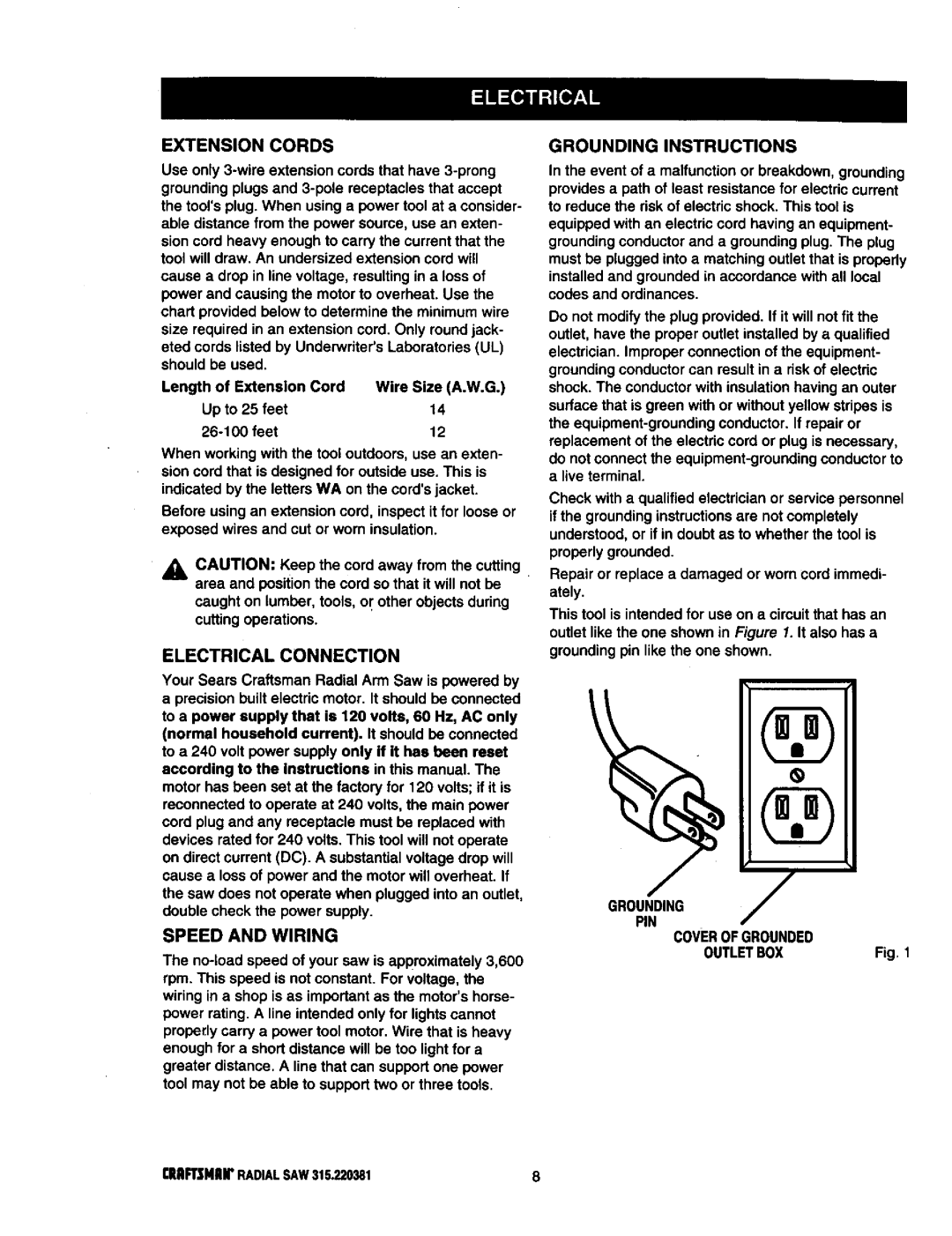

•USE THE PROPER EXTENSION CORD. Make

sure your extension cord is in good condition, Use only a cord heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. A wire gage size (A.W.G.) of at least 14 is recommended for an extension cord 25 feet

or less in length. If in doubt, use the next heavier

gage. The smaller the gage number, the heavier the cord,

•AVOID ACCIDENTAL STARTING. Be sure switch is off when plugging in the tool.

