;Make sure all electrical connections are tight.

3-4 Making Gas Line Connections (Gas-Fired Models Only)

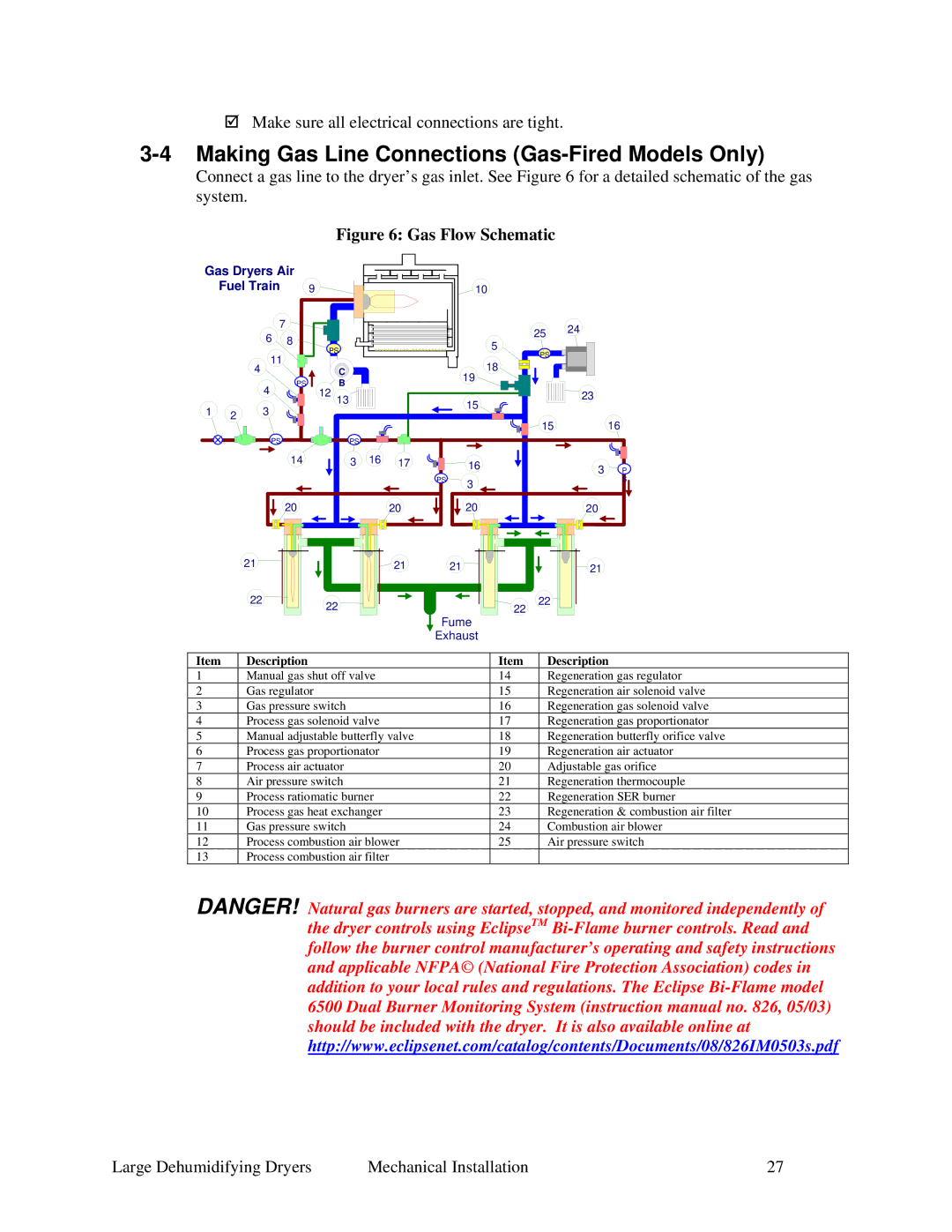

Connect a gas line to the dryer’s gas inlet. See Figure 6 for a detailed schematic of the gas system.

Figure 6: Gas Flow Schematic

Gas Dryers Air |

|

|

|

|

|

|

|

|

| |||

| Fuel Train | 9 |

|

|

|

|

| 10 |

|

|

| |

|

| 7 |

|

|

|

|

|

| 25 | 24 |

| |

|

| 6 | 8 |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| 5 |

|

| |||

|

|

|

|

|

|

|

|

|

| |||

|

| 11 | PS |

|

|

|

| PS |

|

| ||

|

|

|

|

|

|

|

|

|

|

| ||

| 4 |

|

| C |

|

|

| 18 |

|

|

| |

|

| 4 | PS |

| B |

|

|

| 19 |

|

|

|

|

| 12 | 13 |

|

|

| 15 |

| 23 |

| ||

1 |

| 3 |

|

|

|

|

|

|

| |||

2 |

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

| 15 |

| 16 | |||

|

|

|

|

|

|

|

|

|

|

| ||

|

| PS |

|

| PS |

|

|

|

|

|

|

|

|

|

| 14 |

| 3 | 16 | 17 |

| 16 |

| 3 | P |

|

|

|

|

|

|

|

| PS | 3 |

|

| S |

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

| 20 |

|

|

| 20 |

| 20 |

| 20 |

|

| 21 |

|

|

|

|

| 21 | 21 |

|

| 21 |

|

| 22 |

| 22 |

|

|

|

| 22 | 22 |

|

| |

|

|

|

|

|

|

|

|

|

| |||

Fume

Exhaust

Item | Description | Item | Description |

1 | Manual gas shut off valve | 14 | Regeneration gas regulator |

2 | Gas regulator | 15 | Regeneration air solenoid valve |

3 | Gas pressure switch | 16 | Regeneration gas solenoid valve |

4 | Process gas solenoid valve | 17 | Regeneration gas proportionator |

5 | Manual adjustable butterfly valve | 18 | Regeneration butterfly orifice valve |

6 | Process gas proportionator | 19 | Regeneration air actuator |

7 | Process air actuator | 20 | Adjustable gas orifice |

8 | Air pressure switch | 21 | Regeneration thermocouple |

9 | Process ratiomatic burner | 22 | Regeneration SER burner |

10 | Process gas heat exchanger | 23 | Regeneration & combustion air filter |

11 | Gas pressure switch | 24 | Combustion air blower |

12 | Process combustion air blower | 25 | Air pressure switch |

13 | Process combustion air filter |

|

|

DANGER! Natural gas burners are started, stopped, and monitored independently of the dryer controls using EclipseTM

Large Dehumidifying Dryers | Mechanical Installation | 27 |