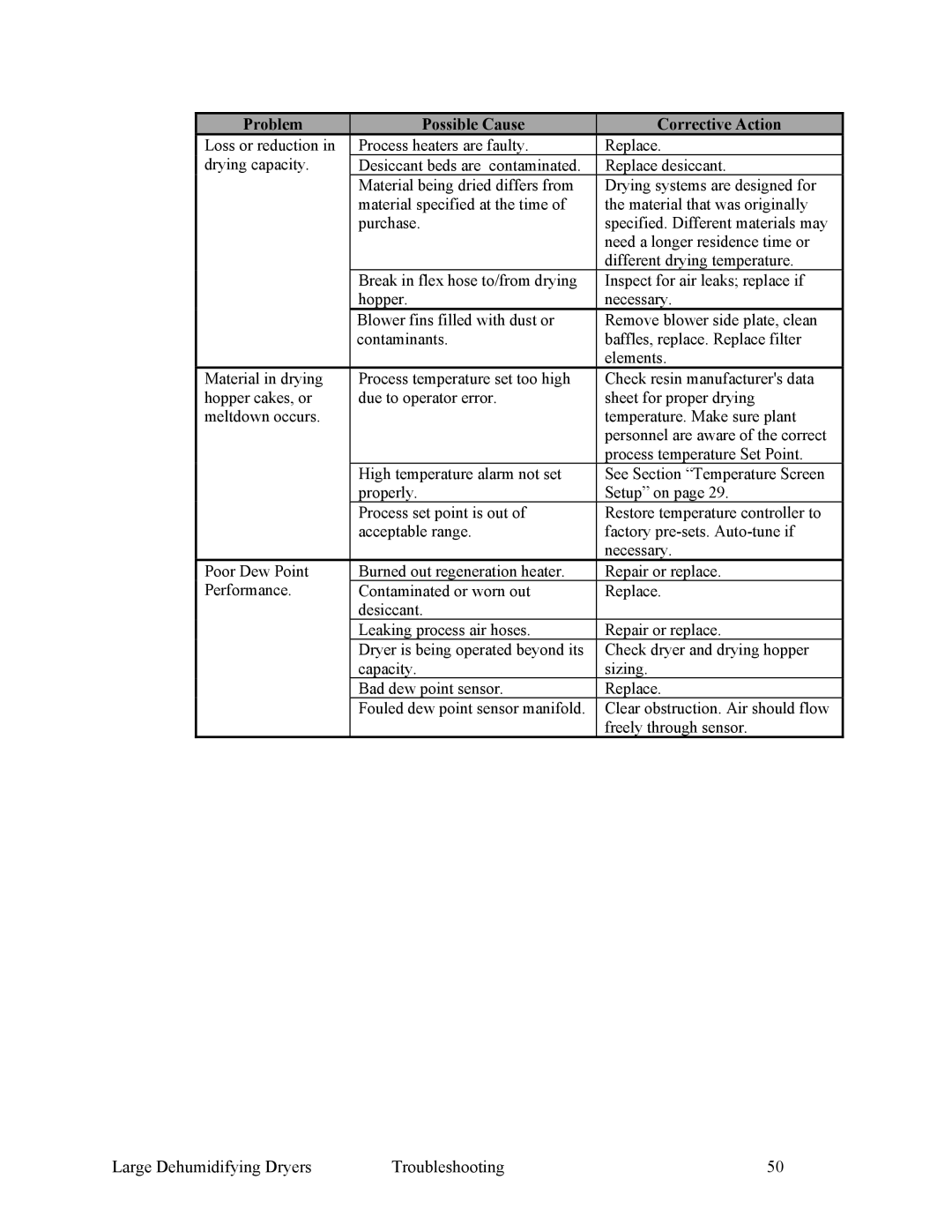

Problem | Possible Cause | Corrective Action |

Loss or reduction in | Process heaters are faulty. | Replace. |

drying capacity. | Desiccant beds are contaminated. | Replace desiccant. |

| Material being dried differs from | Drying systems are designed for |

| material specified at the time of | the material that was originally |

| purchase. | specified. Different materials may |

|

| need a longer residence time or |

|

| different drying temperature. |

| Break in flex hose to/from drying | Inspect for air leaks; replace if |

| hopper. | necessary. |

| Blower fins filled with dust or | Remove blower side plate, clean |

| contaminants. | baffles, replace. Replace filter |

|

| elements. |

Material in drying | Process temperature set too high | Check resin manufacturer's data |

hopper cakes, or | due to operator error. | sheet for proper drying |

meltdown occurs. |

| temperature. Make sure plant |

|

| personnel are aware of the correct |

|

| process temperature Set Point. |

| High temperature alarm not set | See Section “Temperature Screen |

| properly. | Setup” on page 29. |

| Process set point is out of | Restore temperature controller to |

| acceptable range. | factory |

|

| necessary. |

Poor Dew Point | Burned out regeneration heater. | Repair or replace. |

Performance. | Contaminated or worn out | Replace. |

| desiccant. |

|

| Leaking process air hoses. | Repair or replace. |

| Dryer is being operated beyond its | Check dryer and drying hopper |

| capacity. | sizing. |

| Bad dew point sensor. | Replace. |

| Fouled dew point sensor manifold. | Clear obstruction. Air should flow |

|

| freely through sensor. |

Large Dehumidifying Dryers | Troubleshooting | 50 |