Liebert XDH Component Locations and Model Number Nomenclature

1.0LIEBERT XDH COMPONENT LOCATIONS AND MODEL NUMBER NOMENCLATURE

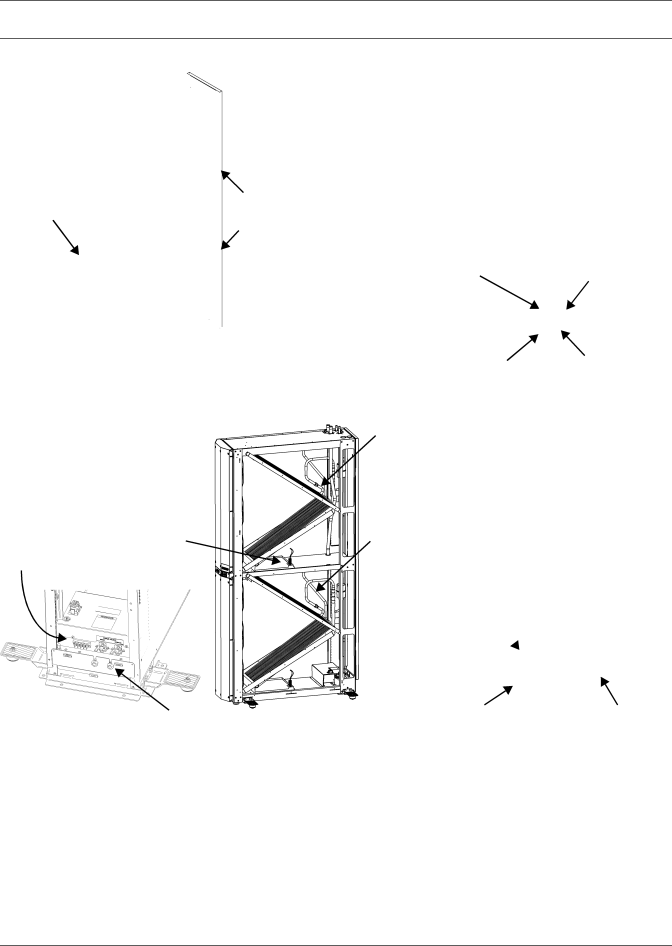

Figure 1 Liebert XDH component locations

Controls

Cooling

Air Supply

Vents

FRONT |

| |

| FRONT | |

Condensate | Condensate Pan | |

and Detection | ||

Detection | ||

Option (also in | ||

Connections | ||

bottom circuit) | ||

|

REAR

Electrical

Connections

FRONT

(Top View)

Air

Return

Vents

Return Piping | Return Piping | |

Connection - | ||

Connection - | ||

Bottom Circuit | ||

Top Circuit | ||

|

| Supply Piping | Supply Piping |

| Connection - | Connection - |

REAR | Bottom Circuit | Bottom Circuit |

|

| |

| Upper | FRONT |

| Refrigeration | |

| (Bottom View) | |

| Circuit | |

|

|

Lower

Refrigeration

Circuit

Casters (one at each corner) ![]()

Adjustable Foot | Stabilizers (one |

(one at each corner) | at each corner) |

Figure 2 Liebert XDH model number nomenclature

|

|

|

|

|

| Example: XDH32BK— |

|

|

|

|

|

| ||||

XD | H | 32 | B | K | — | — | 0 | |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

Liebert |

|

|

| 20 = Model size |

| K = |

|

| — = Domestic packaging |

| ||||||

|

|

| 32 = Model size |

| S = |

|

| E = Export packaging |

| |||||||

density system |

|

|

|

|

|

|

|

|

|

|

|

| ||||

| Horizontal |

| row cooler |

|

|

|

|

|

|

|

| Revision level | ||||

| B = Base unit |

|

| — = Hard piped | ||||||||||||

|

|

|

|

|

| D = Condensate detection |

| P = | ||||||||

|

|

|

|

|

|

|

|

|

| R = Removable Coupling |

|

| ||||

1