Model SB1040/SB1041 | M A I N T E N A N C E | For Machines Mfg. Since 8/09 |

Lubrication

The bearings on your bandsaw are factory lubricated and sealed. Leave them alone unless they need to be replaced.

If the table becomes difficult to tilt, position it so that you can brush a thin coat of

When needed, brush a light coat of

! ![]() Grease

Grease

Figure 40. Upper wheel leadscrew lubrication.

Use

! Grease

Oil

Grease

Fitting

Behind

Plate

Grease Oil

Fitting

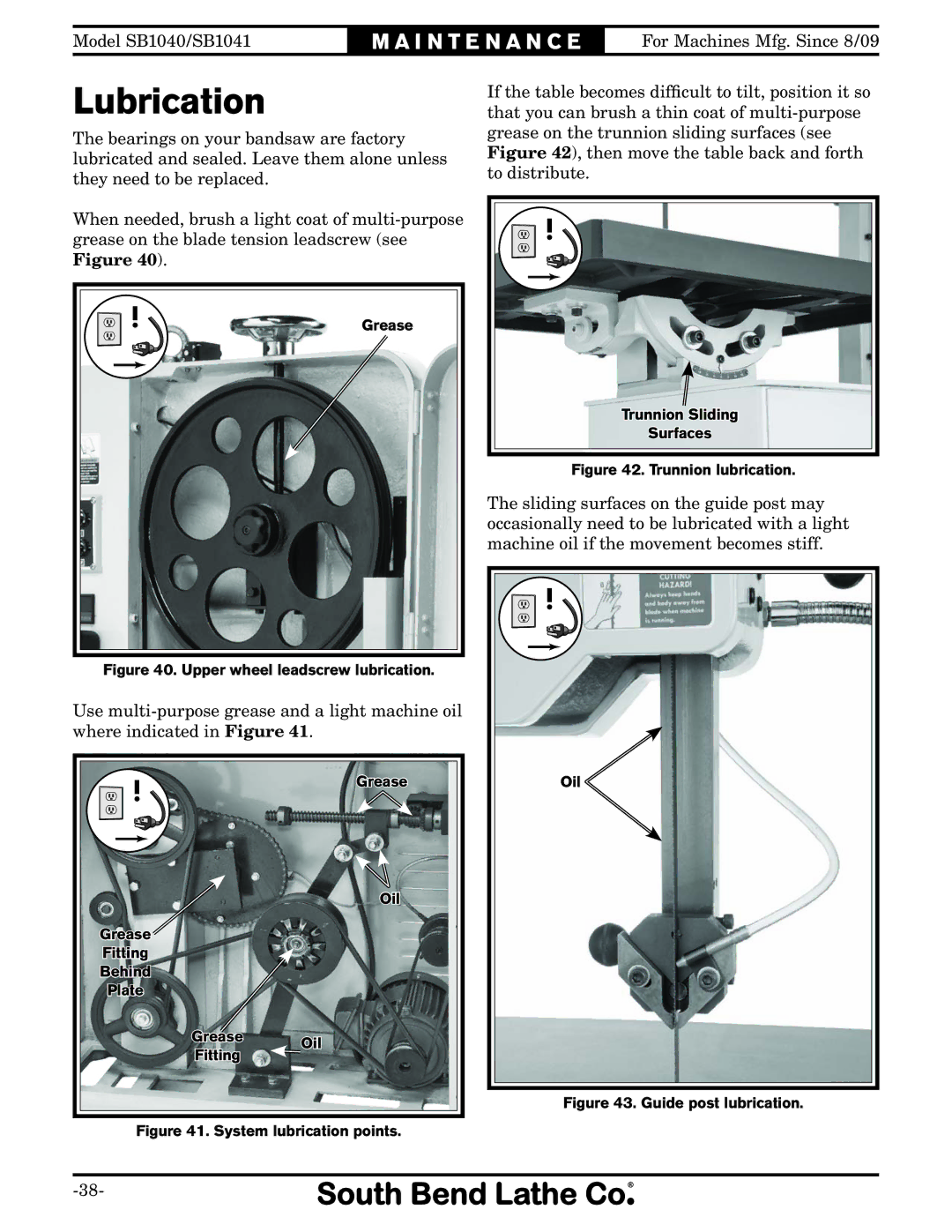

Figure 41. System lubrication points.

! |

Trunnion Sliding

Surfaces

Figure 42. Trunnion lubrication.

The sliding surfaces on the guide post may occasionally need to be lubricated with a light machine oil if the movement becomes stiff.

! |

Oil