FBKR18 Series, FBCR18 specifications

The Frymaster FBKR18 and FBCR18 series are among the industry’s leading commercial fryers, designed to meet the rigorous demands of high-volume food service operations. These advanced fryers are built to provide exceptional frying performance, energy efficiency, and ease of use, making them ideal for restaurants, cafeterias, and catering operations.One of the standout features of the Frymaster FBKR18 and FBCR18 series is their innovative cooking technology. These fryers incorporate the patented Frymaster oil management system, which helps to improve oil life while ensuring consistent food quality. The system includes an advanced filtration mechanism that can be operated manually or automatically, allowing for quick and efficient oil changes while minimizing downtime.

Another key characteristic of the FBKR18 and FBCR18 series is their impressive capacity. With the ability to hold up to 18 pounds of oil, these fryers can accommodate large batches of food, making them perfect for busy kitchens. The fryers come equipped with dual fry pots, allowing operators to prepare multiple menu items simultaneously without flavor transfer.

Energy efficiency is also a critical aspect of the Frymaster FBKR18 and FBCR18 series. These fryers utilize a high-efficiency burner design that reduces energy consumption while still delivering sufficient cooking power. This feature not only helps to lower utility costs but also contributes to a more environmentally friendly operation.

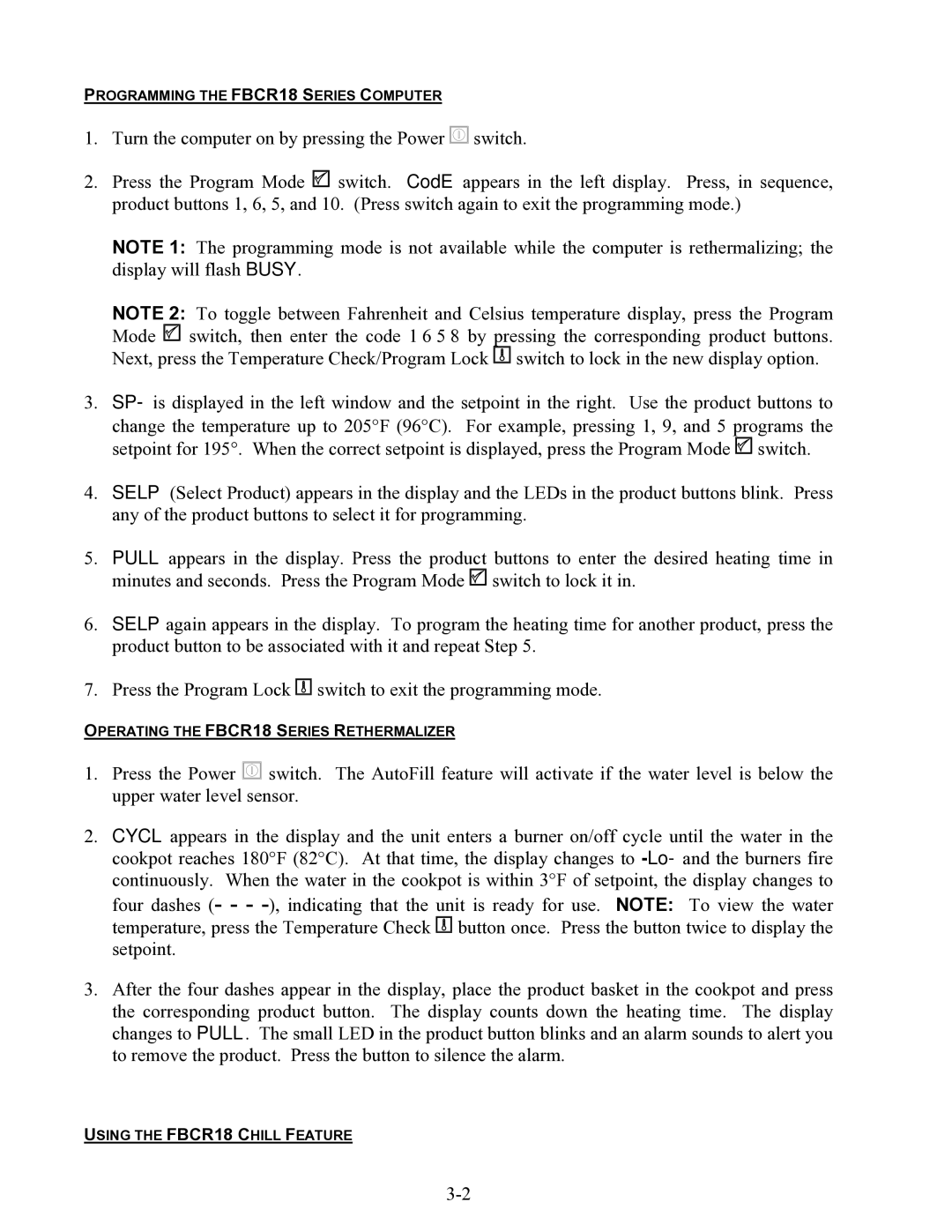

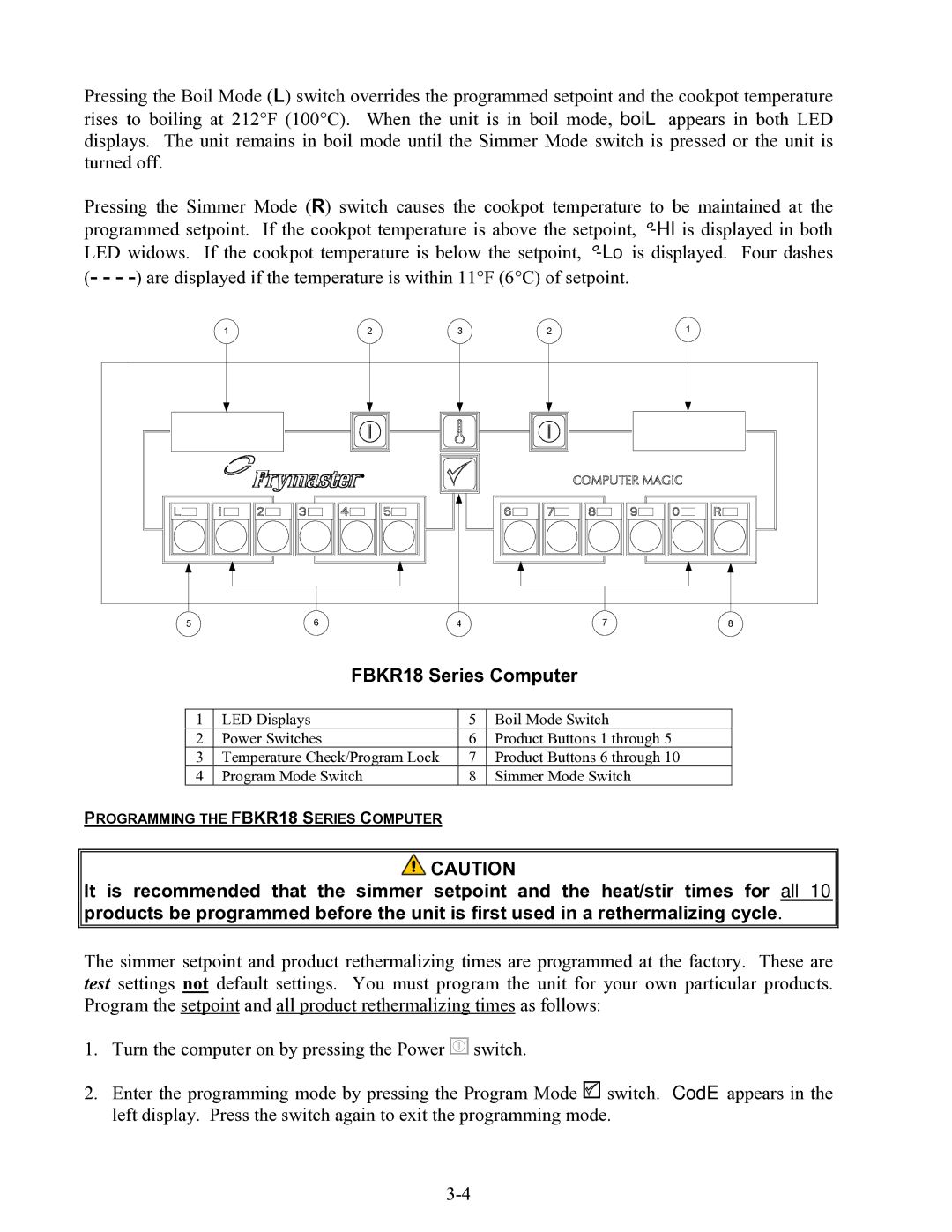

The design of the FBKR18 and FBCR18 series is focused on ease of use and safety. The fryers feature a user-friendly digital control panel that allows operators to easily monitor and adjust cooking temperatures. Additionally, the fryers are equipped with built-in safety features, such as automatic shut-off mechanisms, ensuring safe operation even in high-demand situations.

Durability is another hallmark of these fryers. Constructed from high-quality stainless steel, the FBKR18 and FBCR18 series are built to withstand the rigors of daily use in commercial kitchens. Their robust design not only ensures longevity but also simplifies cleaning and maintenance.

In summary, the Frymaster FBKR18 and FBCR18 series fryers combine advanced cooking technology, impressive capacity, energy efficiency, and user-friendly design to meet the needs of busy food service operations. With their durability and high performance, these fryers stand out as excellent choices for chefs aiming to achieve culinary excellence.