INSTALLING CONTROL CUT DEVICE

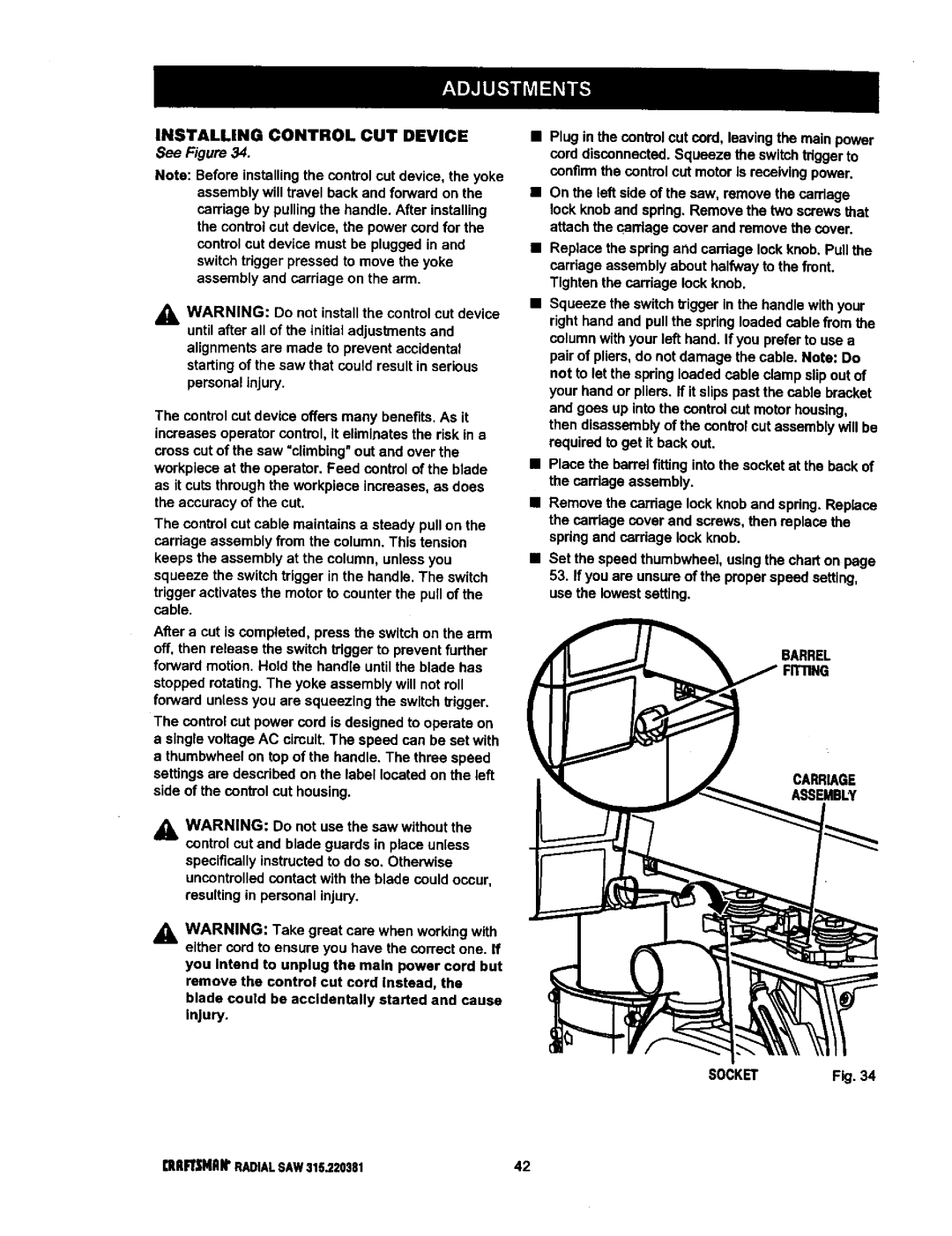

See Figure 34.

Note: Before installing the controlcut device, the yoke assembly will travel back and forward on the carriage by pullingthe handle. After installing the controlcut device, the power cordfor the controlcut device must be plugged in and

switch triggerpressed to move the yoke assembly and carriage on the arm.

