BLADE SERVICING

NOTICE

■Do not handle blades with bare hands. Care- less or improper handling may result in serious injury.

Raise wings and lock in up position. Inspect blades before each use to determine that they are properly installed and in good condition. Check to be sure blades are snug but still swivel on blade pin (see Blade Installation). Replace any blade that is bent, exces- sively nicked, worn or has any other damage. Small nicks can be ground out when sharpening.

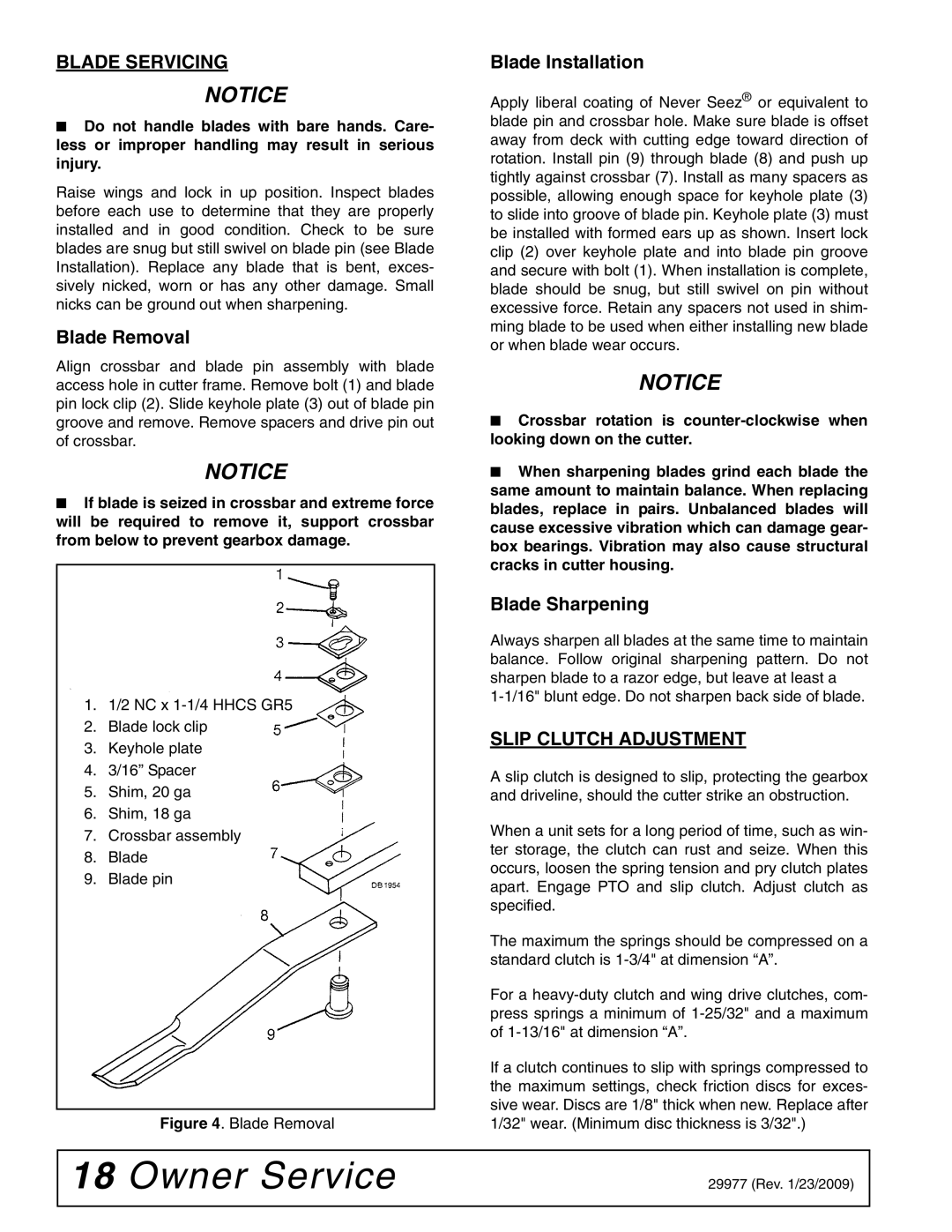

Blade Removal

Align crossbar and blade pin assembly with blade access hole in cutter frame. Remove bolt (1) and blade pin lock clip (2). Slide keyhole plate (3) out of blade pin groove and remove. Remove spacers and drive pin out of crossbar.

NOTICE

■If blade is seized in crossbar and extreme force will be required to remove it, support crossbar from below to prevent gearbox damage.

1.1/2 NC x

2.Blade lock clip

3.Keyhole plate

4.3/16” Spacer

5.Shim, 20 ga

6.Shim, 18 ga

7.Crossbar assembly

8.Blade

9.Blade pin

Figure 4. Blade Removal

Blade Installation

Apply liberal coating of Never Seez® or equivalent to blade pin and crossbar hole. Make sure blade is offset away from deck with cutting edge toward direction of rotation. Install pin (9) through blade (8) and push up tightly against crossbar (7). Install as many spacers as possible, allowing enough space for keyhole plate (3) to slide into groove of blade pin. Keyhole plate (3) must be installed with formed ears up as shown. Insert lock clip (2) over keyhole plate and into blade pin groove and secure with bolt (1). When installation is complete, blade should be snug, but still swivel on pin without excessive force. Retain any spacers not used in shim- ming blade to be used when either installing new blade or when blade wear occurs.

NOTICE

■Crossbar rotation is

■When sharpening blades grind each blade the same amount to maintain balance. When replacing blades, replace in pairs. Unbalanced blades will cause excessive vibration which can damage gear- box bearings. Vibration may also cause structural cracks in cutter housing.

Blade Sharpening

Always sharpen all blades at the same time to maintain balance. Follow original sharpening pattern. Do not sharpen blade to a razor edge, but leave at least a

SLIP CLUTCH ADJUSTMENT

A slip clutch is designed to slip, protecting the gearbox and driveline, should the cutter strike an obstruction.

When a unit sets for a long period of time, such as win- ter storage, the clutch can rust and seize. When this occurs, loosen the spring tension and pry clutch plates apart. Engage PTO and slip clutch. Adjust clutch as specified.

The maximum the springs should be compressed on a standard clutch is

For a

If a clutch continues to slip with springs compressed to the maximum settings, check friction discs for exces- sive wear. Discs are 1/8" thick when new. Replace after 1/32" wear. (Minimum disc thickness is 3/32".)

18 Owner Service | 29977 (Rev. 1/23/2009) |

|

|