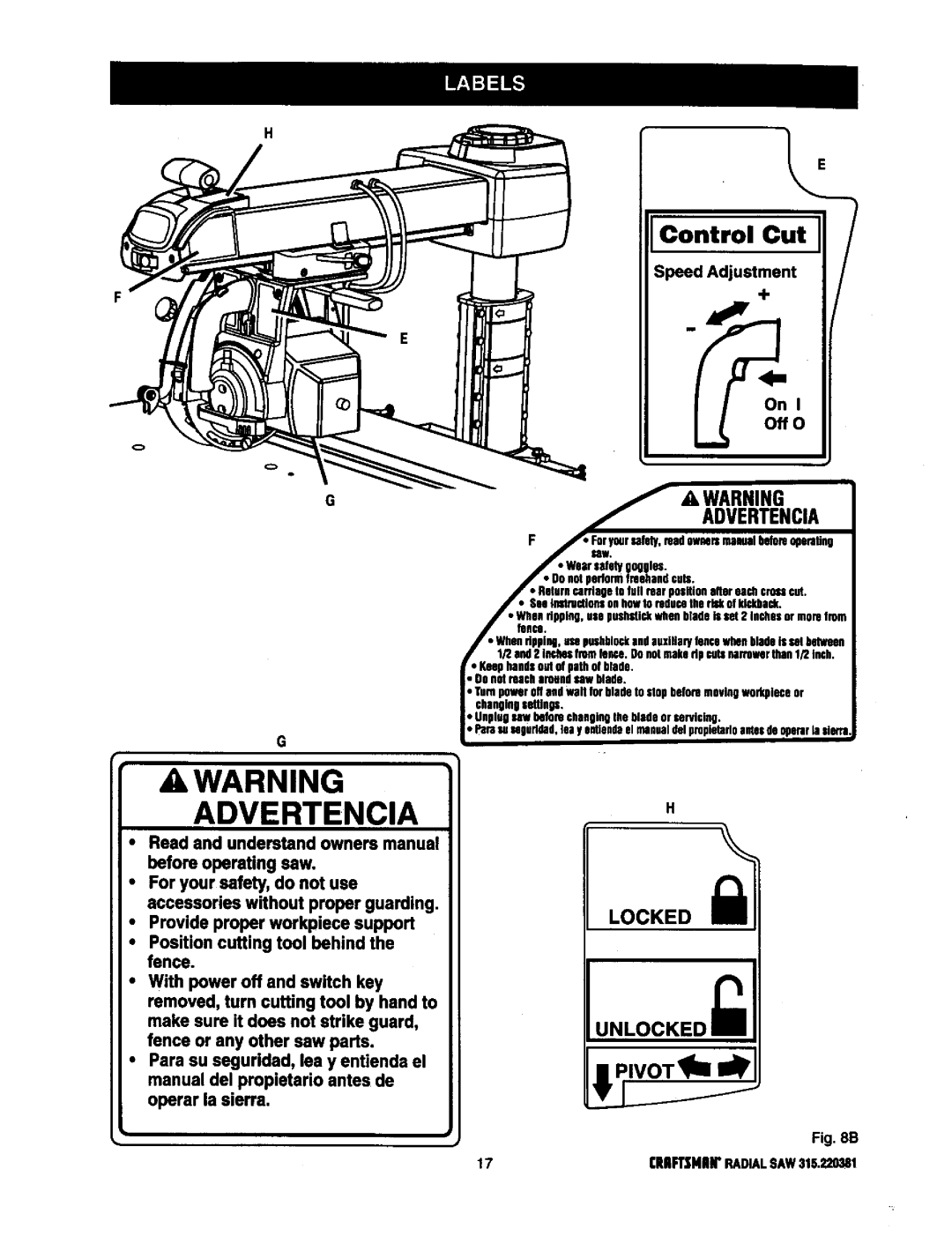

•GUARD AGAINST KICKBACK. Kickbackcan occur when the blade stalls, driving the work piece back toward the operator. It can cause your hand to contact the blade, resulting in serious personal

injury. Stay out of the blade path and turn switch off immediately if blade binds or stalls.

•DO NOT USE A PERSON AS A SUBSTITUTE

FOR A TABLE if additional support is needed. Use a support the same height as the table.

•USE A SUPPORT FOR THE SIDES AND BACK OF THE SAW TABLE when sawing wide or long workpieces to minimize the risk of blade pinching and kickback. Use a sturdy "outrigger"support to prevent tipping if a table extension more than 24 inches long is attached to the saw.

•CUT ONLY WOOD, PLASTIC OR

•BEFORE MAKING A CUT, be sure all adjustments are secure.

•NEVER cut more than one piece at a time. DO

NOT STACK more than one workpiece on the saw table at a time.

•DO NOT REMOVE THE SAW'S BLADE GUARD. Never operate the saw with the blade guard removed. Make sure all guards are operating properly before each use.

•NEVER PERFORM ANY OPERATION FREE- HAND. Always place the workpiece to be cut on the saw table and position it firmly against the fence as a backstop.

•USE THE RIP FENCE. Always use a fence or straight edge guide when ripping.

•BE SURE THE BLADE PATH IS FREE OF NAILS. Inspect for and remove all nails from lumber before cutting.

•BE SURE THE BLADE CLEARS THE WORK-

PIECE. Never start the saw with the blade touching the stock.

•KEEP HANDS AWAY FROM CUTTING AREA. Do not reach underneath work or in blade cutting path with your hands and fingers for any reason.

Always turn the power off when cut is complete.

•USE A PUSHBLOCK OR PUSHSTICK in rip mode for workpieces so small that your fingers go under the blade guard. NEVER TOUCH BLADE or other moving parts during use, for any reason.

