3 Operation | Model | |

|

|

|

|

|

|

|

|

|

NOTE: This procedure is more critical on the

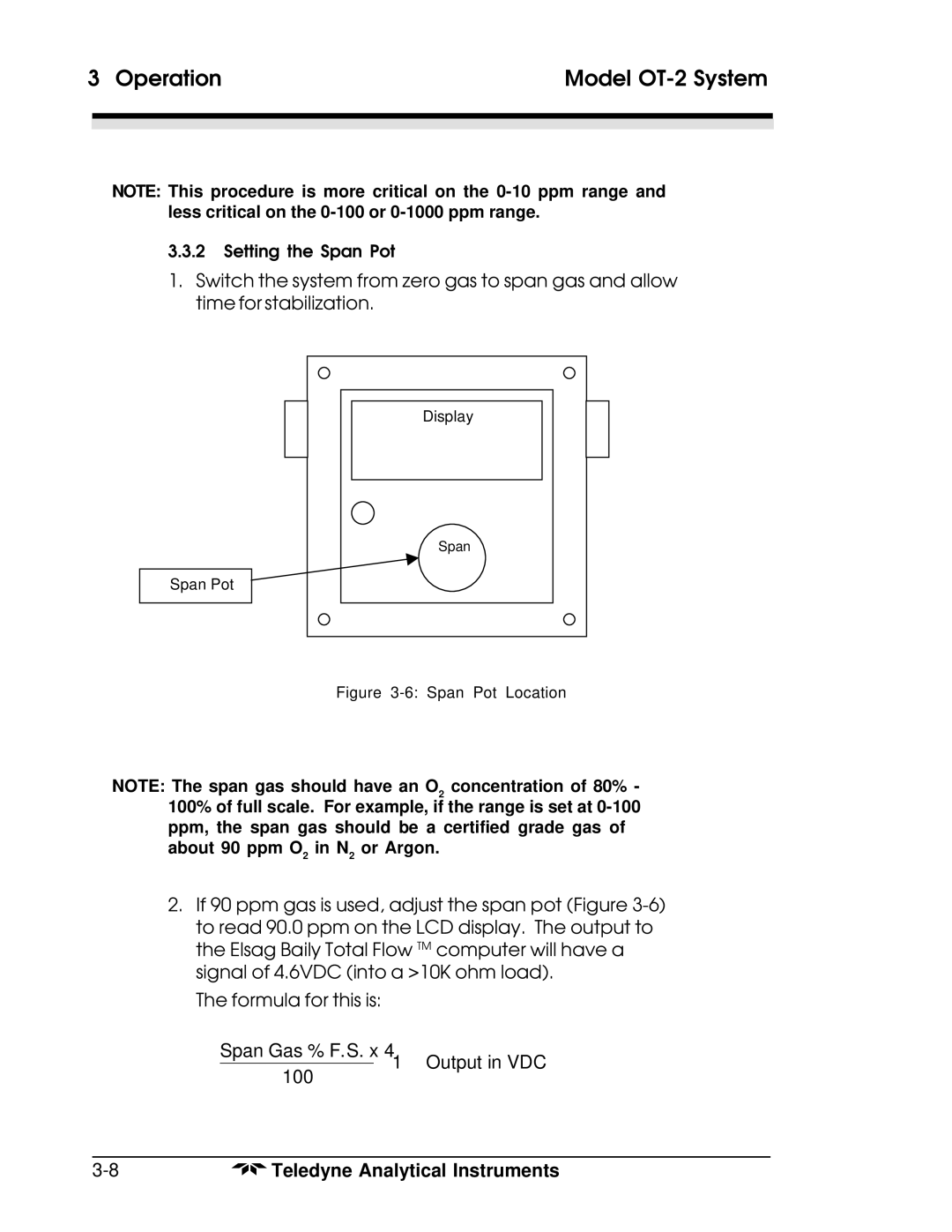

3.3.2Setting the Span Pot

1.Switch the system from zero gas to span gas and allow time for stabilization.

Span Pot

Display |

Span |

Figure 3-6: Span Pot Location

NOTE: The span gas should have an O2 concentration of 80% - 100% of full scale. For example, if the range is set at

2.If 90 ppm gas is used, adjust the span pot (Figure

The formula for this is:

Span Gas % F.S. x 4 + =

1 Output in VDC

100

Teledyne Analytical Instruments |