For Machines Mfg. Since 8/09 | S E R V I C E | Model SB1018 |

Blade Guide Bearings

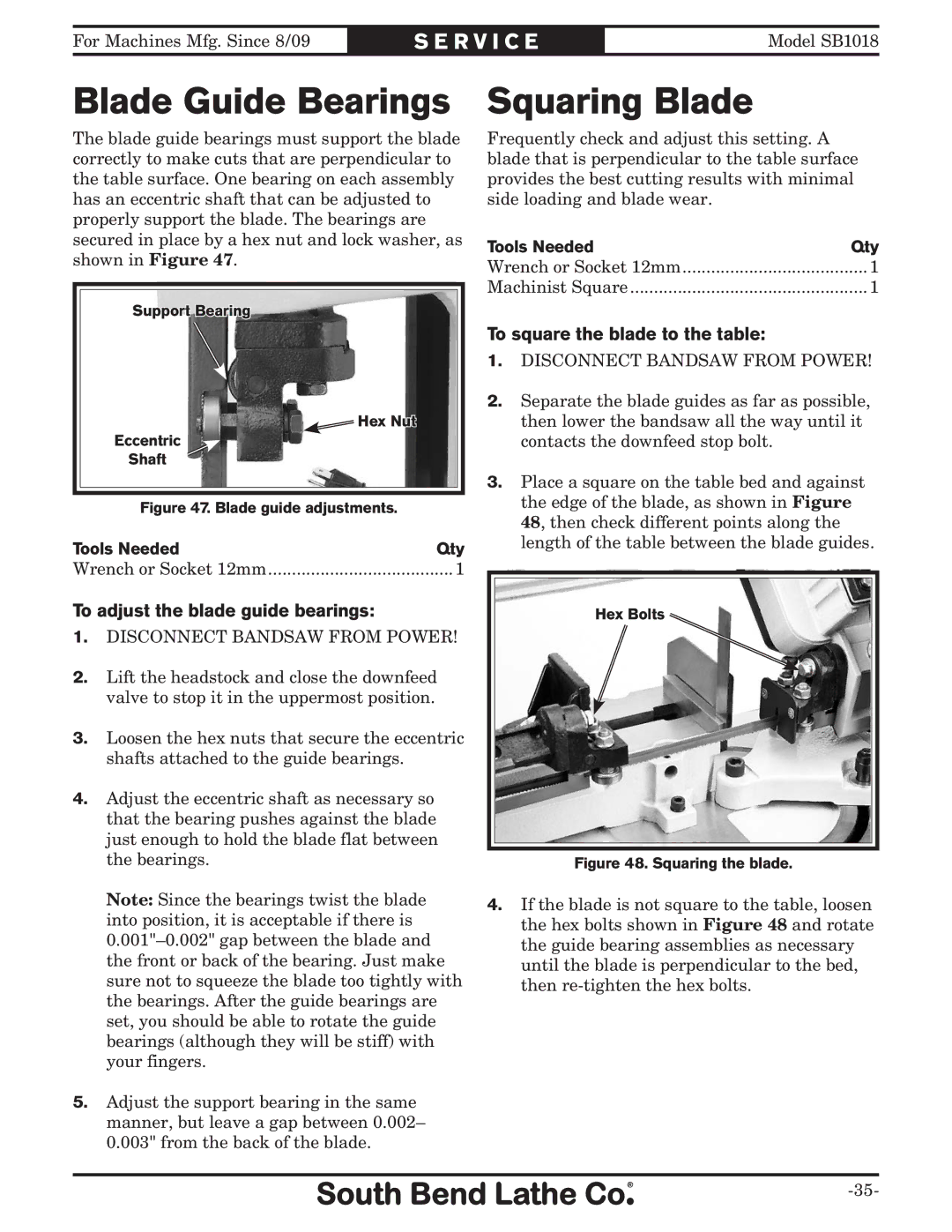

The blade guide bearings must support the blade correctly to make cuts that are perpendicular to the table surface. One bearing on each assembly has an eccentric shaft that can be adjusted to properly support the blade. The bearings are secured in place by a hex nut and lock washer, as shown in Figure 47.

Support Bearing

Hex Nut |

|

Eccentric |

|

Shaft |

|

Figure 47. Blade guide adjustments. |

|

Tools Needed | Qty |

Wrench or Socket 12mm | 1 |

To adjust the blade guide bearings:

1.DISCONNECT BANDSAW FROM POWER!

2.Lift the headstock and close the downfeed valve to stop it in the uppermost position.

3.Loosen the hex nuts that secure the eccentric shafts attached to the guide bearings.

4.Adjust the eccentric shaft as necessary so that the bearing pushes against the blade just enough to hold the blade flat between the bearings.

Note: Since the bearings twist the blade into position, it is acceptable if there is

5.Adjust the support bearing in the same manner, but leave a gap between 0.002– 0.003" from the back of the blade.

Squaring Blade

Frequently check and adjust this setting. A blade that is perpendicular to the table surface provides the best cutting results with minimal side loading and blade wear.

Tools Needed | Qty |

Wrench or Socket 12mm | ....................................... 1 |

Machinist Square | 1 |

To square the blade to the table:

1.DISCONNECT BANDSAW FROM POWER!

2.Separate the blade guides as far as possible, then lower the bandsaw all the way until it contacts the downfeed stop bolt.

3.Place a square on the table bed and against the edge of the blade, as shown in Figure 48, then check different points along the length of the table between the blade guides.

Hex Bolts

Figure 48. Squaring the blade.

4.If the blade is not square to the table, loosen the hex bolts shown in Figure 48 and rotate the guide bearing assemblies as necessary until the blade is perpendicular to the bed, then