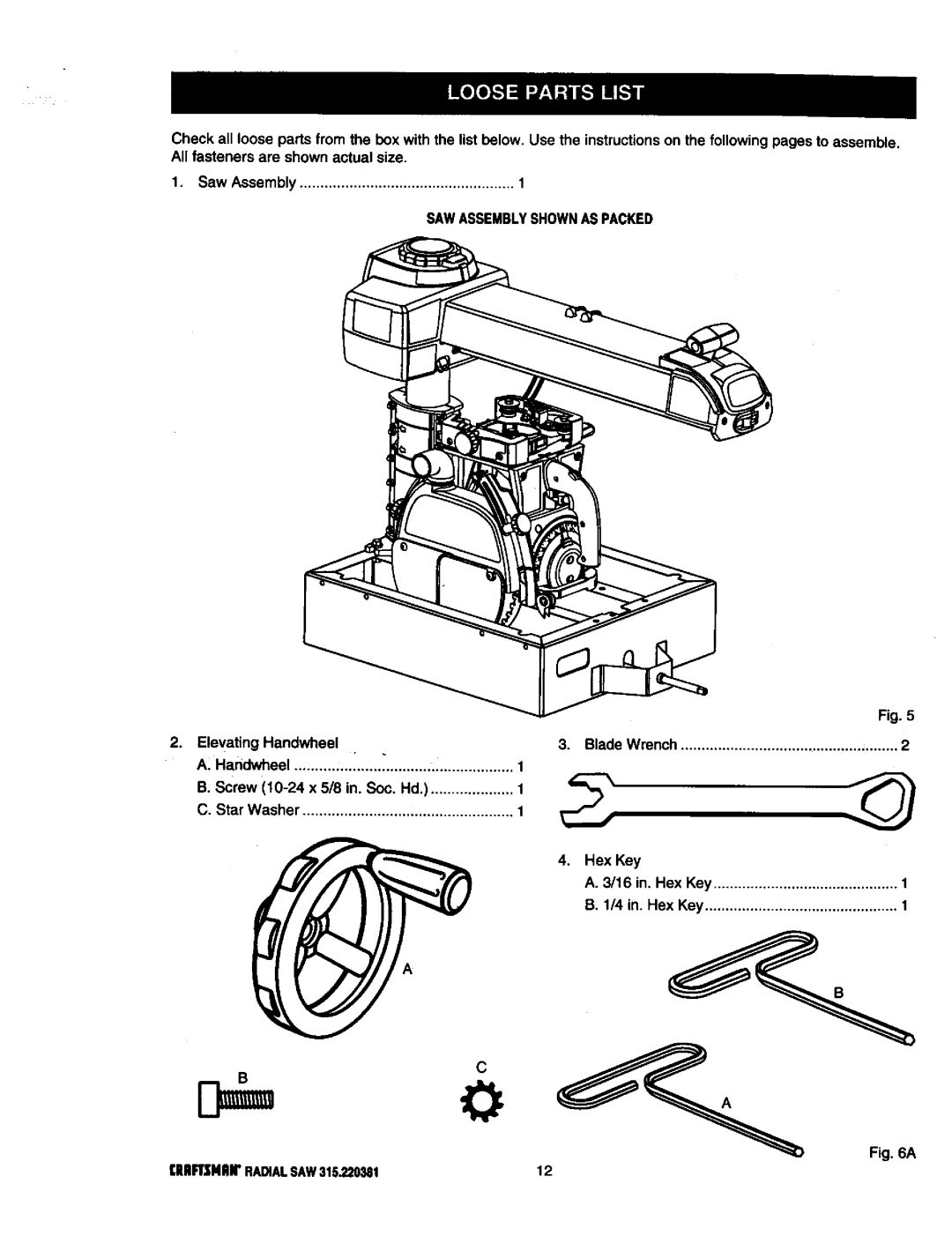

•REMOVE WRENCHES AND ADJUSTING KEYS. Get in the habit of checking - before turning on the tool - that hex keys and adjusting wrenches are removed from tool.

•CHECK DAMAGED PARTS. Before using the tool again, check any damaged parts, including guards, for proper operation and performance. Check alignment of moving parts, bindingof moving parts, breakage of parts, saw stability, mounting,and any other conditionsthat may affect its operation. A damaged part must be properly repaired or re- placed by a qualified service technician at a Sears repair center to avoid risk of personal injury.

•USE ONLY CORRECT BLADES. Use the right blade style for the material and the type of cut. Use only blades marked for at least 5,000 rpm and 10 in. or smaller, with a 5/8 in. arbor hole.

