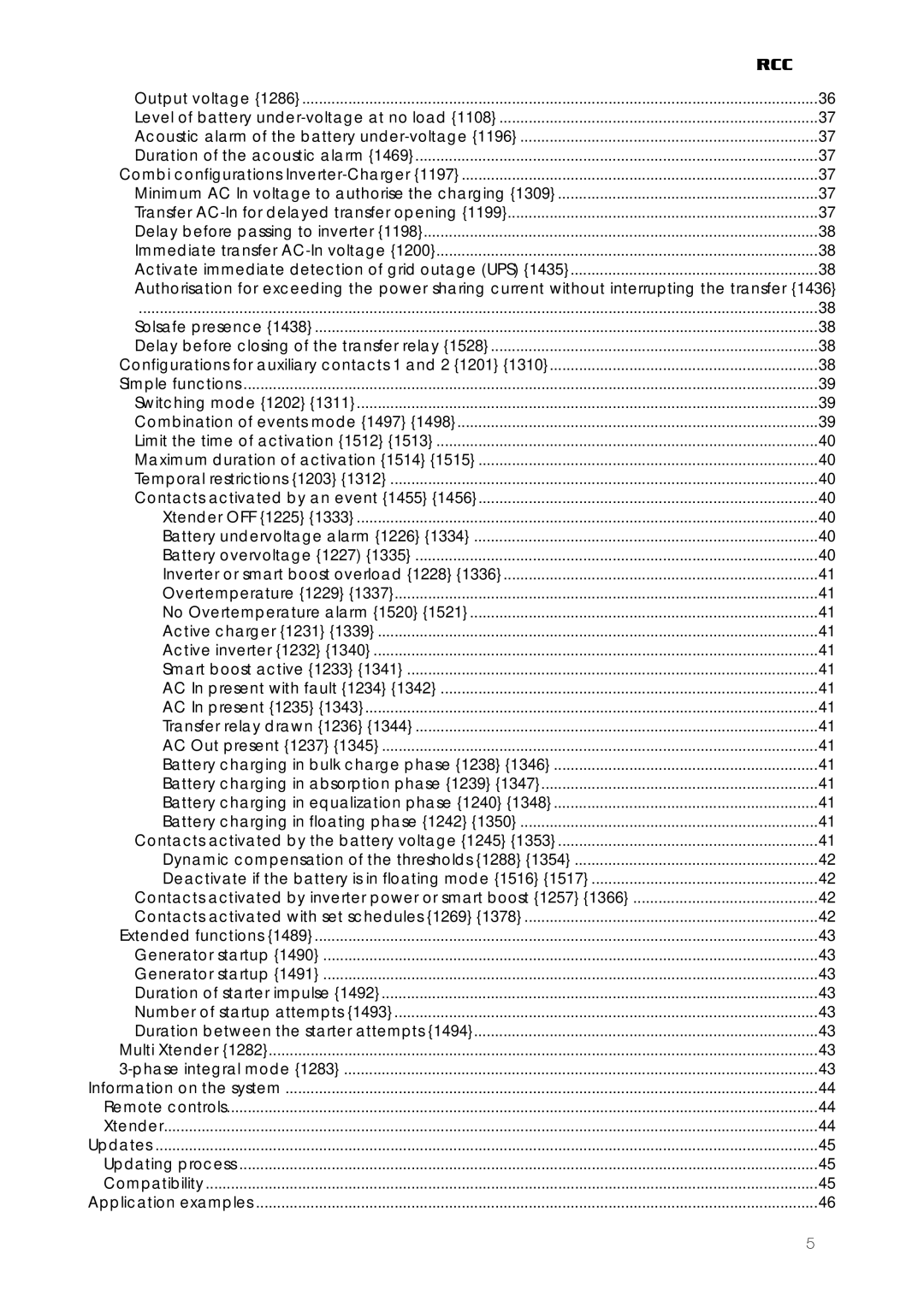

RCC-03, RCC-02 specifications

Studer Innotec, a renowned Swiss company in the field of power electronics, has made significant strides with its range of battery management systems, particularly the RCC-02 and RCC-03 models. These units are renowned for their cutting-edge technologies, impressive features, and superior performance in managing energy systems for both off-grid and hybrid applications.The RCC-02 and RCC-03 Remote Control Displays provide end-users with an intuitive interface to monitor and control their energy systems seamlessly. With a clear and easy-to-read display, these units offer real-time data, allowing users to view essential information such as battery voltage, current, and state of charge. This vital information empowers users to make informed decisions regarding energy consumption and system management.

One of the standout features of the RCC-02 and RCC-03 models is their compatibility with a wide range of Studer Innotec products, including inverters and battery chargers. This versatility ensures seamless integration into existing systems, making it an ideal choice for both new installations and upgrades of existing systems.

Both models incorporate advanced communication technologies such as RS-232 and CAN-bus, allowing for easy data logging and system monitoring. This connectivity not only ensures that the user has access to real-time data but also enables remote monitoring and diagnostics, significantly enhancing the overall user experience.

Another characteristic that sets the RCC-02 and RCC-03 apart is their robust design. These units are engineered to withstand the harsh conditions often found in off-grid environments, ensuring reliability and durability over an extended lifespan. The thoughtful design also includes user-friendly controls, making it easy to configure settings and manage system parameters for a wide array of applications.

Energy efficiency is paramount in today's energy-conscious world, and the RCC-02 and RCC-03 are designed to optimize battery usage. By providing timely information about battery status and energy flow, these units assist users in maximizing the lifespan of their batteries and ensuring that their energy resources are used effectively.

In summary, Studer Innotec’s RCC-02 and RCC-03 Remote Control Displays are essential components for anyone looking to harness the power of reliable battery management systems. With their advanced technologies, user-friendly interfaces, and robust construction, they represent the cutting edge of energy management in both off-grid and hybrid applications. Whether for residential, commercial, or industrial use, these units deliver efficiency, reliability, and peace of mind to users.