•ALLOW THE MOTOR TO COME UP TO FULL SPEED before starting a cut to avoid blade binding or stalling.

ALWAYS PUSH THE WORKPIECE when ripping; never pull it toward the saw.

DO NOT FEED THE MATERIAL TOO QUICKLY. Do not force the workpiece against the blade.

•ALWAYS TURN OFF SAW before disconnecting it, to avoid accidental startingwhen reconnecting to the power supply. NEVER leave the saw unattended while connected to a power source.

•BEFORE CHANGING THE SETUP, REMOVING COVERS, GUARDS, OR BLADE; unplugthe saw and remove the switch key.

•KEEP TOOL DRY, CLEAN, AND FREE FROM OIL AND GREASE. Always use a clean cloth when cleaning. Never use brake fluids, gasoline,

KEEP BLADES CLEAN, SHARP AND WITH SUFFICIENT SET. Sharp blades minimize stalling and kickback. Keep blades free of rust, grease, and pitch.

being turned off.

_k WARNING: Blade coasts after " =

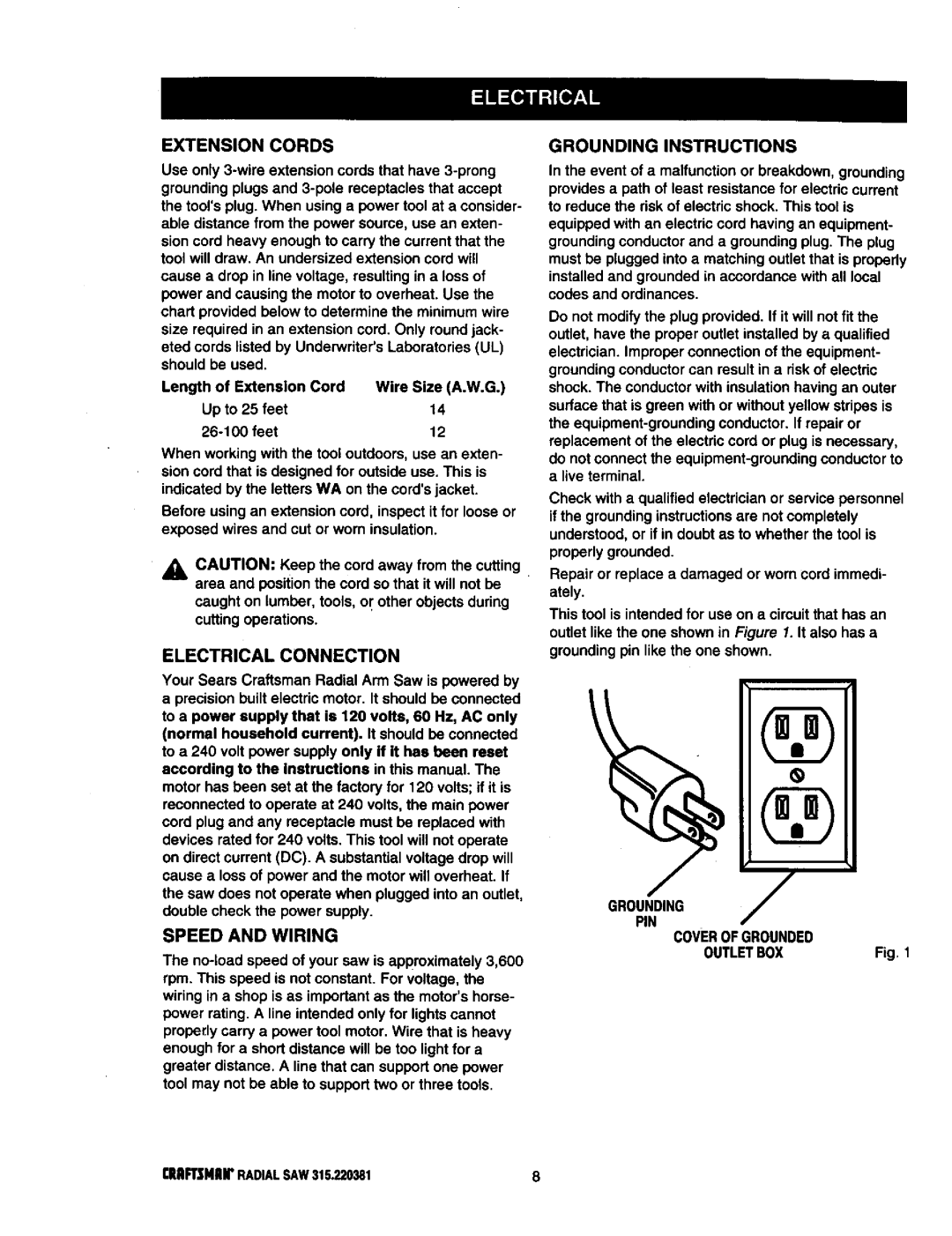

•USE ONLY OUTDOOR EXTENSION CORDS. Use only extension cords with the marking =Ac- ceptable for use with outdoor appliances;store indoorswhile not in use." Use extension cordswith an electrical rating not less than the saw'srating. Always disconnectthe extension cord from the outlet before disconnectingthe productfrom the extension cord.

INSPECT TOOL CORDS AND EXTENSION CORDS PERIODICALLY and, if damaged, have repaired by a qualified service technician at a Sears repair center. Stay constantlyaware of cord

locationand keep it well away from the moving blade.

•DO NOT ABUSE CORD. Never yank the cord to disconnectit from receptacle. Keep the cord from heat, oil, and sharp edges.

•SAVE THESE INSTRUCTIONS. Refer to them

frequently and use to instructother users. If you loan someone this tool, loan them these instruc- tions also.

SAVE THESE INSTRUCTIONS

Clltl_HIIIr RADIALSAW315.220381 | 6 |