8.Pivot the screen support into the working position and fasten using mounting screws.

9.Close the machine door.

10.Shredder can be started again.

(Please refer to image from “Emptying the Screen”.)

V-Belts

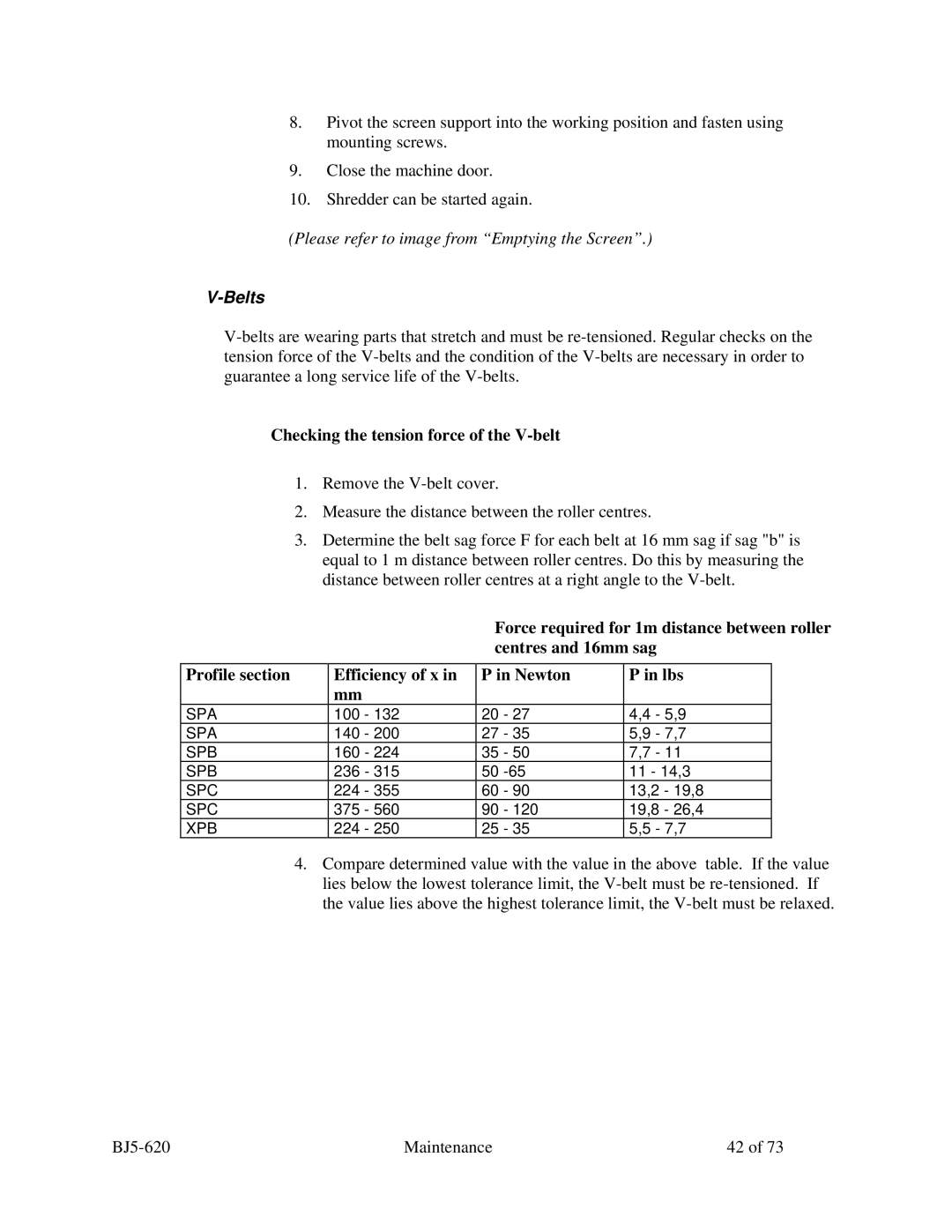

Checking the tension force of the V-belt

1.Remove the

2.Measure the distance between the roller centres.

3.Determine the belt sag force F for each belt at 16 mm sag if sag "b" is equal to 1 m distance between roller centres. Do this by measuring the distance between roller centres at a right angle to the

|

| Force required for 1m distance between roller | ||||

|

| centres and 16mm sag | ||||

|

|

|

|

| ||

Profile section | Efficiency of x in | P in Newton | P in lbs |

| ||

| mm |

|

|

|

|

|

SPA | 100 - 132 | 20 | - 27 | 4,4 | - 5,9 |

|

SPA | 140 - 200 | 27 | - 35 | 5,9 | - 7,7 |

|

SPB | 160 - 224 | 35 | - 50 | 7,7 | - 11 |

|

SPB | 236 - 315 | 50 | 11 - 14,3 |

| ||

SPC | 224 - 355 | 60 | - 90 | 13,2 - 19,8 |

| |

SPC | 375 - 560 | 90 | - 120 | 19,8 - 26,4 |

| |

XPB | 224 - 250 | 25 | - 35 | 5,5 | - 7,7 |

|

4.Compare determined value with the value in the above table. If the value lies below the lowest tolerance limit, the

Maintenance | 42 of 73 |