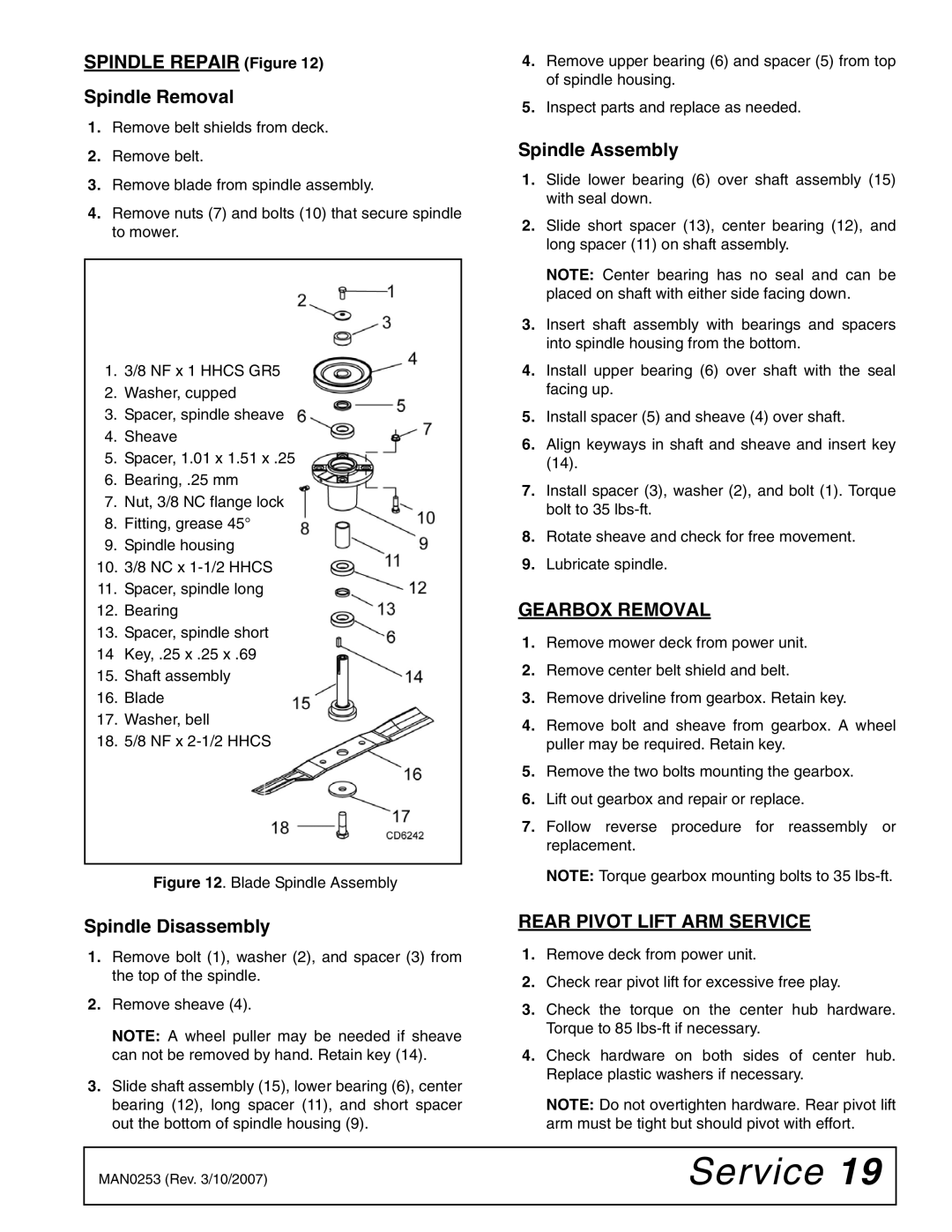

SPINDLE REPAIR (Figure 12)

Spindle Removal

1.Remove belt shields from deck.

2.Remove belt.

3.Remove blade from spindle assembly.

4.Remove nuts (7) and bolts (10) that secure spindle to mower.

1.3/8 NF x 1 HHCS GR5

2.Washer, cupped

3.Spacer, spindle sheave

4.Sheave

5.Spacer, 1.01 x 1.51 x .25

6.Bearing, .25 mm

7.Nut, 3/8 NC flange lock

8.Fitting, grease 45°

9.Spindle housing

10.3/8 NC x

11.Spacer, spindle long

12.Bearing

13.Spacer, spindle short

14Key, .25 x .25 x .69

15.Shaft assembly

16.Blade

17.Washer, bell

18.5/8 NF x

Figure 12. Blade Spindle Assembly

Spindle Disassembly

1.Remove bolt (1), washer (2), and spacer (3) from the top of the spindle.

2.Remove sheave (4).

NOTE: A wheel puller may be needed if sheave can not be removed by hand. Retain key (14).

3.Slide shaft assembly (15), lower bearing (6), center bearing (12), long spacer (11), and short spacer out the bottom of spindle housing (9).

4.Remove upper bearing (6) and spacer (5) from top of spindle housing.

5.Inspect parts and replace as needed.

Spindle Assembly

1.Slide lower bearing (6) over shaft assembly (15) with seal down.

2.Slide short spacer (13), center bearing (12), and long spacer (11) on shaft assembly.

NOTE: Center bearing has no seal and can be placed on shaft with either side facing down.

3.Insert shaft assembly with bearings and spacers into spindle housing from the bottom.

4.Install upper bearing (6) over shaft with the seal facing up.

5.Install spacer (5) and sheave (4) over shaft.

6.Align keyways in shaft and sheave and insert key (14).

7.Install spacer (3), washer (2), and bolt (1). Torque bolt to 35

8.Rotate sheave and check for free movement.

9.Lubricate spindle.

GEARBOX REMOVAL

1.Remove mower deck from power unit.

2.Remove center belt shield and belt.

3.Remove driveline from gearbox. Retain key.

4.Remove bolt and sheave from gearbox. A wheel puller may be required. Retain key.

5.Remove the two bolts mounting the gearbox.

6.Lift out gearbox and repair or replace.

7.Follow reverse procedure for reassembly or replacement.

NOTE: Torque gearbox mounting bolts to 35

REAR PIVOT LIFT ARM SERVICE

1.Remove deck from power unit.

2.Check rear pivot lift for excessive free play.

3.Check the torque on the center hub hardware. Torque to 85

4.Check hardware on both sides of center hub. Replace plastic washers if necessary.

NOTE: Do not overtighten hardware. Rear pivot lift arm must be tight but should pivot with effort.

MAN0253 (Rev. 3/10/2007) | Service 19 |

|

|