•KEEP GUARDS IN PLACE and in good working

order. This includes the blade guard, the riving knife, and the

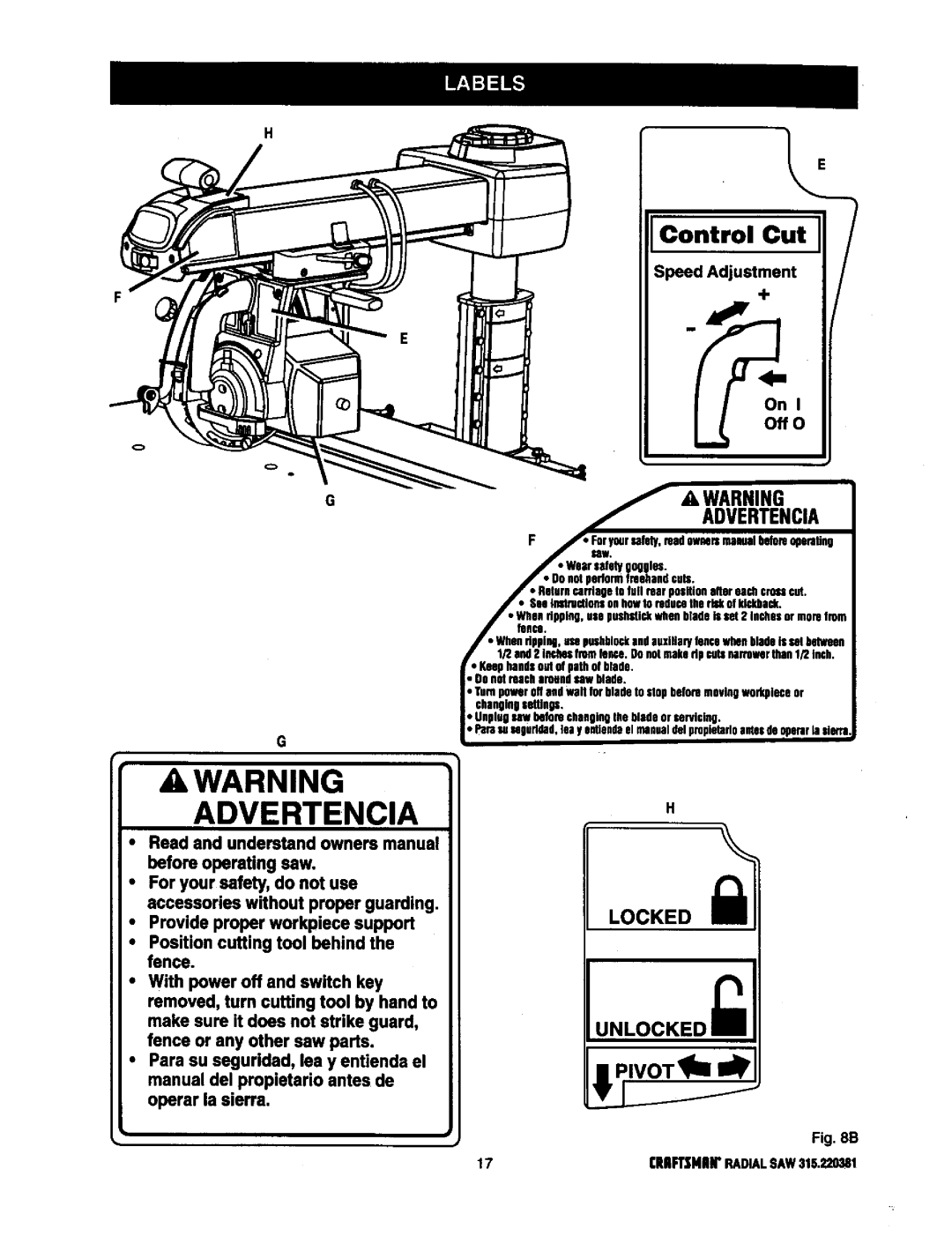

•CHECK DIRECTION OF FEED. When ripping, •

feed work into a blade or cutter against the direc- tion of rotationof the blade or cutter.

•NEVER LEAVE TOOL RUNNING UNA'I'rENDED. TURN THE POWER OFF. Do not leave the tool until it comes to a complete stop.

•USE RECOMMENDED ACCESSORIES. Using improper accessories may risk injury. Consult the Accessories section for recommended acceSso- ries.

•USE ONLY SEARS REPLACEMENT PARTS. All

repairs, whether electrical or mechanical, should be made by a qualified service technician at a Sears repair center.

DISCONNECT ALL TOOLS. When not in use, before servicing, or when changing attachments, blades, bits, cutters, etc., all tools should be disconnected from the power supply.

•DO NOT FORCE THE TOOL. It will do the job better and moresafely at the rate for which it was designed.

•BEFORE MOUNTING, DISCONNECTING OR REMOUNTING THE MOTOR; unplug the saw and remove the switch key.

