Wiring ( continued )

Power supply wiring (Power Block)

Power supply wiring (Power Block)

When operating

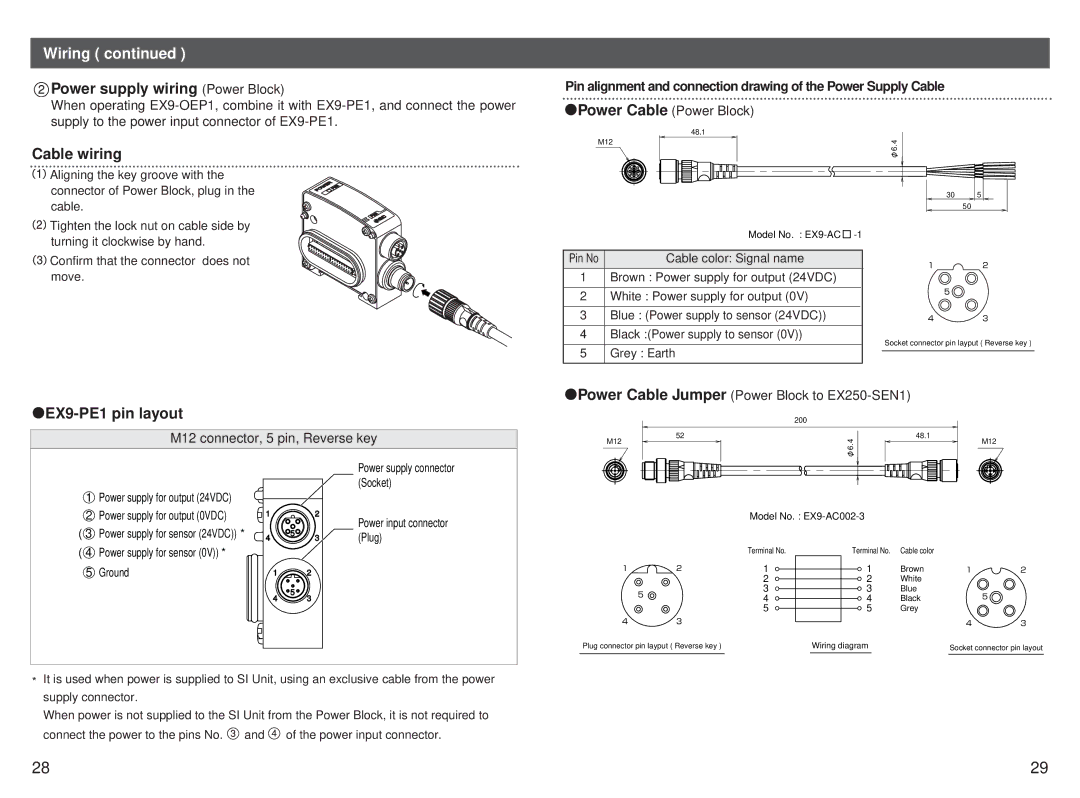

Cable wiring

![]()

![]()

![]() Aligning the key groove with the connector of Power Block, plug in the cable.

Aligning the key groove with the connector of Power Block, plug in the cable.

Pin alignment and connection drawing of the Power Supply Cable

Power Cable (Power Block)

Power Cable (Power Block)

48.1

M126.4 φ

30 5

50

![]()

![]() Tighten the lock nut on cable side by turning it clockwise by hand.

Tighten the lock nut on cable side by turning it clockwise by hand.

![]()

![]() Confirm that the connector does not move.

Confirm that the connector does not move.

| Model No. : | |

|

|

|

Pin No | Cable color: Signal name | |

1 | Brown : Power supply for output (24VDC) | |

|

|

|

2 | White : Power supply for output (0V) | |

|

|

|

3 | Blue : (Power supply to sensor (24VDC)) | |

|

| |

4 | Black :(Power supply to sensor (0V)) | |

|

| |

5 | Grey : Earth | |

|

|

|

12

5

43

Socket connector pin layput ( Reverse key )

EX9-PE1

EX9-PE1

M12 connector, 5 pin, Reverse key

![]() Power Cable Jumper (Power Block to

Power Cable Jumper (Power Block to

| 200 |

|

52 |

| 48.1 |

M12 | φ6.4 | M12 |

|

|

1Power supply for output (24VDC)

2Power supply for output (0VDC)

12

Power supply connector (Socket)

Power input connector

Model No. :

( 3 Power supply for sensor (24VDC)) * ( 4 Power supply for sensor (0V)) *

5 Ground

5

43

1 2

5

4 3

(Plug)

|

| Terminal No. |

1 | 2 | 1 |

|

| 2 |

3

5 | 4 |

| 5 |

43

Plug connector pin layput ( Reverse key )

Terminal No. Cable color

1 | Brown | 1 | 2 |

2White

3Blue

4 | Black | 5 |

5Grey

4 3

Wiring diagram | Socket connector pin layout | |

|

|

|

*It is used when power is supplied to SI Unit, using an exclusive cable from the power supply connector.

When power is not supplied to the SI Unit from the Power Block, it is not required to connect the power to the pins No. ![]() and

and ![]() of the power input connector.

of the power input connector.

28 | 29 |