Model SB1018 | O P E R A T I O N | For Machines Mfg. Since 8/09 |

Blade Speed Chart

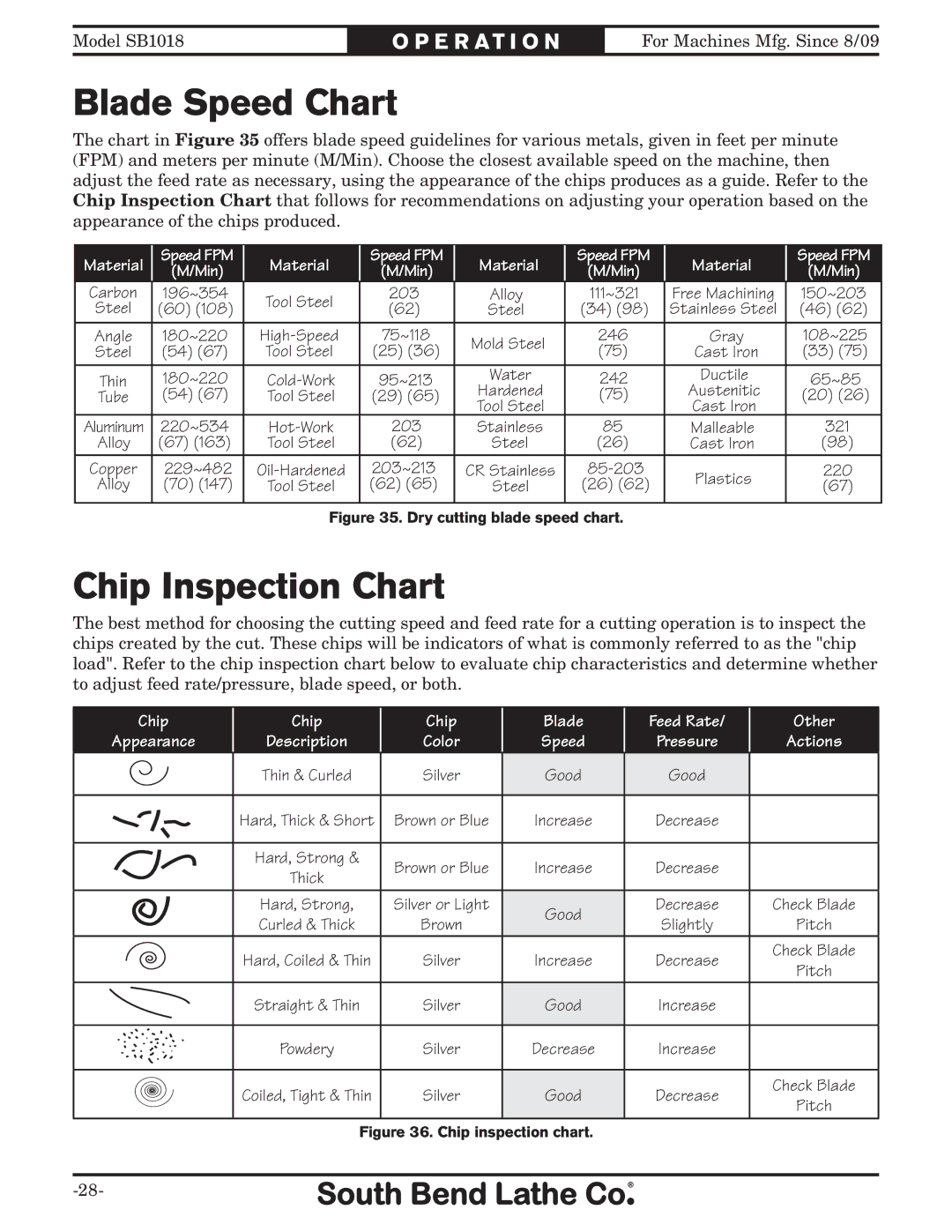

The chart in Figure 35 offers blade speed guidelines for various metals, given in feet per minute (FPM) and meters per minute (M/Min). Choose the closest available speed on the machine, then adjust the feed rate as necessary, using the appearance of the chips produces as a guide. Refer to the Chip Inspection Chart that follows for recommendations on adjusting your operation based on the appearance of the chips produced.

Material | Speed FPM | Material | Speed FPM | Material | Speed FPM | Material | Speed FPM | |

(M/Min) | (M/Min) | (M/Min) | (M/Min) | |||||

|

|

|

| |||||

Carbon | 196~354 | Tool Steel | 203 | Alloy | 111~321 | Free Machining | 150~203 | |

Steel | (60) (108) | (62) | Steel | (34) (98) | Stainless Steel | (46) (62) | ||

| ||||||||

Angle | 180~220 | 75~118 | Mold Steel | 246 | Gray | 108~225 | ||

Steel | (54) (67) | Tool Steel | (25) (36) | (75) | Cast Iron | (33) (75) | ||

| ||||||||

Thin | 180~220 | 95~213 | Water | 242 | Ductile | 65~85 | ||

Tube | (54) (67) | Tool Steel | (29) (65) | Hardened | (75) | Austenitic | (20) (26) | |

|

|

|

| Tool Steel |

| Cast Iron |

| |

Aluminum | 220~534 | 203 | Stainless | 85 | Malleable | 321 | ||

Alloy | (67) (163) | Tool Steel | (62) | Steel | (26) | Cast Iron | (98) | |

Copper | 229~482 | 203~213 | CR Stainless | Plastics | 220 | |||

Alloy | (70) (147) | Tool Steel | (62) (65) | Steel | (26) (62) | (67) | ||

|

|

|

|

|

|

|

|

Figure 35. Dry cutting blade speed chart.

Chip Inspection Chart

The best method for choosing the cutting speed and feed rate for a cutting operation is to inspect the chips created by the cut. These chips will be indicators of what is commonly referred to as the "chip load". Refer to the chip inspection chart below to evaluate chip characteristics and determine whether to adjust feed rate/pressure, blade speed, or both.

Chip

Appearance

Chip

Description

Chip

Color

Blade Speed

Feed Rate/

Pressure

Other

Actions

| Thin & Curled | Silver | Good | Good |

|

|

|

|

|

|

|

| Hard, Thick & Short | Brown or Blue | Increase | Decrease |

|

|

|

|

|

|

|

| Hard, Strong & | Brown or Blue | Increase | Decrease |

|

| Thick |

| |||

|

|

|

|

| |

| Hard, Strong, | Silver or Light | Good | Decrease | Check Blade |

| Curled & Thick | Brown | Slightly | Pitch | |

|

| ||||

| Hard, Coiled & Thin | Silver | Increase | Decrease | Check Blade |

| Pitch | ||||

|

|

|

|

| |

| Straight & Thin | Silver | Good | Increase |

|

|

|

|

|

|

|

| Powdery | Silver | Decrease | Increase |

|

|

|

|

|

|

|

| Coiled, Tight & Thin | Silver | Good | Decrease | Check Blade |

| Pitch | ||||

|

|

|

|

|