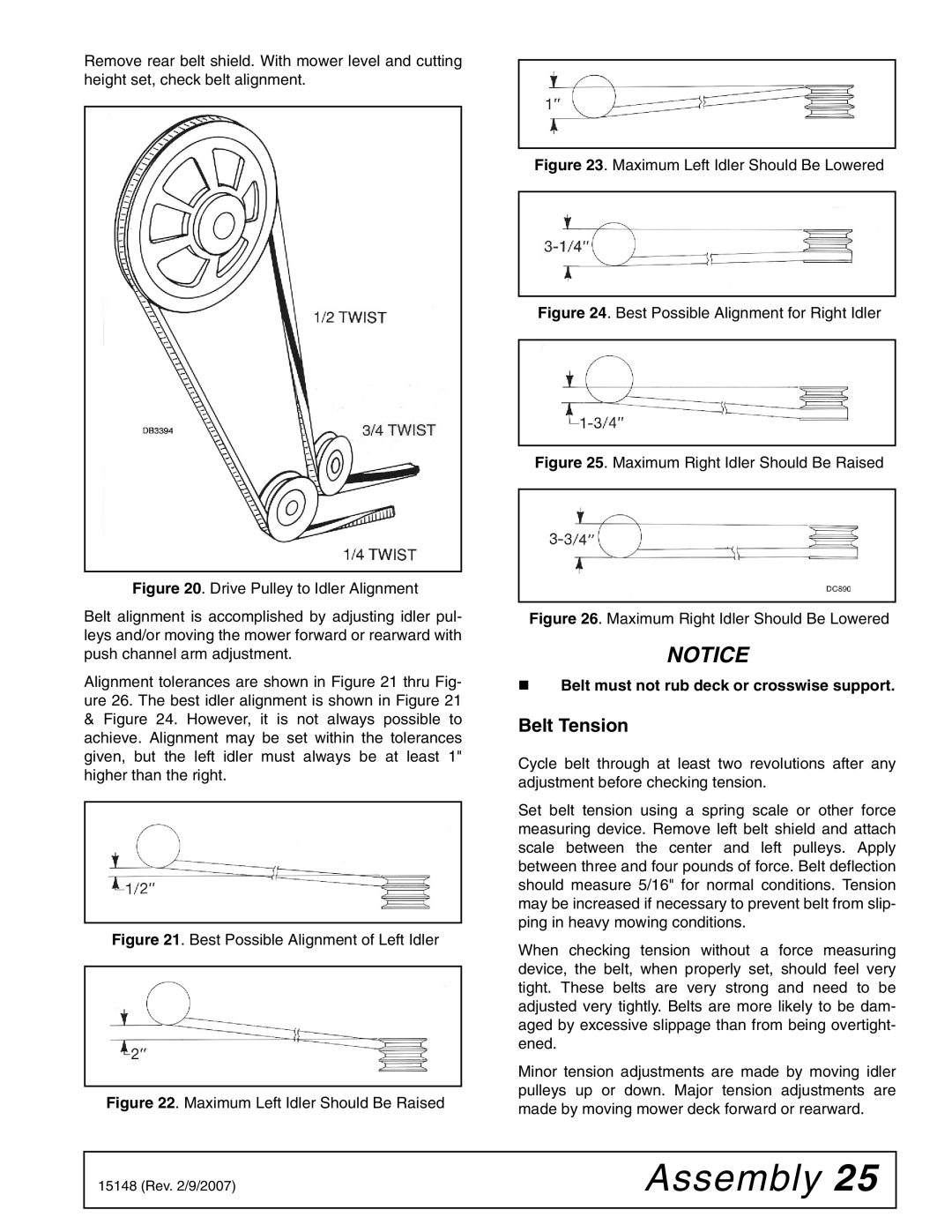

Remove rear belt shield. With mower level and cutting height set, check belt alignment.

Figure 20. Drive Pulley to Idler Alignment

Belt alignment is accomplished by adjusting idler pul- leys and/or moving the mower forward or rearward with push channel arm adjustment.

Alignment tolerances are shown in Figure 21 thru Fig- ure 26. The best idler alignment is shown in Figure 21

&Figure 24. However, it is not always possible to achieve. Alignment may be set within the tolerances given, but the left idler must always be at least 1" higher than the right.

Figure 21. Best Possible Alignment of Left Idler

Figure 22. Maximum Left Idler Should Be Raised

Figure 23. Maximum Left Idler Should Be Lowered

Figure 24. Best Possible Alignment for Right Idler

Figure 25. Maximum Right Idler Should Be Raised

Figure 26. Maximum Right Idler Should Be Lowered

NOTICE

Belt must not rub deck or crosswise support.

Belt Tension

Cycle belt through at least two revolutions after any adjustment before checking tension.

Set belt tension using a spring scale or other force measuring device. Remove left belt shield and attach scale between the center and left pulleys. Apply between three and four pounds of force. Belt deflection should measure 5/16" for normal conditions. Tension may be increased if necessary to prevent belt from slip- ping in heavy mowing conditions.

When checking tension without a force measuring device, the belt, when properly set, should feel very tight. These belts are very strong and need to be adjusted very tightly. Belts are more likely to be dam- aged by excessive slippage than from being overtight- ened.

Minor tension adjustments are made by moving idler pulleys up or down. Major tension adjustments are made by moving mower deck forward or rearward.

15148 (Rev. 2/9/2007) | Assembly 25 |

|

|