Contents

MODELS

OR LP GAS PROPANE CDX3-75N CDX3-100N CDX3-125N

TWO STAGE CONDENSING GAS FURNACE

I. SAFETY INFORMATION

This and the previous page contain reproductions of the various warning and instruction labels placed on the Thermo Pride Two Stage Condensing Gas Furnaces. Please read and comply with the contents of these labels

1.A windows be opened

The CHX3/CDX3 furnace models are sealed combustion design, which does not require an air shutter adjustment air shutters are not used for proper flame characteristics. Burner box access cover must always be secured with all screws in place and tightened before operating furnace

INDEX

SECTION

BEGINNING PAGE

II. FURNACE SPECIFICATIONS CHX3 SERIES

CDX3 SERIES

INSTALLATION PARTS PACKAGES - CHX3-75

INSTALLATION PARTS PACKAGES - CDX3-75

Grounding instructions

III. GENERAL INSTALLATION

B. FURNACE LOCATION

B1. CDX3 HORIZONTAL APPLICATION

Page

PVC Pipe Designation

Maximum Quantity of Elbows

E.Direct Venting Through a Sidewall

Outside Combustion Air Intake RH view

c.The vent terminal shall not be located

Page

E1. Single-PipeSidewall Venting Option

5.Optional Direct Vent Terminations

Install these optional kits according to the instructions provided with each kit. The location and clearance requirements are identical to those of the standard vent terminations described in this manual

1.Figures 6B, 7, and 8 follow depicting typical exhaust vent and air intake connections for the furnace model series CHX3 and the CDX3, respectively, as well as a list of required parts to correctly install each system

Page

Applications

Figure 9 Typical Internal Vent

Piping Arrangement for the

Furnace Model Series CHX3

3. Connecting The Combustion Air Intake Piping

I.CONDENSATE DRAIN LINE AND TRAP ASSEMBLY

Figure 14. TRAP ASSEMBLY MOUNTED ON CHX3

Figure 15. TRAP ASSEMBLY MOUNTED ON CDX3

2.Determine on which side of furnace the condensate disposal line is to be run NOTICE On CHX3/CDX3’s this must be the same side as the flue outlet or bottom of unit. Attach the condensate trap to the furnace casing using the #8x3/4” sheet metal screws provided in the parts package. Pilot holes are provided on both sides of the casing for mounting

J. GENERAL GAS PIPING

J1. REQUIREMENTS AND SIZING OF DUCT WORK

Figure 18A

TABLE 2A

K. FILTERS 1. CHX3 MODELS HIGHBOYS

2. CDX3 MODELS COUNTERFLOWS

Page

L. WIRING

Table 4A

Options

S7 DIP Switch

Switch Settings

Time

2-StageBlower Settings from factory Table 4C

IV. STARTING THE UNIT A. SEQUENCE OF OPERATIONS

IF NOT

IF THERMOSTAT W2 CONTACTS ARE CLOSED OTHERWISE

B. INITIAL START UP

OPERATING INSTRUCTIONS

A.Burner manifold pressure with a pressure gauge

C. Measuring And Adjusting Heat Input Rate

Observe the following precautions when measuring

B.Gas flowrate by clocking gas meter

NOTICE A U-tubemanometer, measuring pressure in inches of water column, is recommended for all gas pressure measurements. However, an aneroid pressure gauge, in good working condition, capable of reading pressure changes of 0.05 in. W.G., or less, that was recently calibrated within the last year, is a satisfactory alternate. These two 2 devices will be considered as equivalent and interchangeable. Either device is referred to below as a “pressure gauge”

