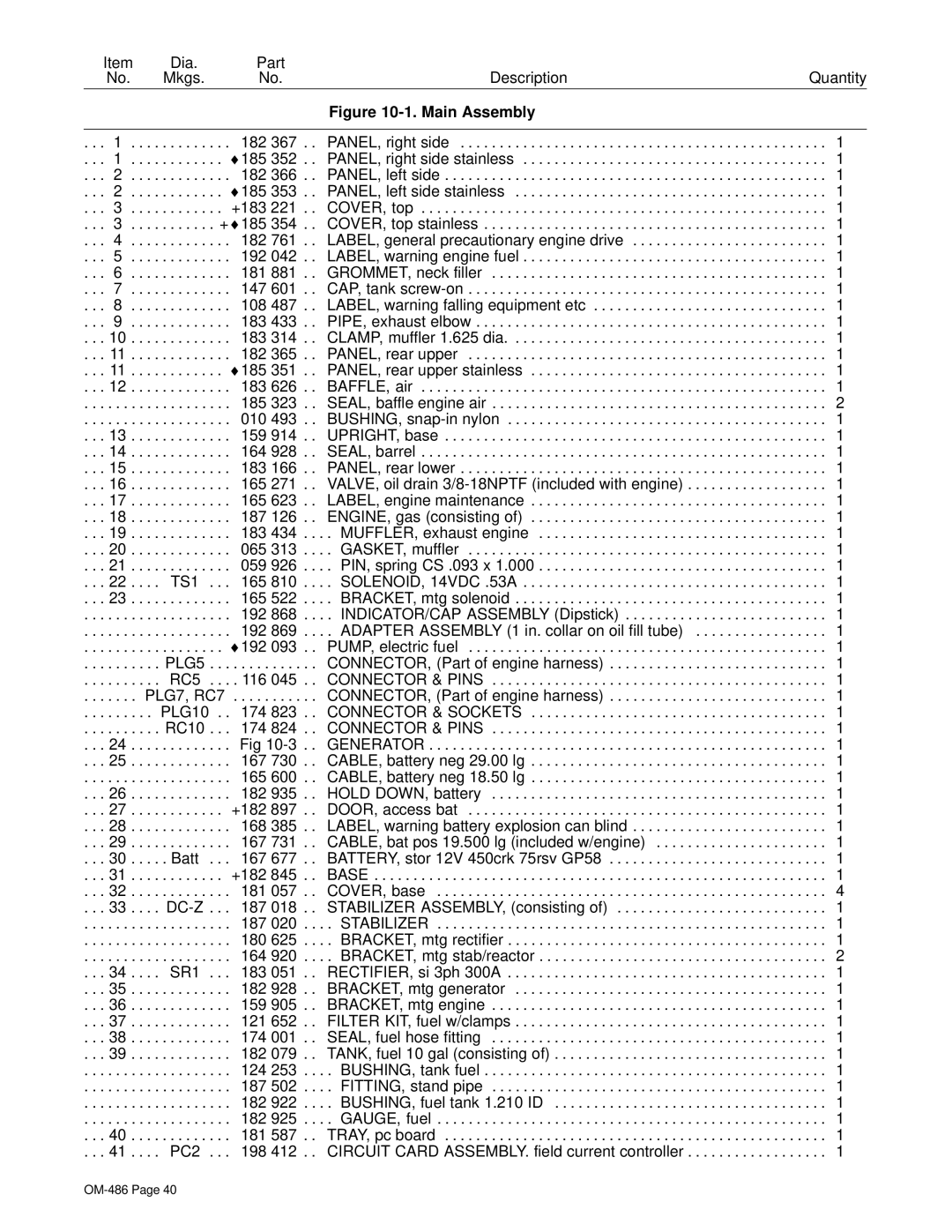

Item | Part | Description |

| |

| No. | No. | Quantity | |

|

|

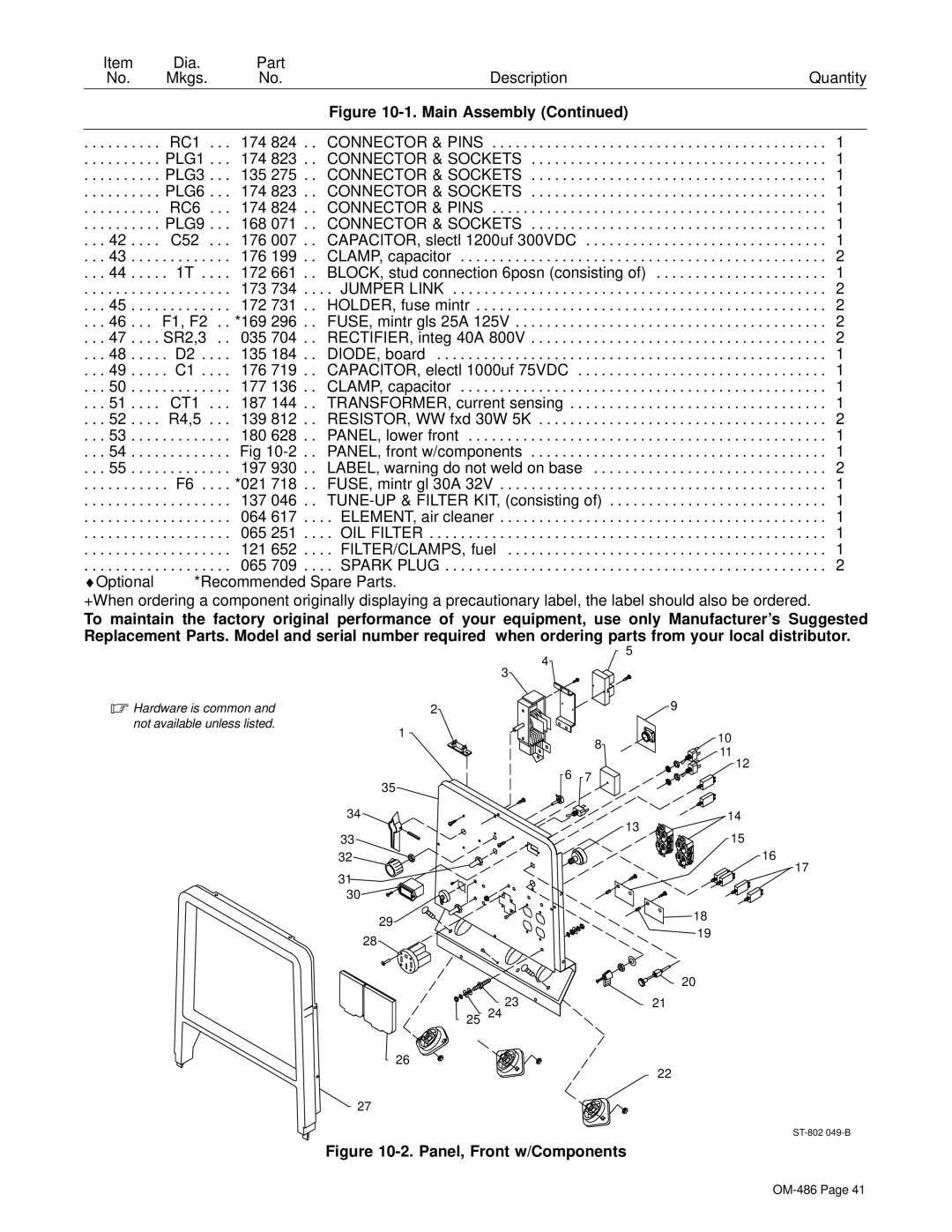

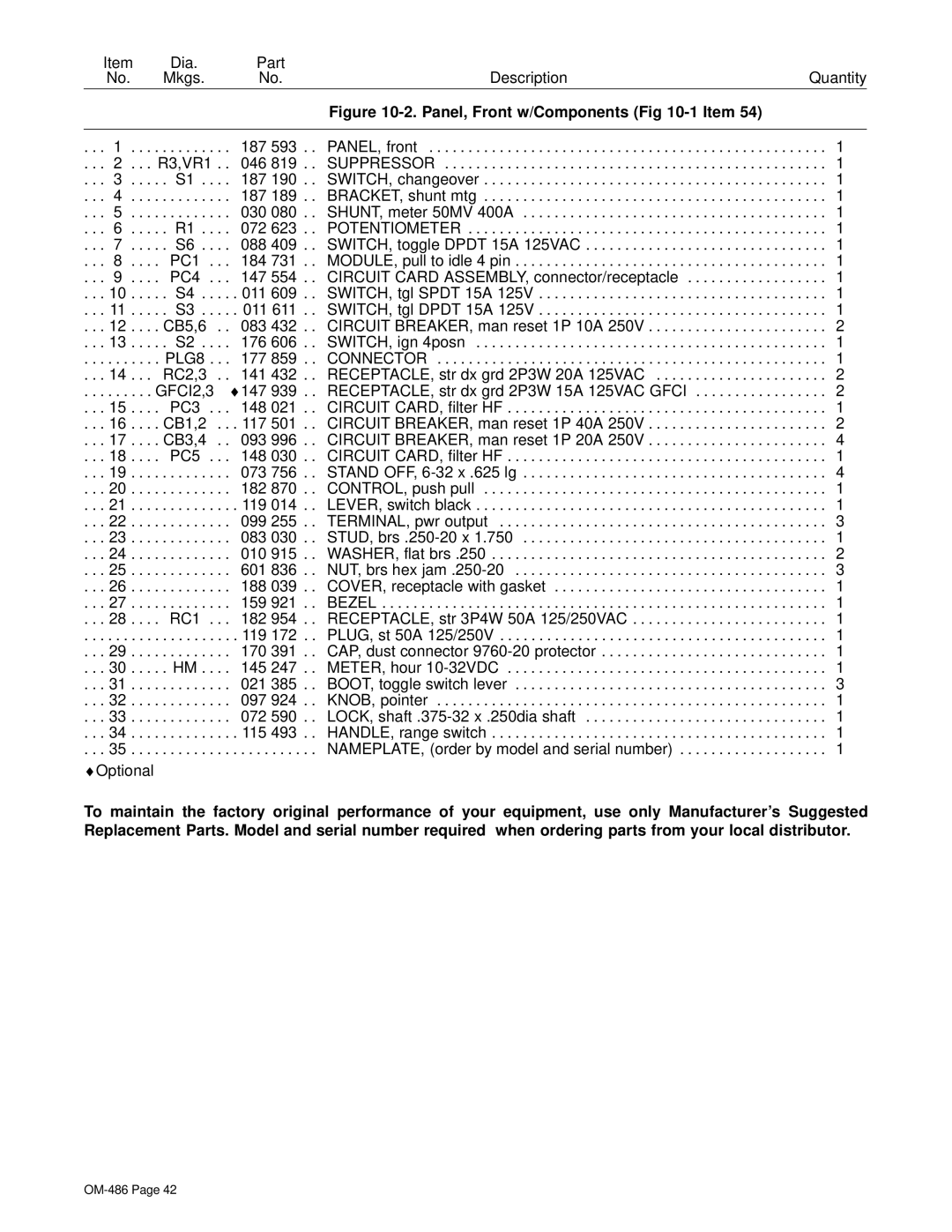

| Figure |

|

|

|

|

| |

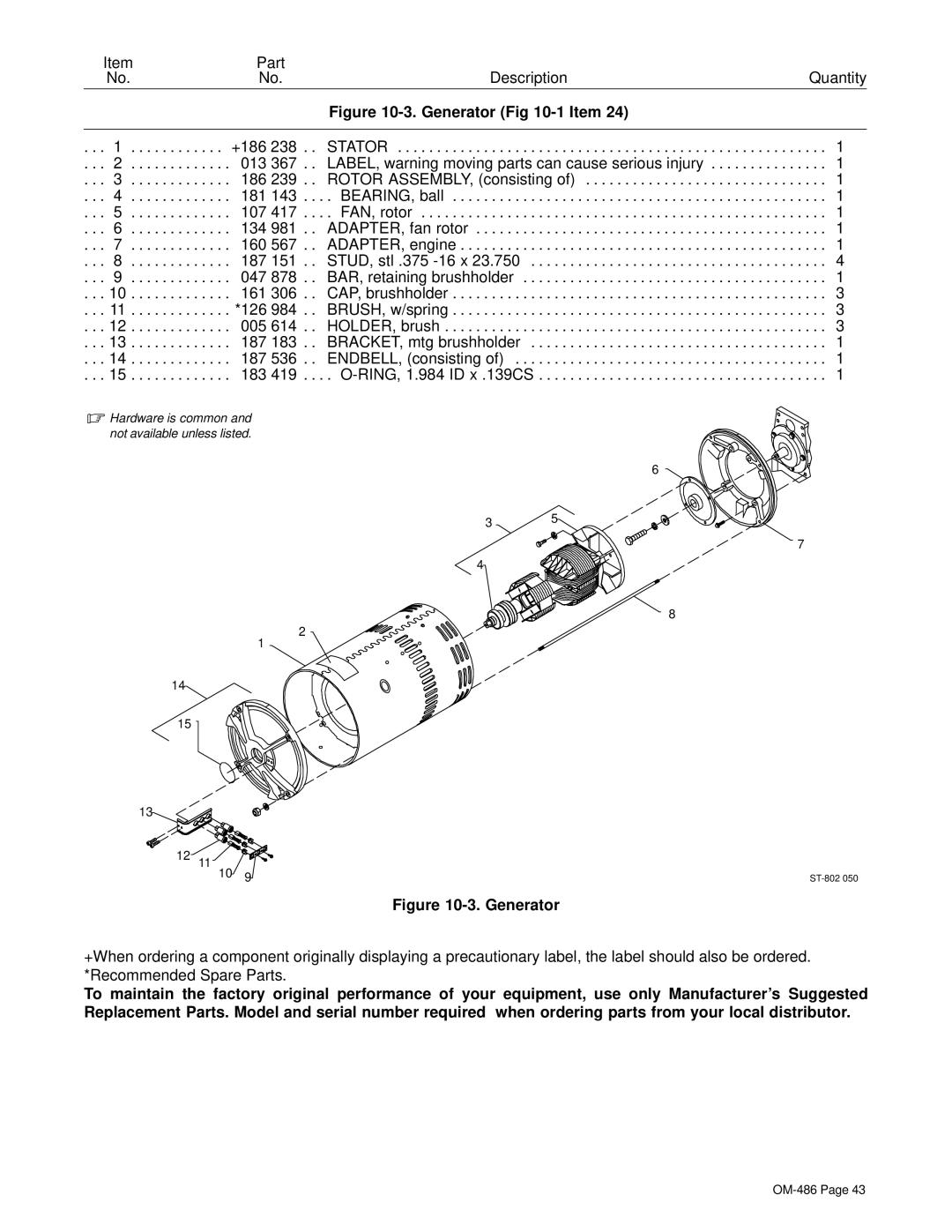

. . . 1 | +186 238 . . | STATOR | . . . 1 | |

. . . | 2 | 013 367 . . | LABEL, warning moving parts can cause serious injury | . . . 1 |

