All installations and services must be performed by qualified service personnel.

3.THERMOSTAT CONNECTIONS AND ANTICIPATOR SETTING NOTICE: For

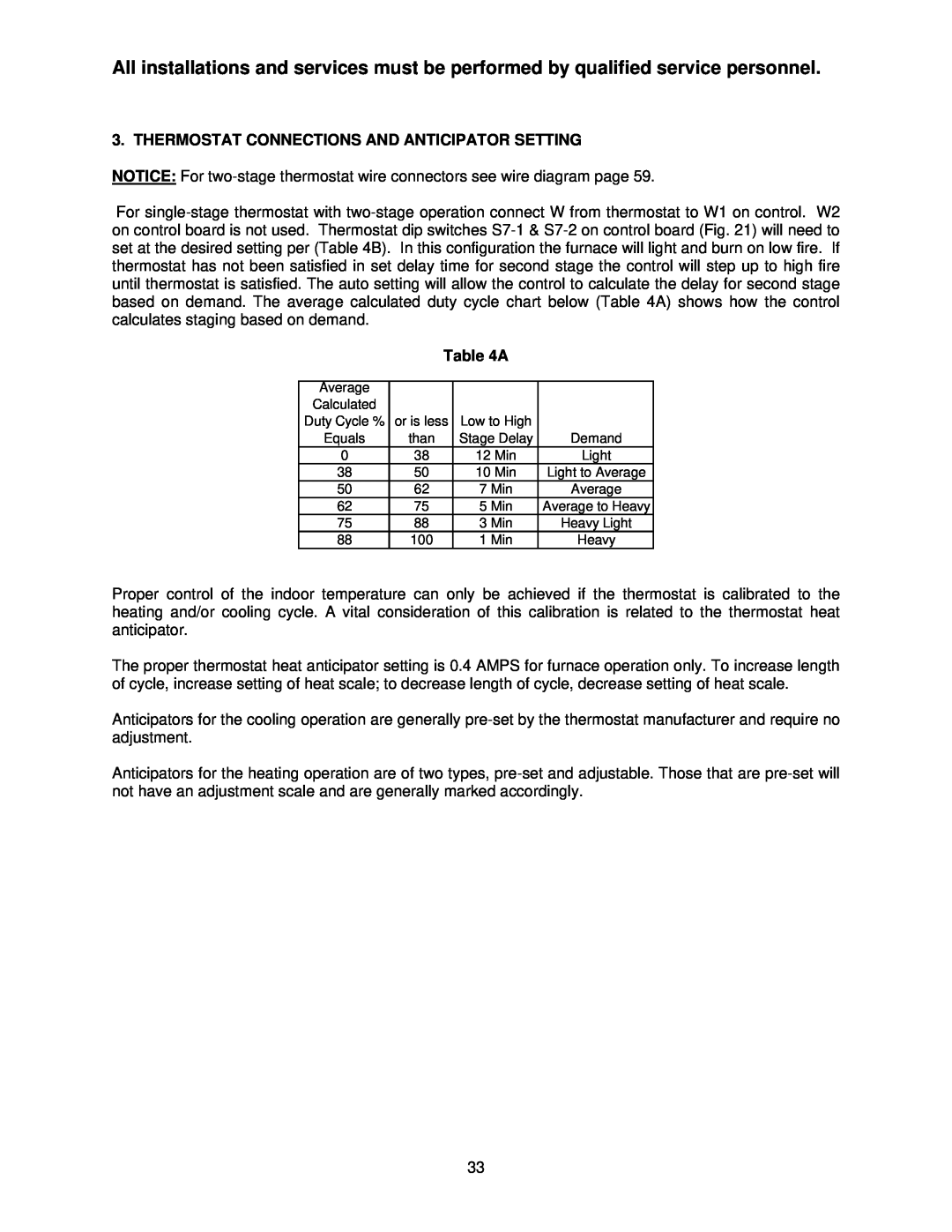

For

Table 4A

Average |

|

|

|

Calculated |

|

|

|

Duty Cycle % | or is less | Low to High |

|

Equals | than | Stage Delay | Demand |

0 | 38 | 12 Min | Light |

38 | 50 | 10 Min | Light to Average |

50 | 62 | 7 Min | Average |

62 | 75 | 5 Min | Average to Heavy |

75 | 88 | 3 Min | Heavy Light |

88 | 100 | 1 Min | Heavy |

Proper control of the indoor temperature can only be achieved if the thermostat is calibrated to the heating and/or cooling cycle. A vital consideration of this calibration is related to the thermostat heat anticipator.

The proper thermostat heat anticipator setting is 0.4 AMPS for furnace operation only. To increase length of cycle, increase setting of heat scale; to decrease length of cycle, decrease setting of heat scale.

Anticipators for the cooling operation are generally

Anticipators for the heating operation are of two types,

33