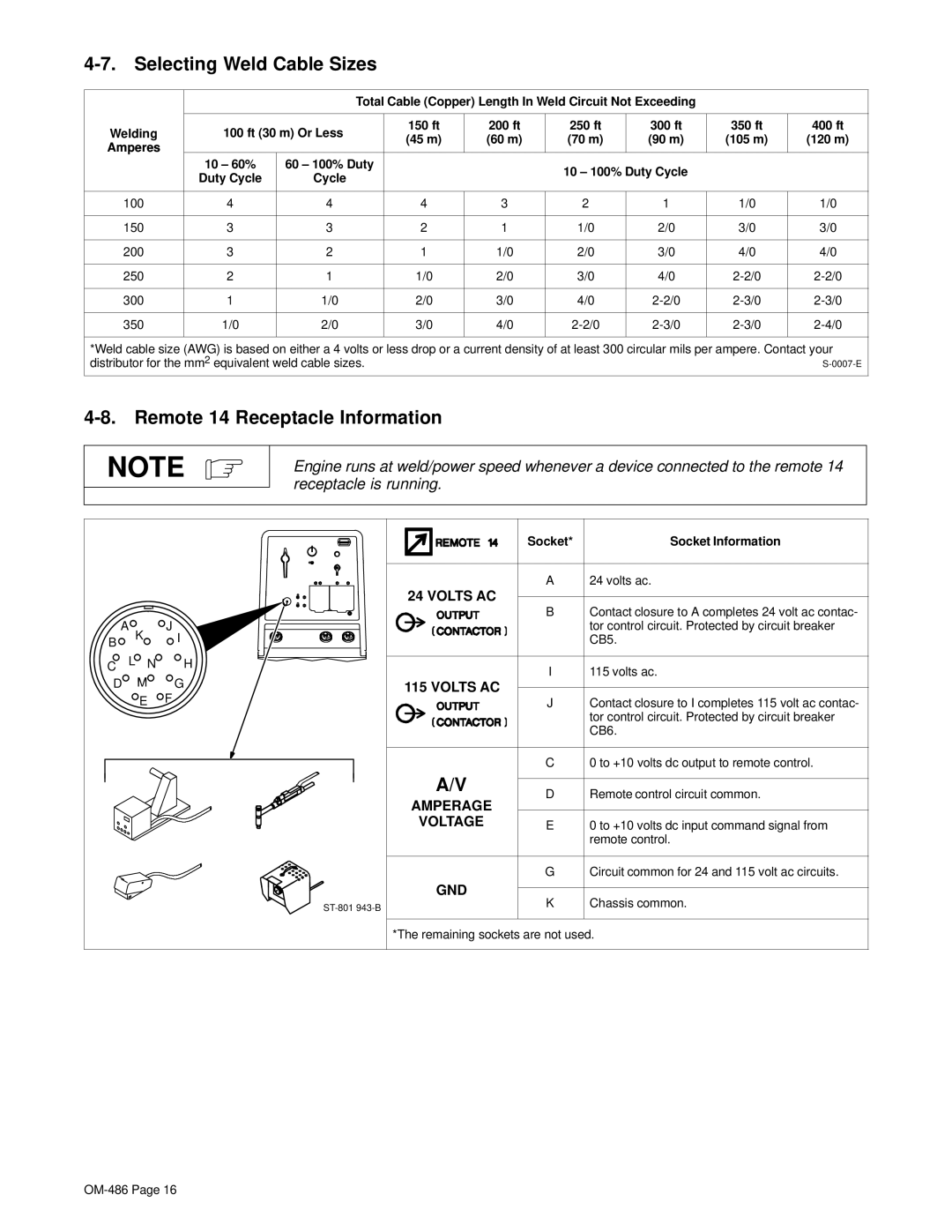

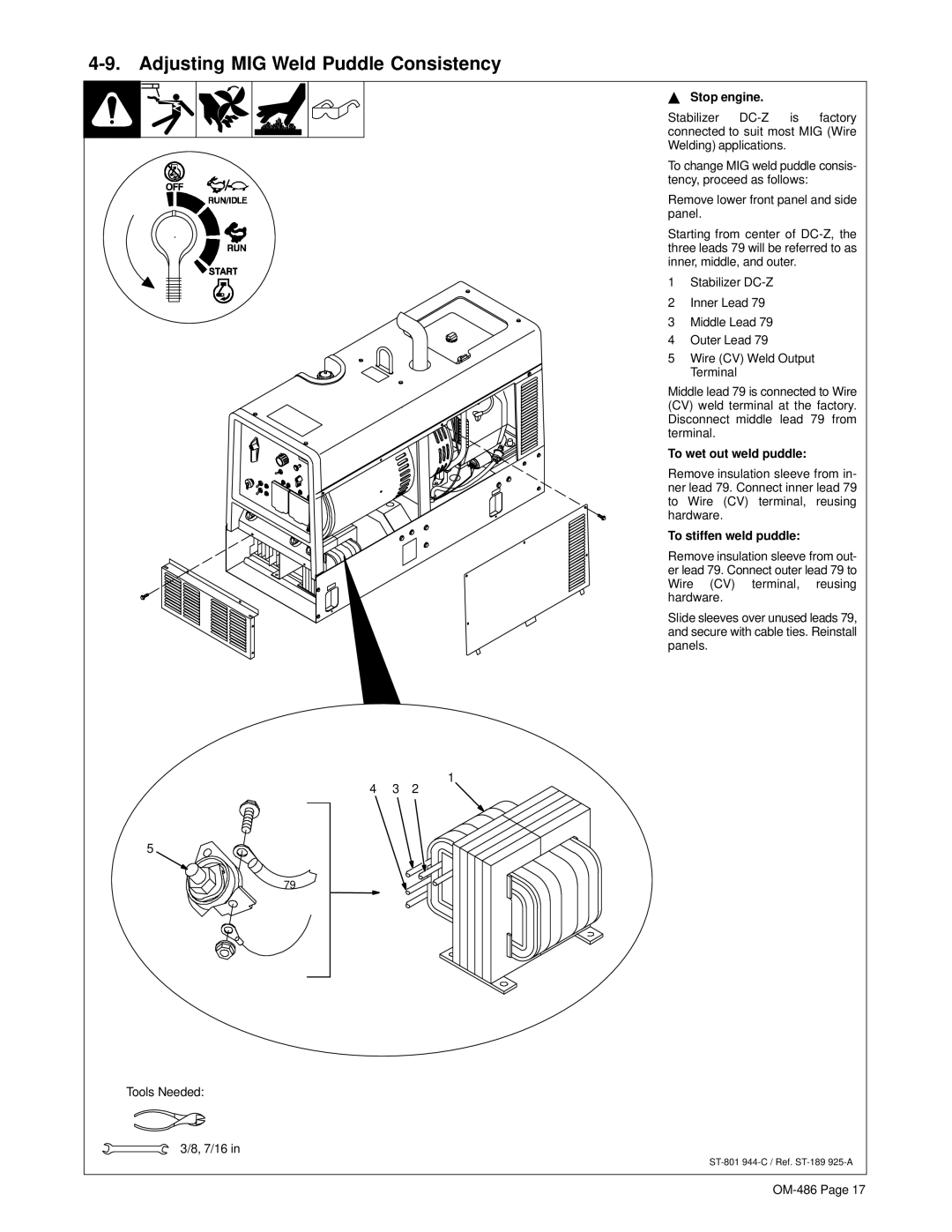

4-9. Adjusting MIG Weld Puddle Consistency

Y Stop engine.

Stabilizer

To change MIG weld puddle consis- tency, proceed as follows:

Remove lower front panel and side panel.

Starting from center of

1 Stabilizer

2 Inner Lead 79

3 Middle Lead 79

4 Outer Lead 79

5 Wire (CV) Weld Output

Terminal

Middle lead 79 is connected to Wire (CV) weld terminal at the factory. Disconnect middle lead 79 from terminal.

To wet out weld puddle:

Remove insulation sleeve from in- ner lead 79. Connect inner lead 79 to Wire (CV) terminal, reusing hardware.

To stiffen weld puddle:

Remove insulation sleeve from out- er lead 79. Connect outer lead 79 to Wire (CV) terminal, reusing hardware.

Slide sleeves over unused leads 79, and secure with cable ties. Reinstall panels.

1

4 3 2

5

79

Tools Needed:

3/8, 7/16 in