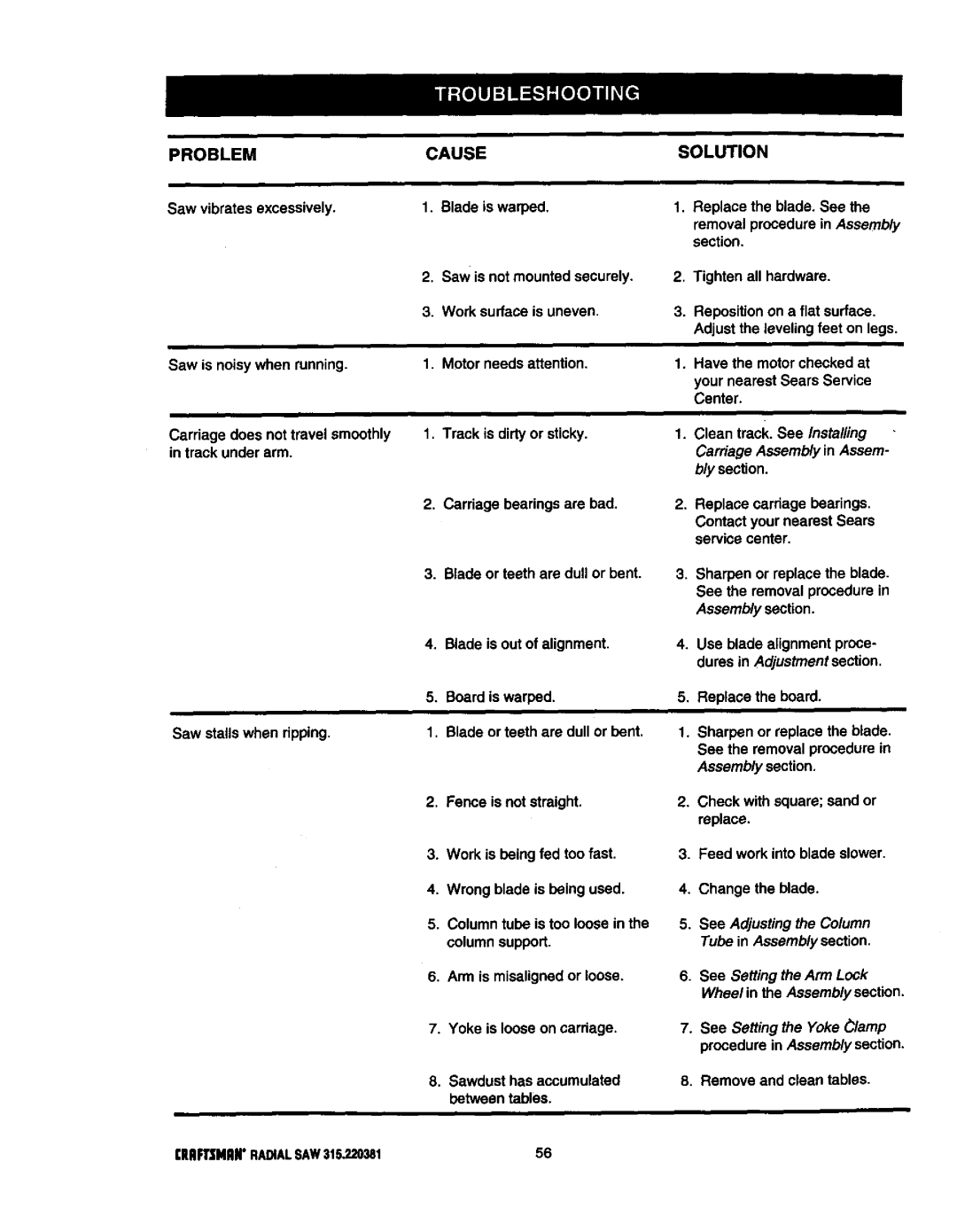

PROBLEM

Miter or cross cuts are not true.

Wood edges away from fence when ripping.

CAUSE

1.Scale pointer is not correct.

2.Column is out of alignment.

3.Carriage is misaligned.

4.Yoke is loose on carriage.

5.Arm is out of alignment.

6.Sawdust has collected between tables.

7.Table top is not parallel to the arm.

8.Fence/tables are not straight.

t. Blade is not parallel with fence.

SOLUTION

1.Reset the pointer at the top rear of arm.

