By pressing the LOW TEMP or HIGH TEMP alarm buttons, the operator can enter the desired values to enable the alarm to go off at a specific deviation from setpoint (on the high or low side).

When these settings have been made, the operator now has a choice of returning to the DRYER MENU or entering the MAIN MENU screen.

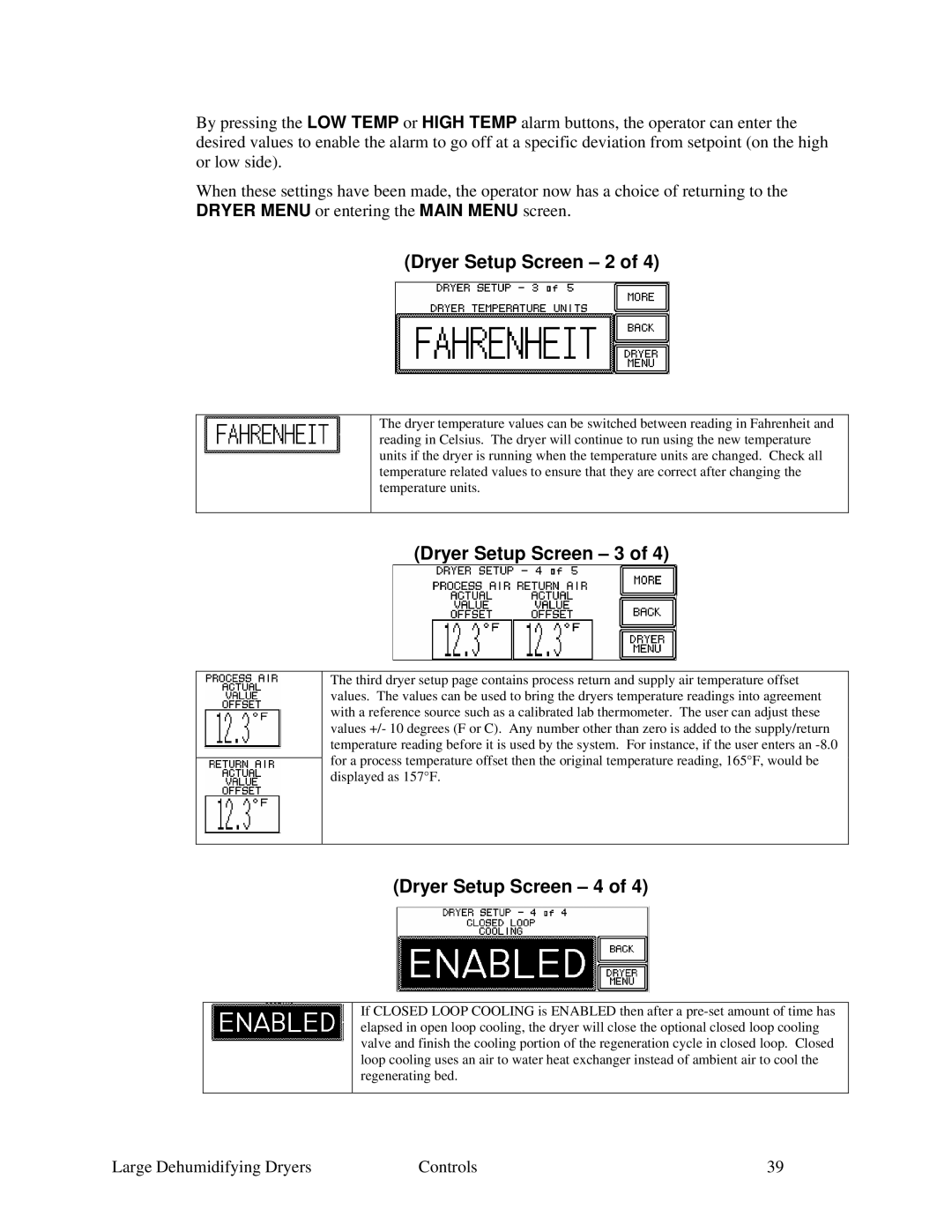

(Dryer Setup Screen – 2 of 4)

The dryer temperature values can be switched between reading in Fahrenheit and reading in Celsius. The dryer will continue to run using the new temperature units if the dryer is running when the temperature units are changed. Check all temperature related values to ensure that they are correct after changing the temperature units.

(Dryer Setup Screen – 3 of 4)

The third dryer setup page contains process return and supply air temperature offset values. The values can be used to bring the dryers temperature readings into agreement with a reference source such as a calibrated lab thermometer. The user can adjust these values +/- 10 degrees (F or C). Any number other than zero is added to the supply/return temperature reading before it is used by the system. For instance, if the user enters an

(Dryer Setup Screen – 4 of 4)

If CLOSED LOOP COOLING is ENABLED then after a

Large Dehumidifying Dryers | Controls | 39 |