WARNING: Do not install the control cut device until after all of the initial adjustments and alignments are made to prevent accidental starting of the saw that could result in serious personal injury.

The control cut device offers many benefits.As it Increases operator control,It eliminatesthe risk in a cross cut of the saw "climbing"out and over the

workplace at the operator. Feed control of the blade as it cuts throughthe workpiece increases,as does the accuracy of the cut.

The control cutcable maintainsa steady pullon the carriage assemblyfrom the column.This tension keeps the assembly at the column,unlessyou

squeeze the switchtrigger in the hendte.The switch triggeractivatesthe motor to counter the pullof the cable.

After a cut is completed, press the switchon the arm off, then release the switch triggerto preventfurther forward motion.Hold the handle until the blade has stopped rotating.The yoke assembly will not roll forward unlessyou are squeezing the switch trigger.

The control cut power cord is designedto operate on

asingle voltageAC circuit.The speed can be set with a thumbwheelon top of the handle. The three speed settingsare describedon the label locatedon the left side of the control cut housing.

_k WARNING: Do not use the saw withoutthe controlcut and blade guards in place unless

specifically Instructed to do so. Otherwise uncontrolled contact with the blade could occur, resulting in personal injury.

_1= WARNING: Take great care when working with either cord to ensure you have the correct one. If

you Intend to unplug the main power cord but remove the control cut cord Instead, the blade could be accidentally started and cause

Injury.

•Plug in the controlcut cord, leavingthe main power cord disconnected.Squeeze the switchtriggerto confirm the control cut motoris receivingpower.

•On the left side of the saw, remove the carriage lock knob and spdng. Remove the two screws that attach the carriage cover and remove the cover.

•Replace the spring and cardage lock knob. Pull the carriage assembly about halfway to the front. Tighten the carriage lock knob.

•Squeeze the switch trigger in the handle with your right hand and pull the spring loaded cable from the column with your left hand. If you prefer to use a pair of pliers, do not damage the cable. Note: Do not to let the spring loaded cable clamp slip out of your hand or pliers. If it slips past the cable bracket and goes up Into the control cut motor housthg, then disassembly of the control cut assembly will be required to get it back out.

•Place the barrel fitting into the socket at the back of the carriage assembly.

•Remove the carriage lock knob and spring. Replace the carriage cover and screws, then replace the spring and carriage lock knob.