. . . | 3 | 186 239 . . | ROTOR ASSEMBLY, (consisting of) | . . . 1 |

. . . | 4 | 181 143 . . . | . BEARING, ball | . . . 1 |

. . . | 5 | 107 417 . . . | . FAN, rotor | . . . 1 |

. . . | 6 | 134 981 . . | ADAPTER, fan rotor | . . . 1 |

. . . | 7 | 160 567 . . | ADAPTER, engine | . . . 1 |

. . . | 8 | 187 151 . . | STUD, stl .375 | . . . 4 |

. . . | 9 | 047 878 . . | BAR, retaining brushholder | . . . 1 |

. . . 10 | 161 306 . . | CAP, brushholder | . . . 3 | |

. . . 11 | *126 984 . . | BRUSH, w/spring | . . . 3 | |

. . . 12 | 005 614 . . | HOLDER, brush | . . . 3 | |

. . . 13 | 187 183 . . | BRACKET, mtg brushholder | . . . 1 | |

. . . 14 | 187 536 . . | ENDBELL, (consisting of) | . . . 1 | |

. . . 15 | 183 419 . . . | . | . . . 1 | |

. Hardware is common and not available unless listed.

6 ![]()

3 5![]()

![]()

![]()

![]() 7 4

7 4![]()

8

2

1

14

15

13

12 | 11 |

|

|

| 10 | 9 | |

|

|

Figure 10-3. Generator

+When ordering a component originally displaying a precautionary label, the label should also be ordered. *Recommended Spare Parts.

To maintain the factory original performance of your Replacement Parts. Model and serial number required

equipment, use only Manufacturer’s Suggested when ordering parts from your local distributor.