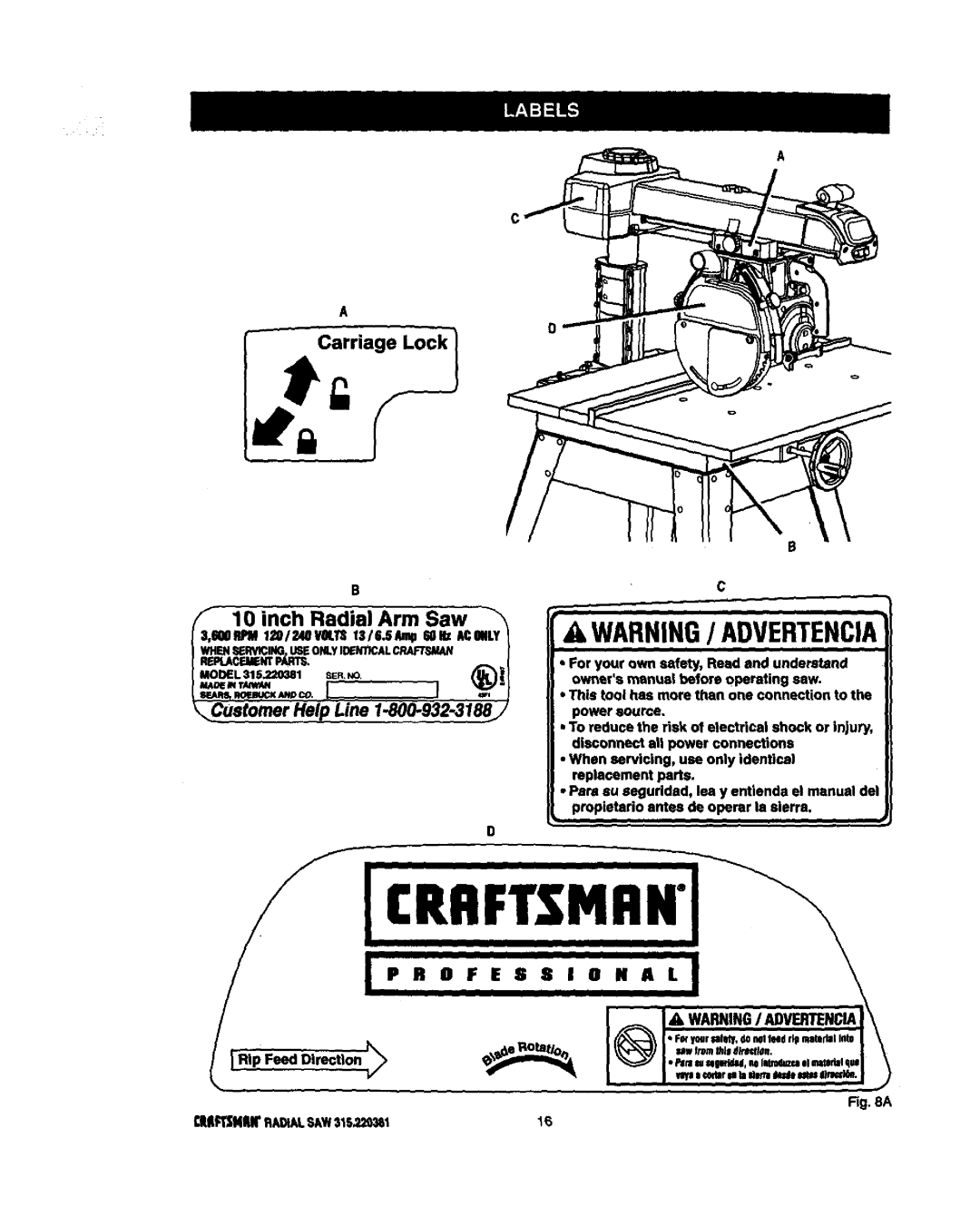

_l, WARNING: When servicing, use only identical

Craftsman replacement pads. Use of any other parts may create a hazard or damage product.

•NEVER USE THIS TOOL IN AN EXPLOSIVE ATMOSPHERE. Normal sparking of the motor could ignite fumes.

•MAKE SURE THE WORK AREA HAS AMPLE LIGHTING to see the work and that no obstruc- tions will interfere with safe operation BEFORE performing any work using this tool.

•DO NOT USE TOOL IF SWITCH DOES NOT TURN IT ON AND OFF. Have defective switches replaced by a qualified service technician at a

Sears repair center.

•GUARD AGAINST ELECTRICAL SHOCK by preventing body contact with grounded surfaces

such as pipes, radiators, ranges, refrigerator enclosures.

•GROUND ALL TOOLS. See Electrical page.

•WEAR A DUST MASK to keep from inhaling fine particles. Use wood dust collection systems whenever possible.

•PROTECT YOUR HEARING. Wear hearing protectionduring extended periods of operation.

•DO NOT OPERATE THIS TOOL WHILE UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR ANY MEDICATION.

STAY ALERT AND EXERCISE CONTROL. Watch what you are doing and use common sense. Do not operate tool when you are tired. Do not rush.

•AVOID AWKWARD OPERATIONS AND HAND

POSITIONS where a sudden slip could cause your hand to move into the blade, ALWAYS make sure

you have good balance•

5 | qlIIFt3NlUr RADIALSAW$15.220_t |