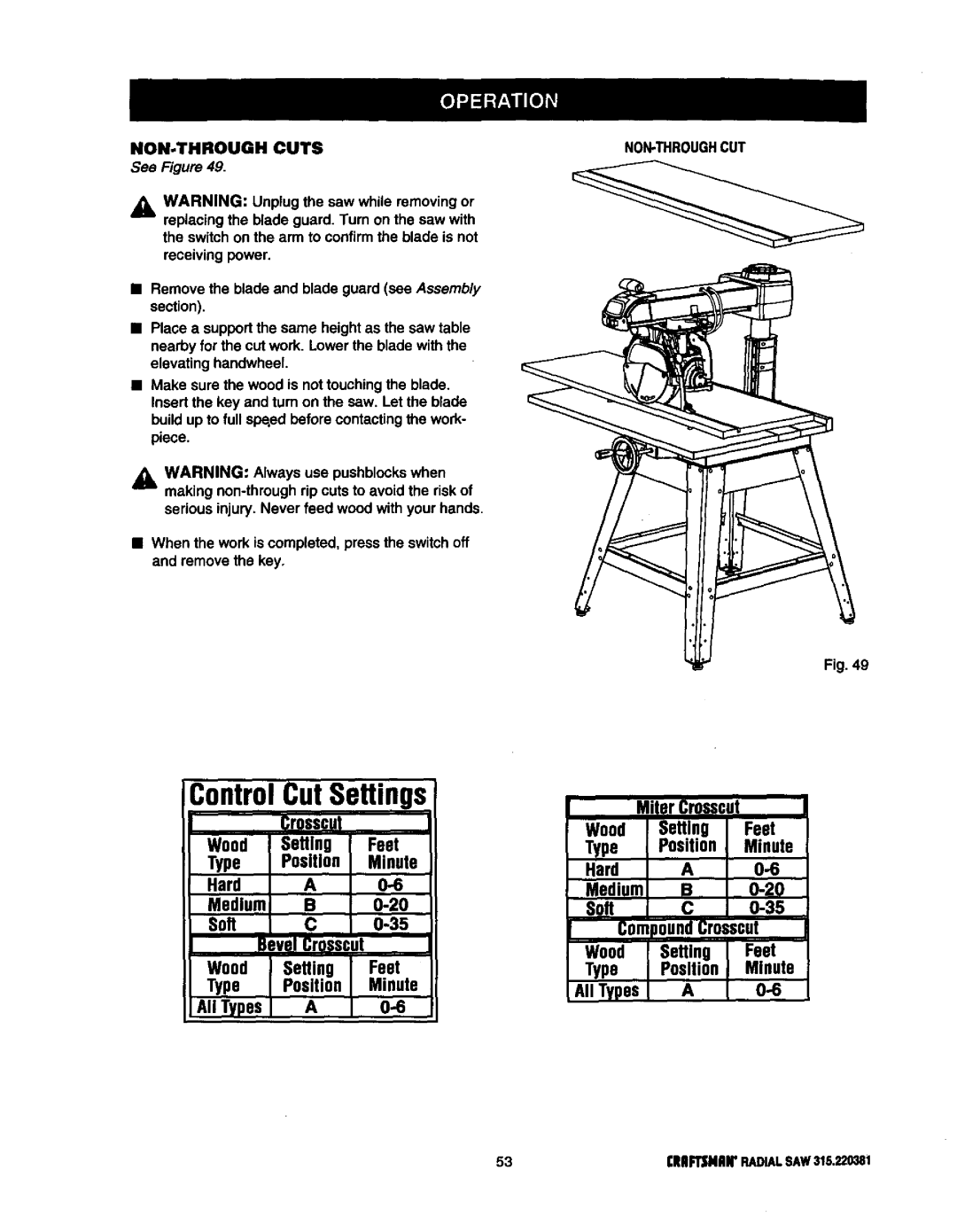

•Set the speed thumbwhee], using the chart on page

53.If you are unsure of the proper speed setting, use the lowest setting.