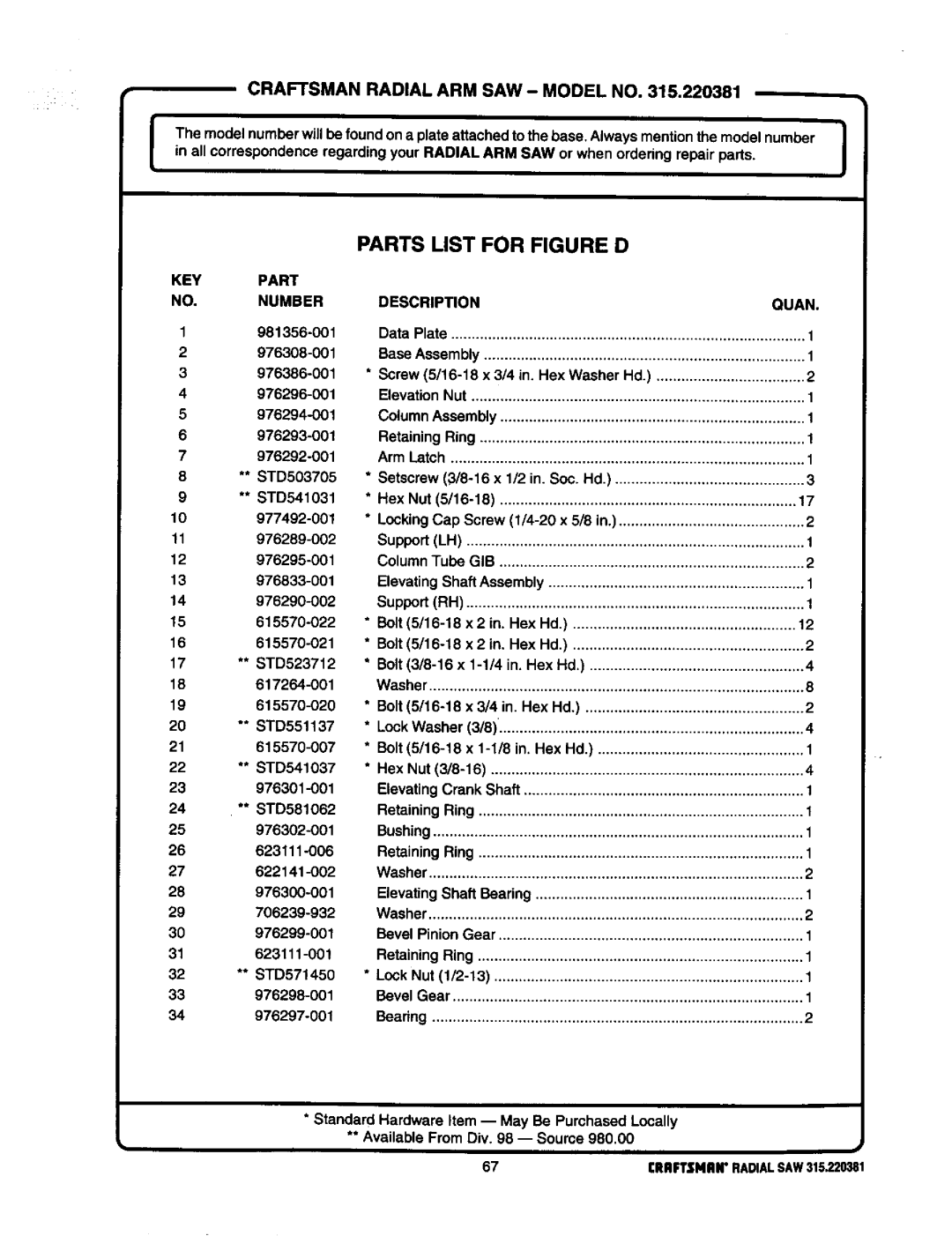

2.See Adjusting the Column Tube in Assembly section.

3.See Setting the Arm Lock

Wheel in the Assembly section.

