pump unit is sited higher than the rudder cylinder, air bubbles in the oil coming from the rudder cylinder could pass through the pump unit on the way to the expansion tank in the steering wheel pump. This will disturb the oil flow as the air bubbles pass through.

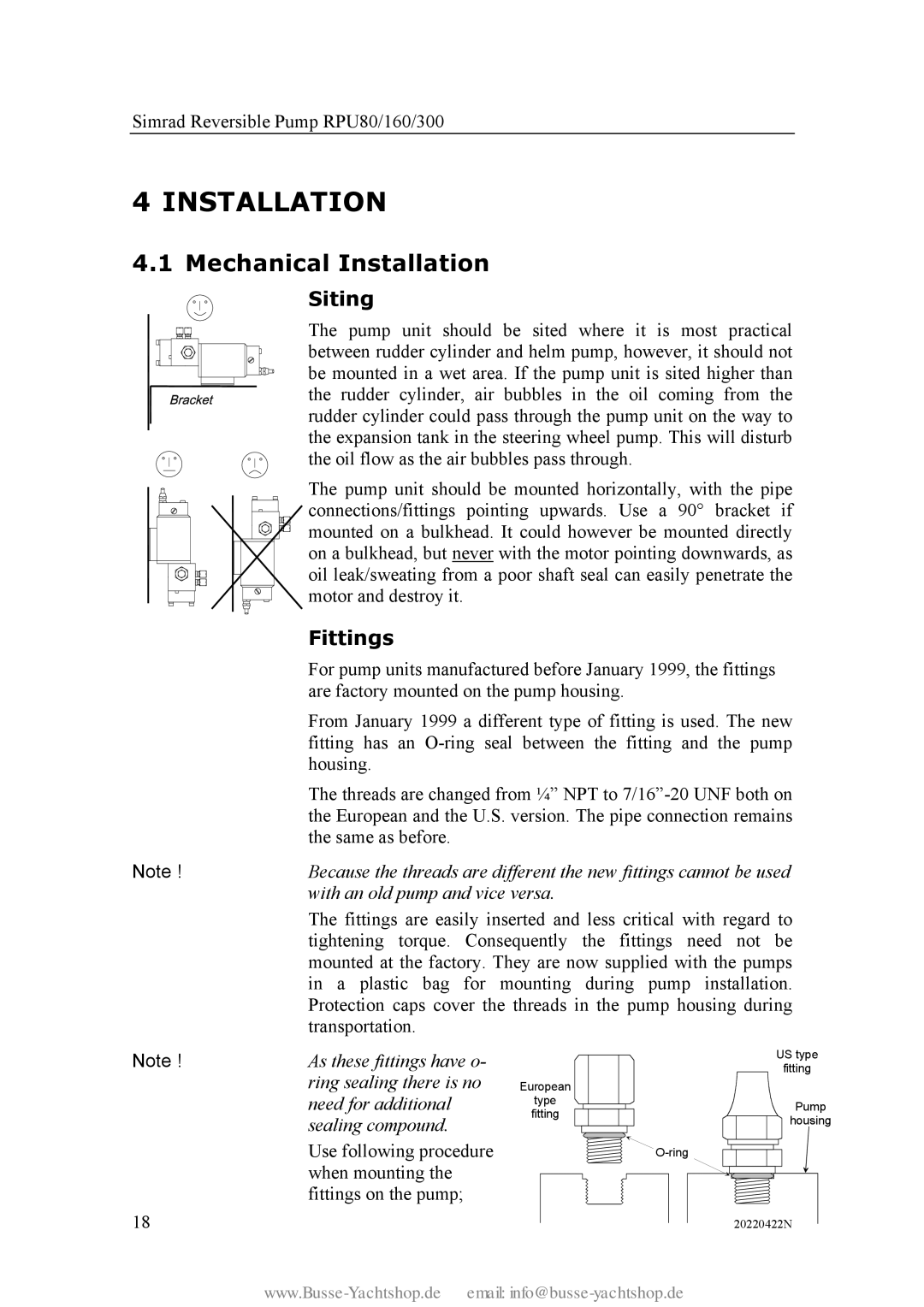

The pump unit should be mounted horizontally, with the pipe connections/fittings pointing upwards. Use a 90° bracket if mounted on a bulkhead. It could however be mounted directly on a bulkhead, but never with the motor pointing downwards, as oil leak/sweating from a poor shaft seal can easily penetrate the motor and destroy it.

| Fittings |

| For pump units manufactured before January 1999, the fittings |

| are factory mounted on the pump housing. |

| From January 1999 a different type of fitting is used. The new |

| fitting has an |

| housing. |

| The threads are changed from ¼” NPT to |

| the European and the U.S. version. The pipe connection remains |

| the same as before. |

Note ! | Because the threads are different the new fittings cannot be used |

| with an old pump and vice versa. |

| The fittings are easily inserted and less critical with regard to |

| tightening torque. Consequently the fittings need not be |

| mounted at the factory. They are now supplied with the pumps |

| in a plastic bag for mounting during pump installation. |

| Protection caps cover the threads in the pump housing during |

| transportation. |

Note ! | As these fittings have o- |

| ring sealing there is no |

| need for additional |

| sealing compound. |

| Use following procedure |

| when mounting the |

| fittings on the pump; |

18 |

|

| US type | |

| fitting | |

European |

| |

type | Pump | |

fitting | ||

housing | ||

| ||

|