BARREL

CARRIAGE

ASSEMBLY

SOCKETF_.34

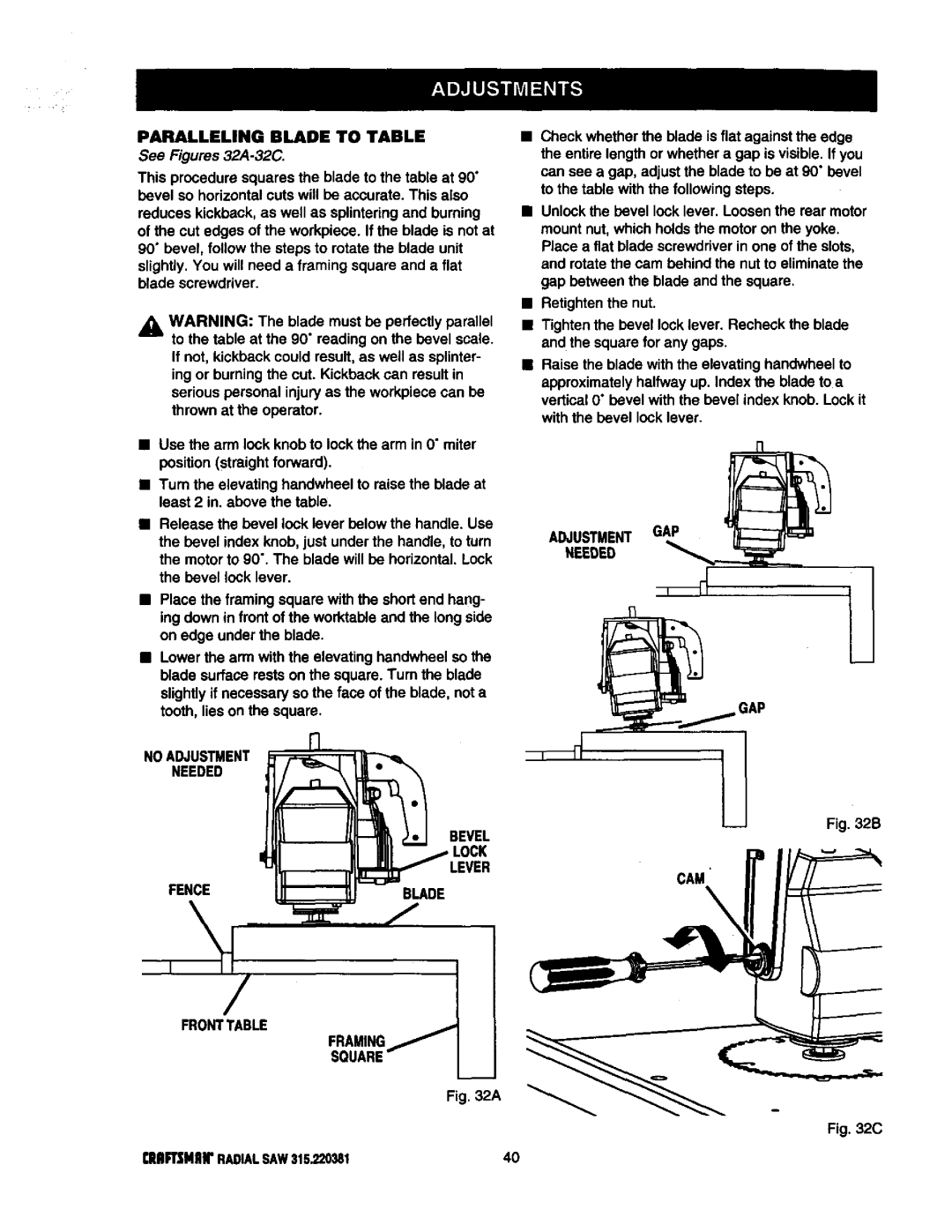