Heat input rate in BTUH =

Page

21.Go to Checkout Procedure below

Checking The Burner Flame

Checkout Procedure

TABLE 6 - CONVERTING GAS FLOW RATE

D. FURNACE CHECKOUT PROCEDURE

V. INSTALLERS INSTRUCTIONS TO USER

Figure VI. TROUBLESHOOTING

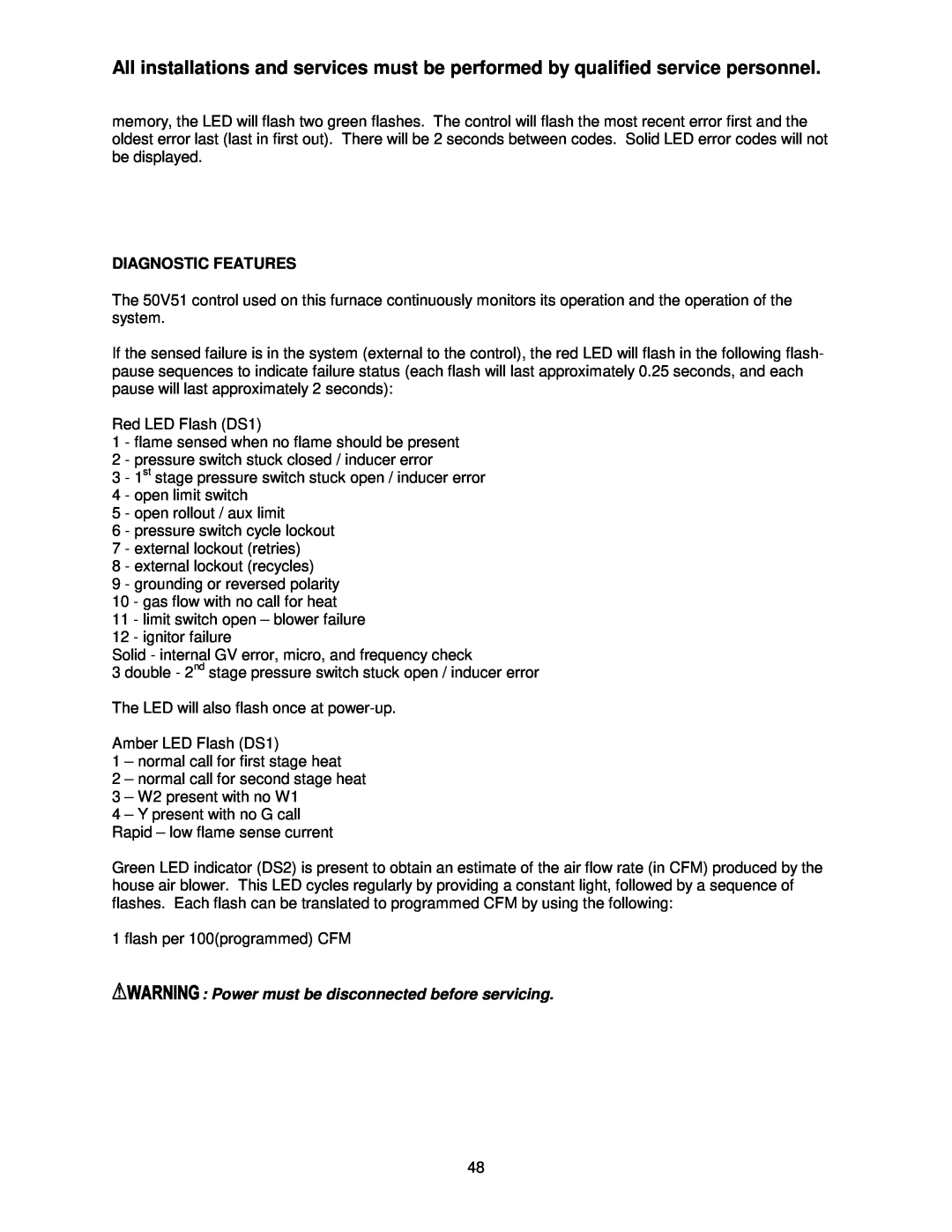

DIAGNOSTIC FEATURES

Power must be disconnected before servicing

TROUBLESHOOTING GUIDE

IS INDUCER RUNNING ON LOW SPEED? YES DOES THE HOT

DO BURNERS STAY LIT PAST PROOF OF FLAME CHECK?

REPLACE THE 50V51-843CONTROL

DOESBURNERSHUT OFF

Appendix -AReplacement Parts List

Page

Page

Page

Appendix - B Wiring Diagrams