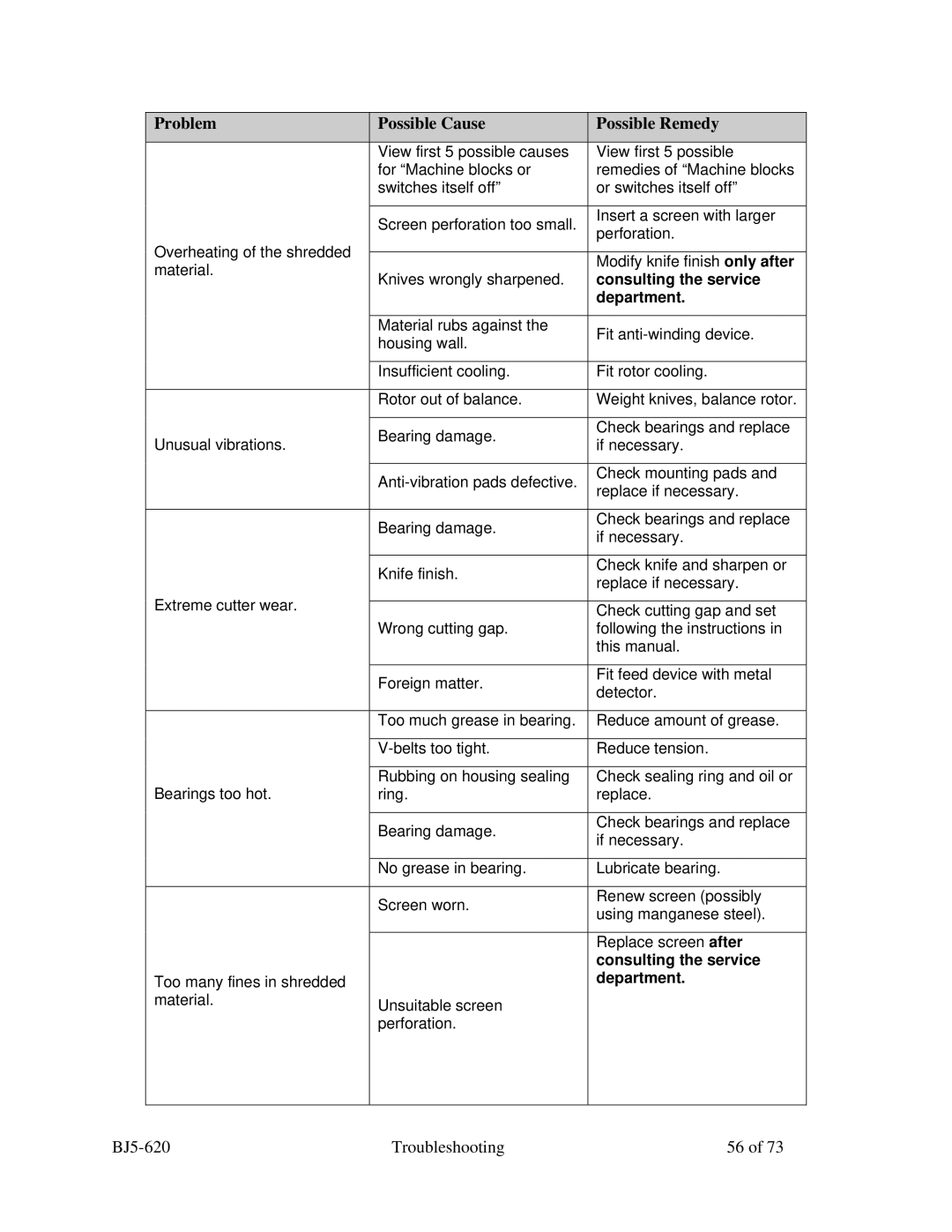

| Problem | Possible Cause | Possible Remedy |

|

|

|

|

|

| View first 5 possible causes | View first 5 possible |

|

| for “Machine blocks or | remedies of “Machine blocks |

|

| switches itself off” | or switches itself off” |

|

|

|

|

|

| Screen perforation too small. | Insert a screen with larger |

|

| perforation. | |

| Overheating of the shredded |

| |

|

|

| |

|

| Modify knife finish only after | |

| material. | Knives wrongly sharpened. | |

| consulting the service | ||

|

| ||

|

|

| department. |

|

|

|

|

|

| Material rubs against the | Fit |

|

| housing wall. | |

|

|

| |

|

|

|

|

|

| Insufficient cooling. | Fit rotor cooling. |

|

|

|

|

|

| Rotor out of balance. | Weight knives, balance rotor. |

|

|

|

|

| Unusual vibrations. | Bearing damage. | Check bearings and replace |

| if necessary. | ||

|

| ||

|

|

|

|

|

| Check mounting pads and | |

|

| replace if necessary. | |

|

|

| |

|

|

|

|

|

| Bearing damage. | Check bearings and replace |

|

| if necessary. | |

|

|

| |

|

|

|

|

|

| Knife finish. | Check knife and sharpen or |

|

| replace if necessary. | |

|

|

| |

| Extreme cutter wear. |

|

|

| Wrong cutting gap. | Check cutting gap and set | |

|

| following the instructions in | |

|

|

| this manual. |

|

|

|

|

|

| Foreign matter. | Fit feed device with metal |

|

| detector. | |

|

|

| |

|

|

|

|

|

| Too much grease in bearing. | Reduce amount of grease. |

|

|

|

|

|

| Reduce tension. | |

|

|

|

|

| Bearings too hot. | Rubbing on housing sealing | Check sealing ring and oil or |

| ring. | replace. | |

|

|

|

|

|

| Bearing damage. | Check bearings and replace |

|

| if necessary. | |

|

|

| |

|

|

|

|

|

| No grease in bearing. | Lubricate bearing. |

|

|

|

|

|

| Screen worn. | Renew screen (possibly |

|

| using manganese steel). | |

|

|

| |

|

|

|

|

|

|

| Replace screen after |

|

|

| consulting the service |

| Too many fines in shredded |

| department. |

| material. | Unsuitable screen |

|

|

| perforation. |

|

|

|

|

|

Troubleshooting | 56 of 73 | ||

Page 56

Image 56