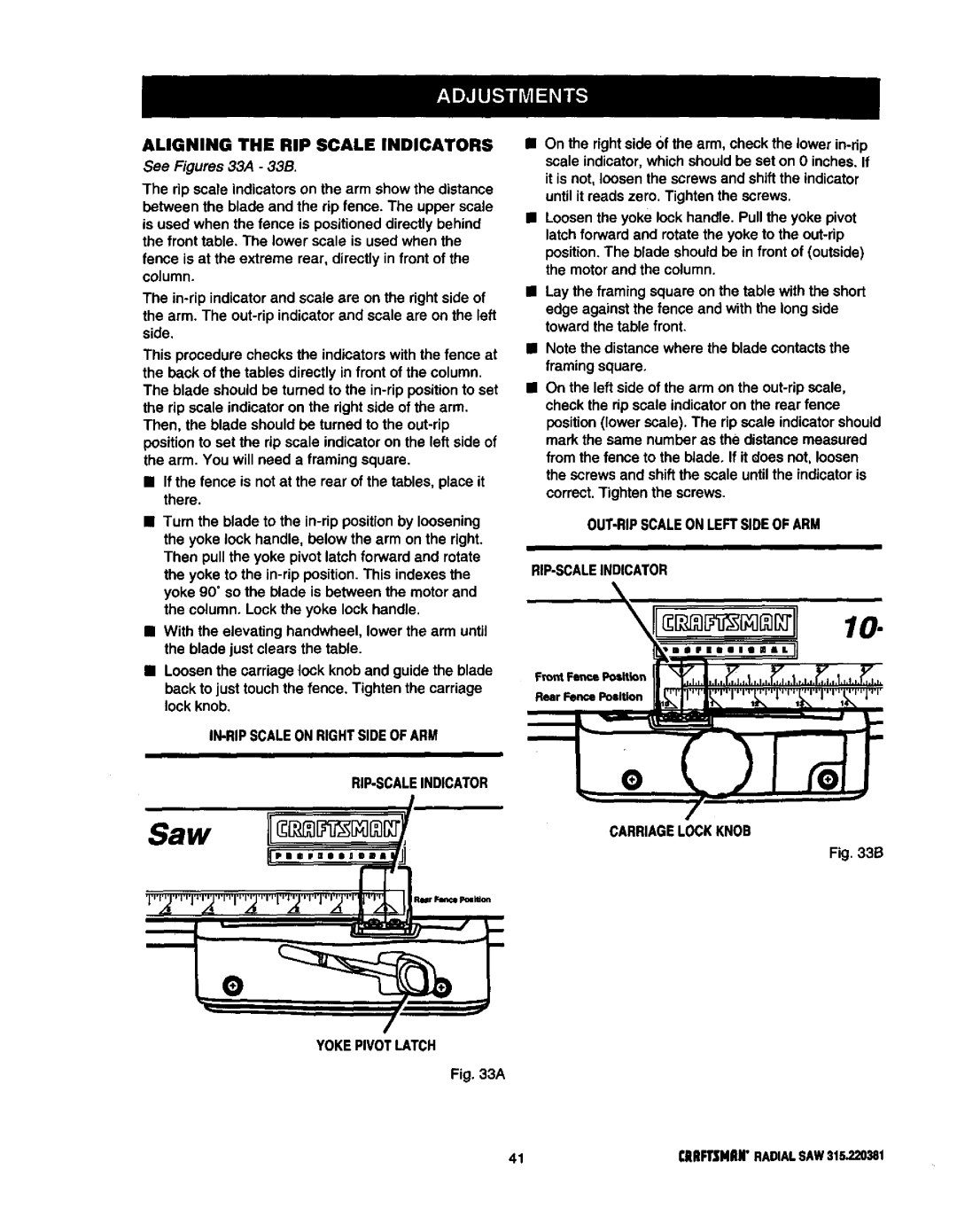

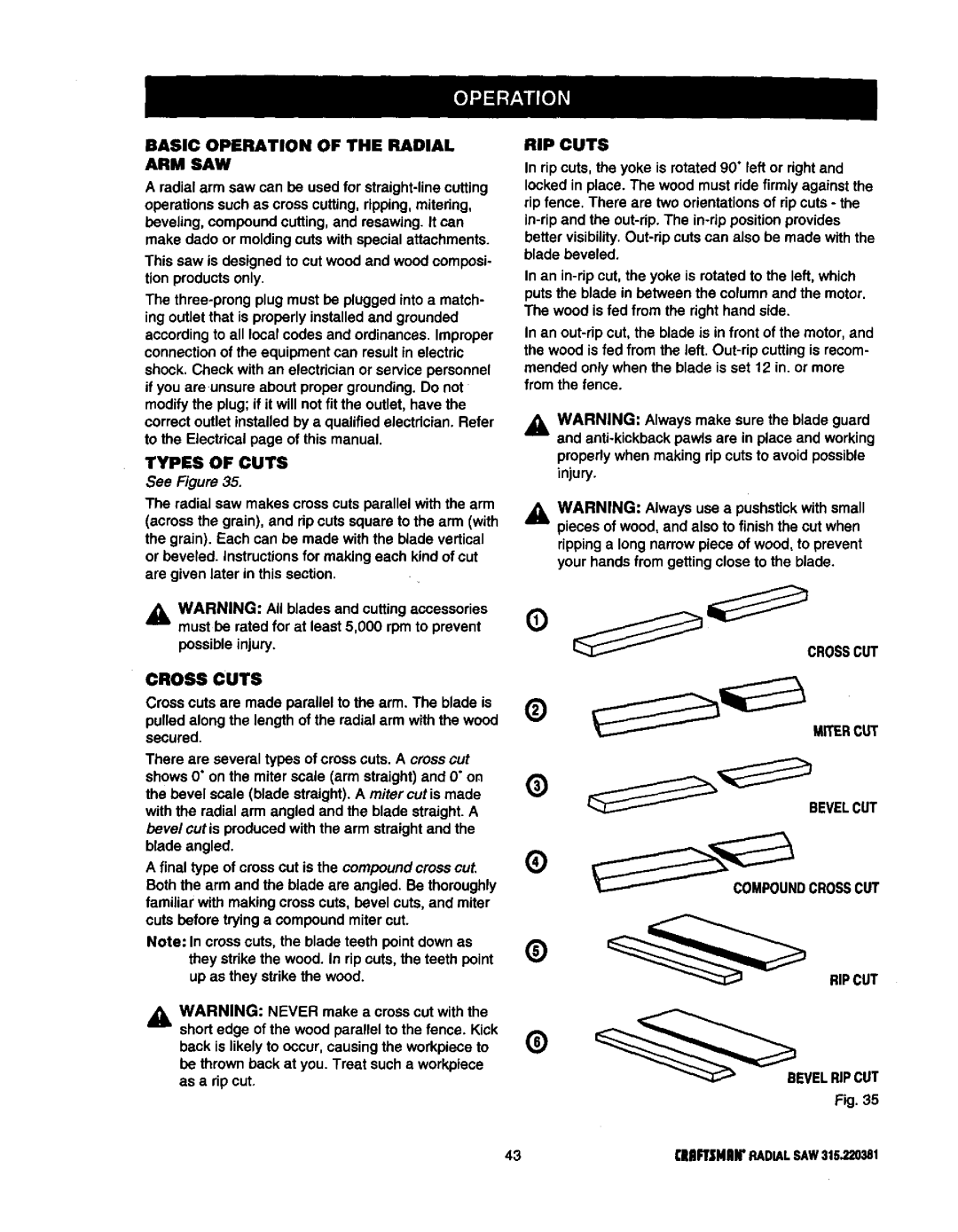