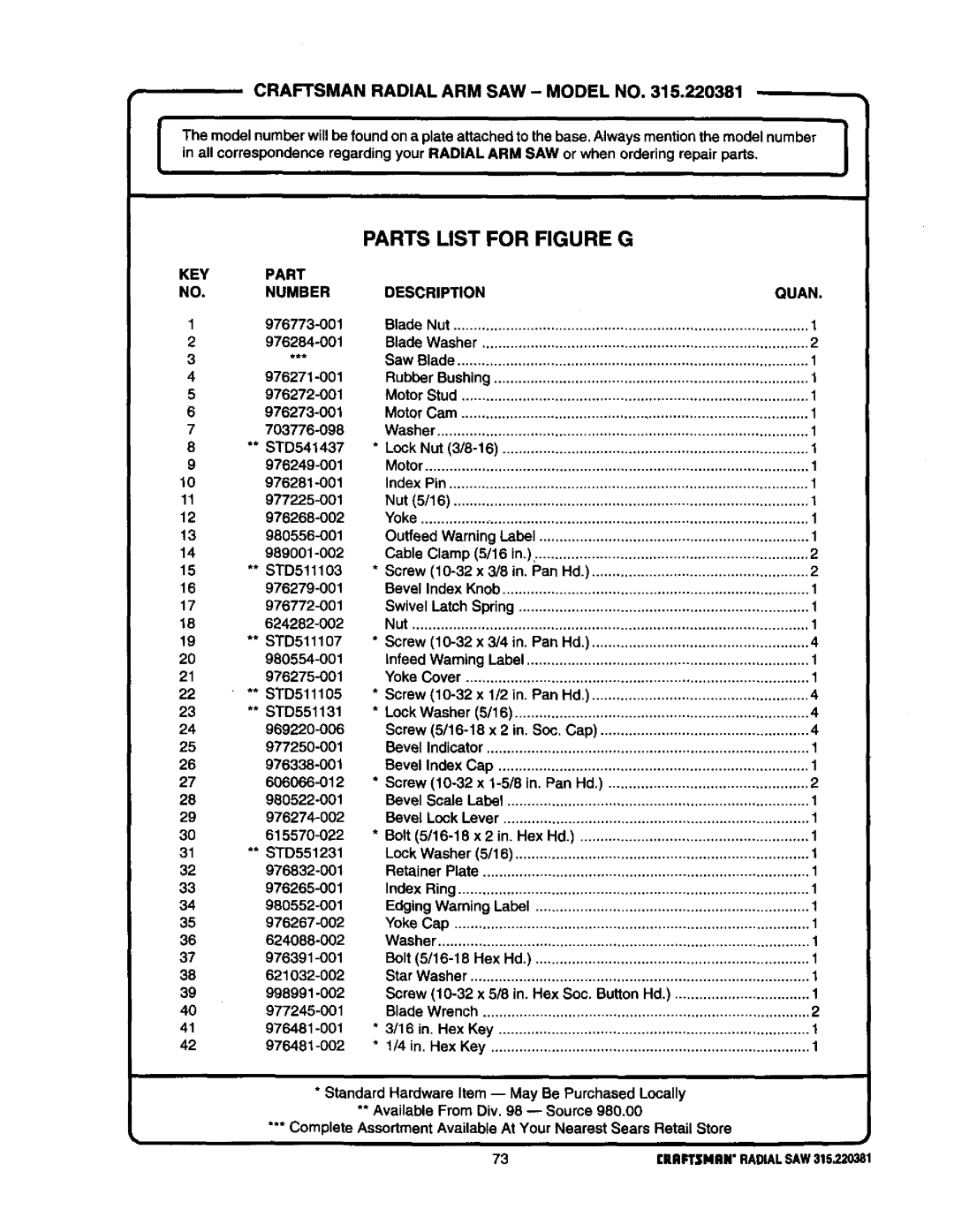

4.See Setting the Yoke Clamp procedure in Assembly section.

5.See Aligning Arm for Cross Cuts in Adjustmentssection.

6.Remove and clean tables.

7.See Leveling Table Supports and Leveling the Front Table in the Assembly section,

8.Check with square; sand or replace.

1.See Squaring the Blade to the

Fence procedure in the Adjust- ments section.

2.Arm is not perpendicular to fence.

3.Riving knife needs adjustment.

2.See Aligning the Arm for Cross Cuts procedure in the Adjust- ments section.

3.See Aligning the RivingKnife to the Blade procedure in the Adjustments section.

Depth of cut varies from one end of wood to the other.

Riving knife strikes wood during a cut.

1. | Table is not parallel to arm, | 1= See Leveling Table Supports | |

|

|

| and Leveling the Front Table in |

|

|

| the Assembly section. |

2. | Column tube is loose in column | 2. | See Adjusting the Column |

| support. |

| Tube in Assembly section, |

3. | Arm is loose or misaligned. | 3. | See Setting the Arm Lock |

|

|

| Wheel in the Assembly section, |

1. | Riving knife not aligned with. | 1. See Aligning the Riving Knife to | |

| blade, |

| the Blade procedure in the |

|

|

| Adjustmentssection. |

CUKsNArRADIALSAW315.22038158