For Machines Mfg. Since 8/09 | O P E R A T I O N | Model SB1040/SB1041 |

Blade Changes

! | Always disconnect power |

| to the machine when |

| changing blades. Failure |

| to do this may result in |

| serious personal injury. |

All saw blades are dangerous and may cause personal injury. To reduce the risk of being injured, wear leather gloves when handling saw blades.

To replace the blade:

1.DISCONNECT BANDSAW FROM POWER!

2.Open the upper and lower wheel doors, release tension on the blade, and move the blade guides away from the blade.

3.Put on heavy gloves, then slide the blade off the upper and lower wheels, around the blade post, and through the table slit.

4.Install a new blade in reverse order.

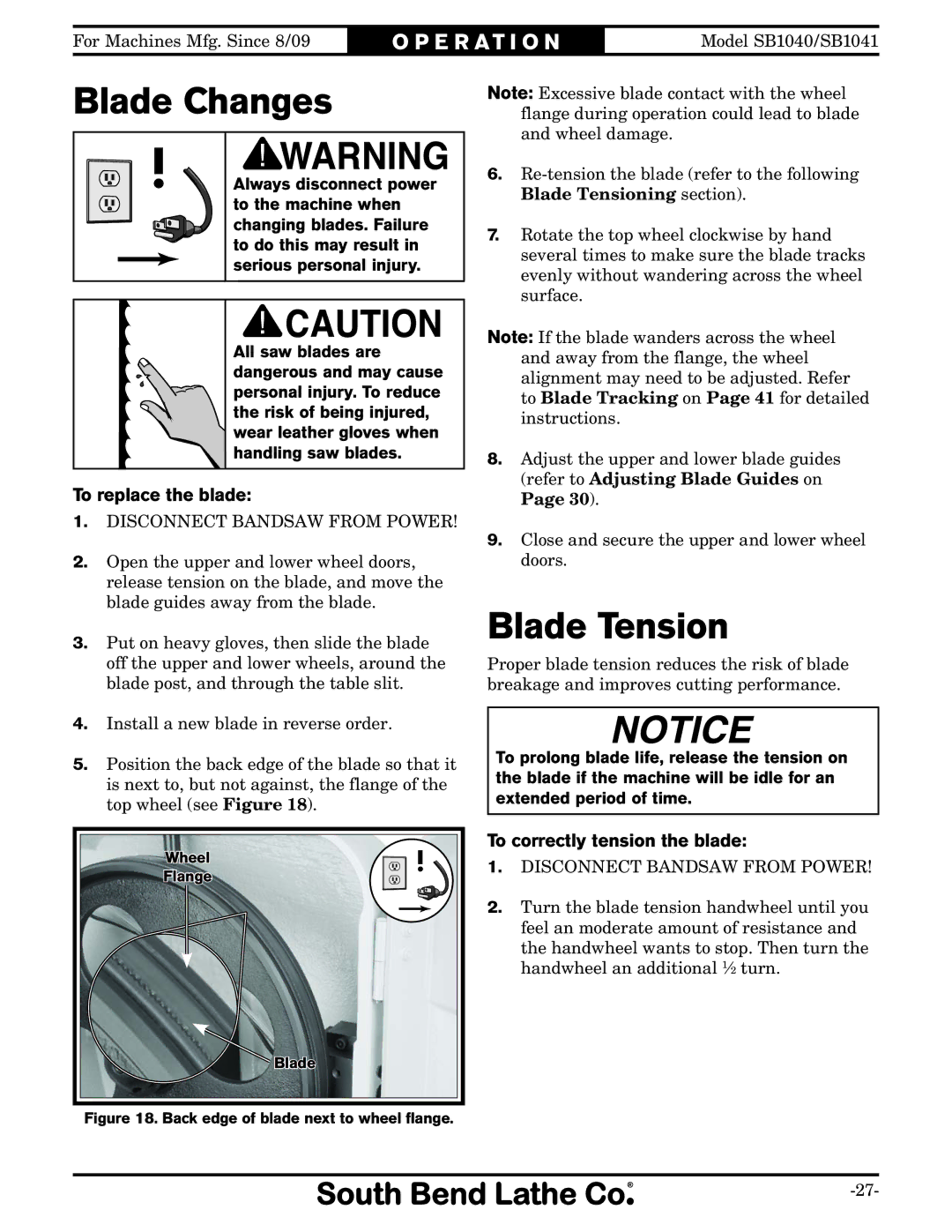

5.Position the back edge of the blade so that it is next to, but not against, the flange of the top wheel (see Figure 18).

Note: Excessive blade contact with the wheel flange during operation could lead to blade and wheel damage.

6.

7.Rotate the top wheel clockwise by hand several times to make sure the blade tracks evenly without wandering across the wheel surface.

Note: If the blade wanders across the wheel and away from the flange, the wheel alignment may need to be adjusted. Refer to Blade Tracking on Page 41 for detailed instructions.

8.Adjust the upper and lower blade guides (refer to Adjusting Blade Guides on Page 30).

9.Close and secure the upper and lower wheel doors.

Blade Tension

Proper blade tension reduces the risk of blade breakage and improves cutting performance.

To prolong blade life, release the tension on the blade if the machine will be idle for an extended period of time.

Wheel | ! |

| |

Flange |

|

![]() Blade

Blade

Figure 18. Back edge of blade next to wheel flange.

To correctly tension the blade:

1.DISCONNECT BANDSAW FROM POWER!

2.Turn the blade tension handwheel until you feel an moderate amount of resistance and the handwheel wants to stop. Then turn the handwheel an additional 1⁄2 turn.