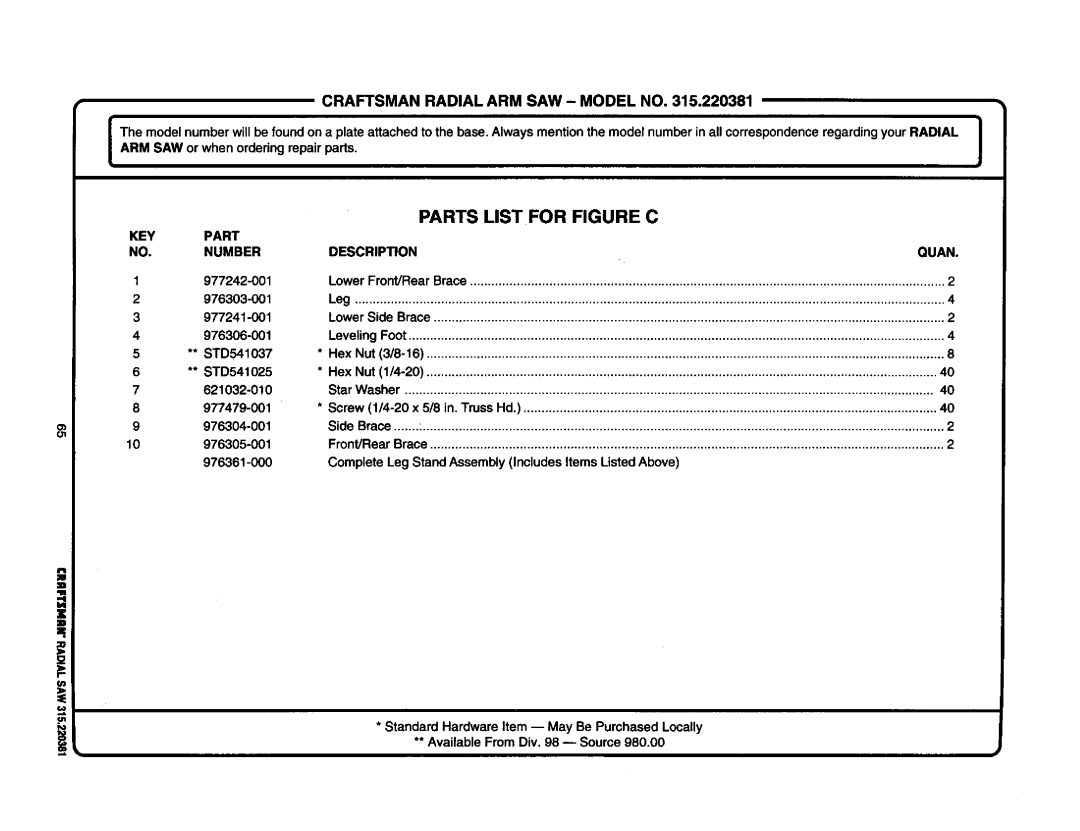

[ItlIFTSNAItRADIAL SAW 315.?.20381 | 42 |