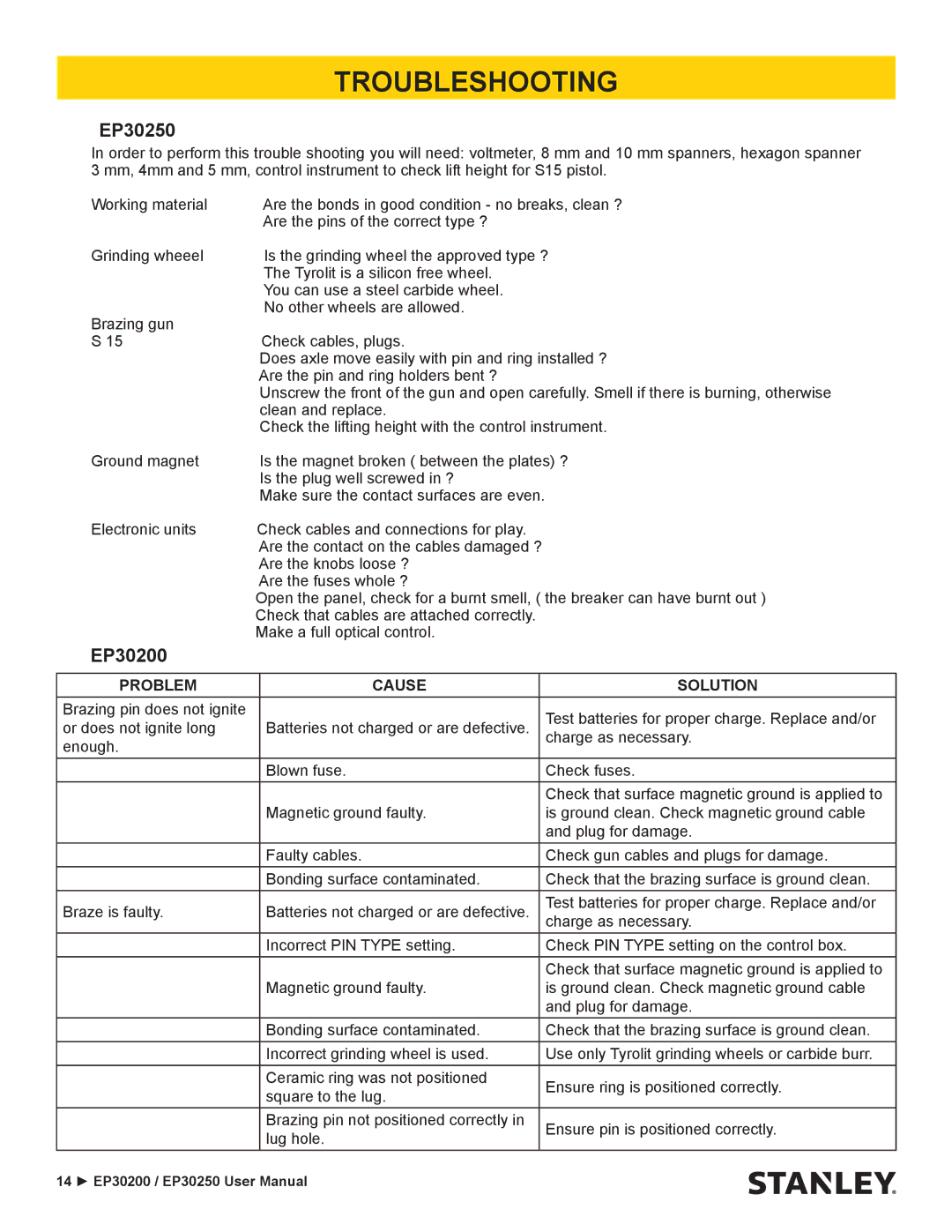

TROUBLESHOOTING

EP30250

In order to perform this trouble shooting you will need: voltmeter, 8 mm and 10 mm spanners, hexagon spanner 3 mm, 4mm and 5 mm, control instrument to check lift height for S15 pistol.

Working material |

| Are the bonds in good condition - no breaks, clean ? | ||

|

| Are the pins of the correct type ? |

| |

Grinding wheeel |

| Is the grinding wheel the approved type ? | ||

|

| The Tyrolit is a silicon free wheel. |

| |

|

| You can use a steel carbide wheel. |

| |

Brazing gun |

| No other wheels are allowed. |

| |

|

|

|

| |

S 15 |

| Check cables, plugs. |

| |

|

| Does axle move easily with pin and ring installed ? | ||

| Are the pin and ring holders bent ? |

| ||

|

| Unscrew the front of the gun and open carefully. Smell if there is burning, otherwise | ||

|

| clean and replace. |

| |

|

| Check the lifting height with the control instrument. | ||

Ground magnet |

| Is the magnet broken ( between the plates) ? | ||

|

| Is the plug well screwed in ? |

| |

|

| Make sure the contact surfaces are even. |

| |

Electronic units | Check cables and connections for play. |

| ||

| Are the contact on the cables damaged ? |

| ||

| Are the knobs loose ? |

| ||

| Are the fuses whole ? |

| ||

| Open the panel, check for a burnt smell, ( the breaker can have burnt out ) | |||

| Check that cables are attached correctly. |

| ||

| Make a full optical control. |

| ||

EP30200 |

|

|

|

|

|

|

|

|

|

PROBLEM |

| CAUSE |

| SOLUTION |

Brazing pin does not ignite |

|

|

| Test batteries for proper charge. Replace and/or |

or does not ignite long |

| Batteries not charged or are defective. |

| |

|

| charge as necessary. | ||

enough. |

|

|

|

|

|

| Blown fuse. |

| Check fuses. |

|

|

|

| Check that surface magnetic ground is applied to |

|

| Magnetic ground faulty. |

| is ground clean. Check magnetic ground cable |

|

|

|

| and plug for damage. |

|

| Faulty cables. |

| Check gun cables and plugs for damage. |

|

| Bonding surface contaminated. |

| Check that the brazing surface is ground clean. |

Braze is faulty. |

| Batteries not charged or are defective. |

| Test batteries for proper charge. Replace and/or |

|

| charge as necessary. | ||

|

| Incorrect PIN TYPE setting. |

| Check PIN TYPE setting on the control box. |

|

|

|

| Check that surface magnetic ground is applied to |

|

| Magnetic ground faulty. |

| is ground clean. Check magnetic ground cable |

|

|

|

| and plug for damage. |

|

| Bonding surface contaminated. |

| Check that the brazing surface is ground clean. |

|

| Incorrect grinding wheel is used. |

| Use only Tyrolit grinding wheels or carbide burr. |

|

| Ceramic ring was not positioned |

| Ensure ring is positioned correctly. |

|

| square to the lug. |

| |

|

|

|

| |

|

| Brazing pin not positioned correctly in |

| Ensure pin is positioned correctly. |

|

| lug hole. |

| |

|

|

|

| |

14 ► EP30200 / EP30250 User Manual |

| |||