bühler

Allied

OPERATION

General Operating Notes: The following section provides general information that can be applied towards your specific application. Ensure that you’ve read and understood this manual and your Tractor Manual. Observe all safety precautions and follow local laws pertaining to the use of your loader and tractor.

Hydraulics: Under normal conditions, operate the tractor’s engine at ½ throttle.

Note: In cold weather, tractors with load sense hydraulic systems require longer

In cold weather, operate the tractor’s engine at idle speed until the hydraulic fluid is warmed up. Slowly cycle the loader and attachment several times to further warm the hydraulic fluid. High engine speed when the hydraulic fluid is cold will cause the pump to wear prematurely and may cause the loader to operate erratically.

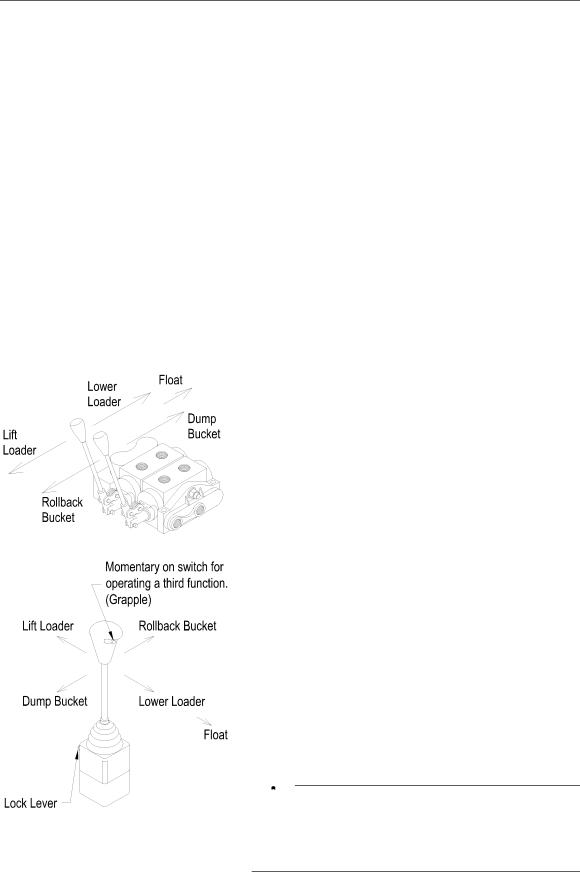

The hydraulic hoses should be connected to the loader valve such that pushing forward on handles lowers the loader or dumps the attachment. When using the Allied Remote Hydraulic Control pushing forward should lower the loader while pushing directly right should dump the attachment.

The Allied Remote Hydraulic Control is equipped with a momentary push button switch and a lock. The push button is for operating a third function when an electric diverter is installed. The third function is normally for operating a grapple. When the button is depressed the valve ports are open to the grapple cylinders. Shifting the joystick to the left while button is depressed will close the grapple and shifting to the right will open.

IMPORTANT: Always feather the grapple when closing or opening to avoid unnecessary shock loads on grapple components.

![]()

![]() WARNING

WARNING

Keep grapple closed at all times when bucket is empty and carry bucket low to the ground. Avoid operating near power wires.

- 11 - | P4493 |