Page 4

conversion can be done quite simply as follows (see Figures 2 and 3):

1.Remove the vent exhaust grille by removing the four screws which retain it. The grille, its gasket, and the screws may be discarded.

2.Place the vent collar gasket on the top of the heater aligning its center hole and screw holes with those in the top of the heater.

3.Place the vent collar over the gasket and fasten it in place with the screws and lockwashers provided. Be sure that all components are properly aligned. Screws must be tightened enough to assure a sealed joint without deforming the vent collar.

2G-2. Combustion Air Requirements for One-Pipe Installation

| Required net free area in square inches (sq. cm) | |

| for each of 2 openings - one near ceiling and | |

Model | one near floor | |

|

| |

|

|

|

| Directly Through an | Through |

| Exterior Wall | Horizontal Ducts |

|

|

|

220 | 55 (355) | 110 (710) |

|

|

|

350 | 88 (570) | 175 (1130) |

|

|

|

Table 2. Required Net Free Area of Openings for Combustion and Ventilation Air.

Note that the numbers indicate the net free area

—after allowing for the blockage of grille bars, etc. See applicable local codes and the

See Section

![]() WARNING

WARNING

Do not store any chemicals, cleaners, or other corrosive material near combustion air openings or in the room. Avoid location of dryer vents in the vicinity of combustion air openings. Failure to prevent corrosive materials from mixing with combustion air can result in reduced heater life and unsafe heater operation.

2G-3. Two-Pipe Installation (Direct Vent)

This section specifies installation requirements for combustion air and vent piping for “two pipe” installations. A

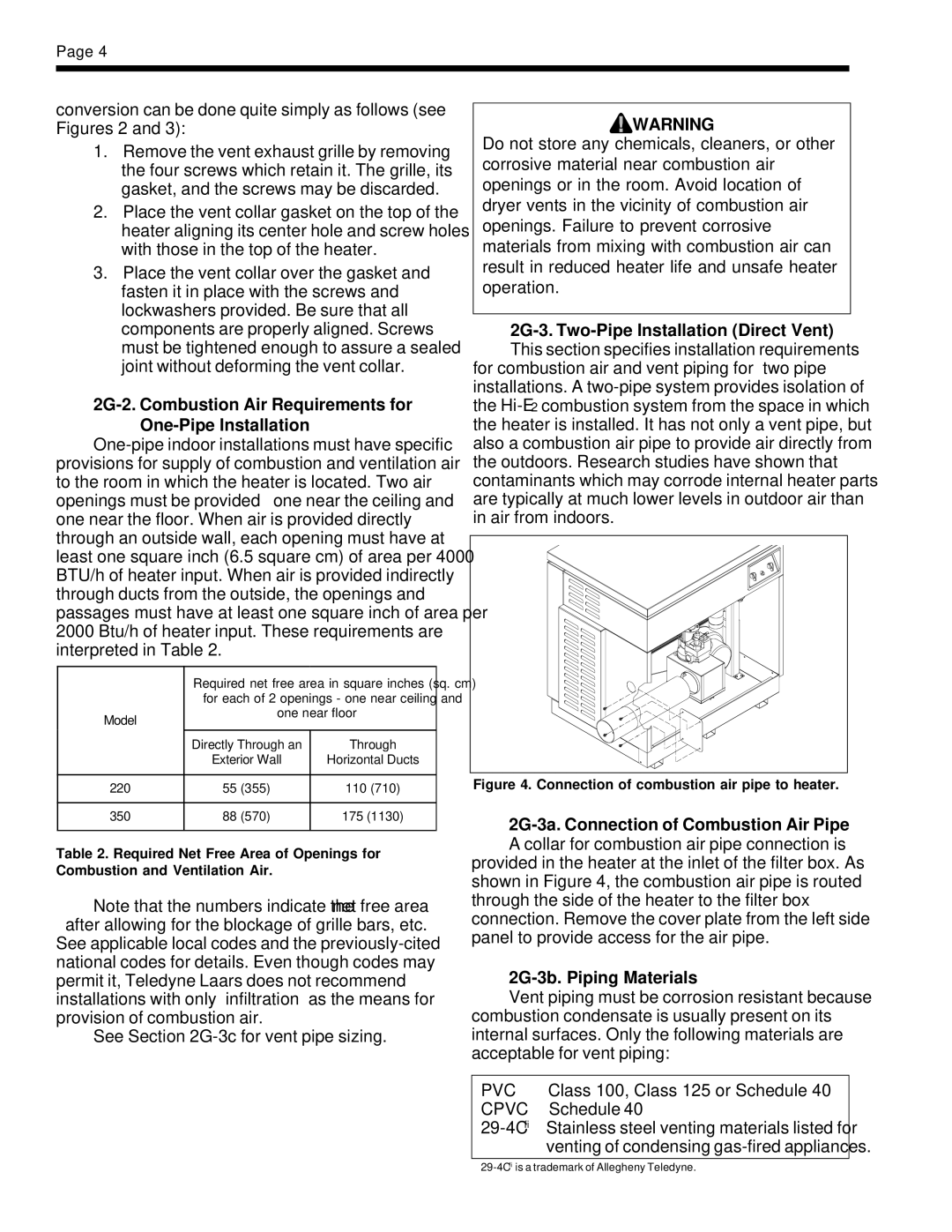

Figure 4. Connection of combustion air pipe to heater.

2G-3a. Connection of Combustion Air Pipe

A collar for combustion air pipe connection is provided in the heater at the inlet of the filter box. As shown in Figure 4, the combustion air pipe is routed through the side of the heater to the filter box connection. Remove the cover plate from the left side panel to provide access for the air pipe.

2G-3b. Piping Materials

Vent piping must be corrosion resistant because combustion condensate is usually present on its internal surfaces. Only the following materials are acceptable for vent piping:

PVC | Class 100, Class 125 or Schedule 40 |

CPVC | Schedule 40 |

Stainless steel venting materials listed for | |

| venting of condensing |