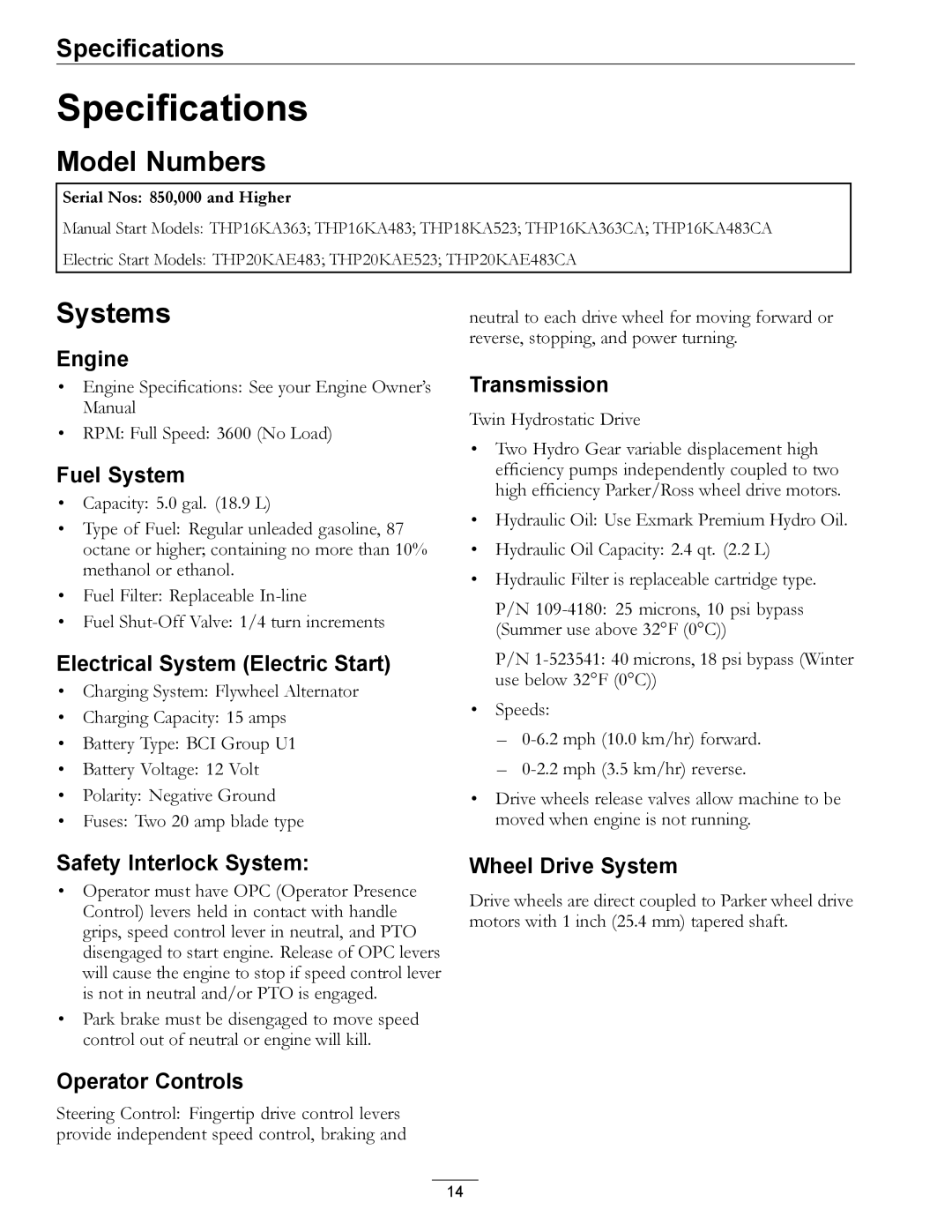

Operation

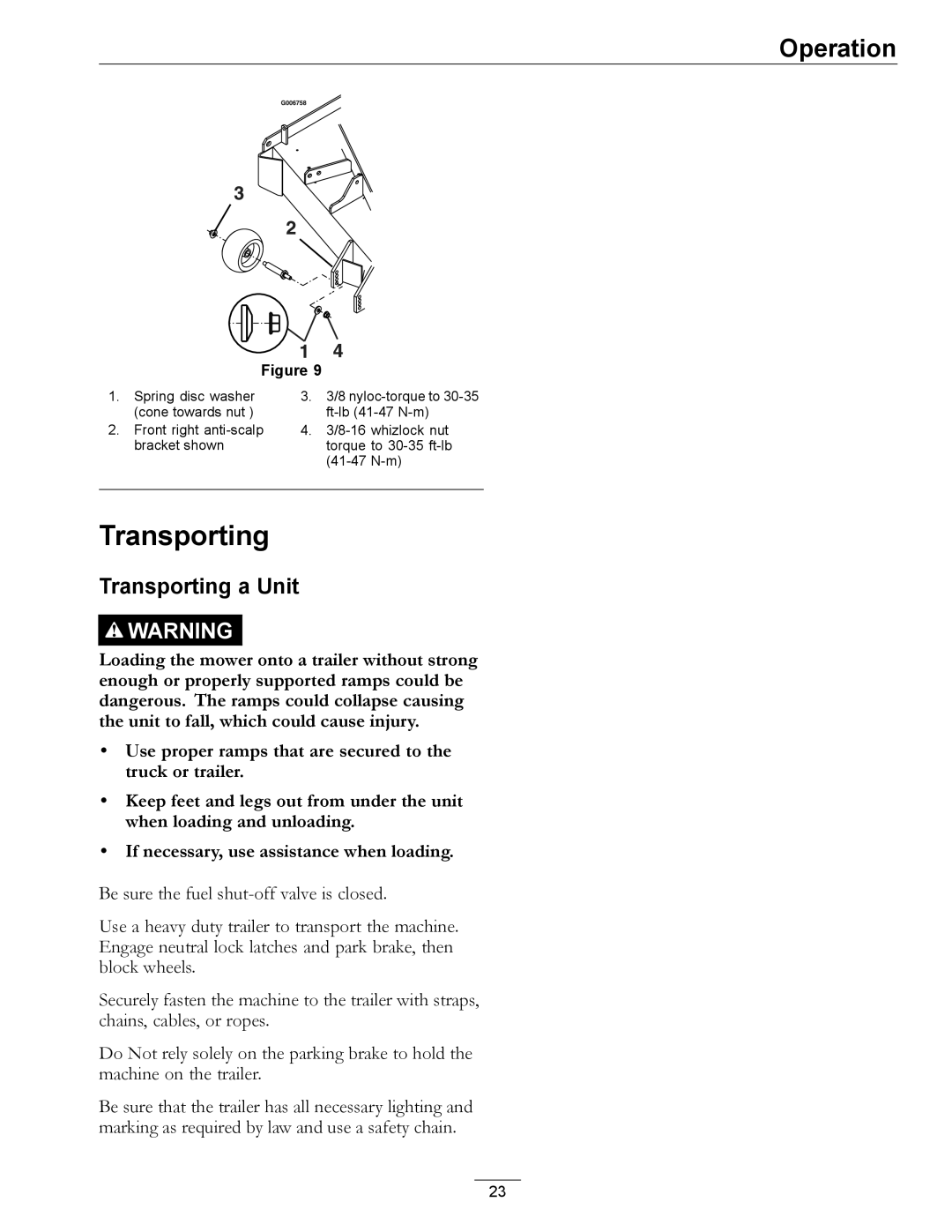

Figure 9

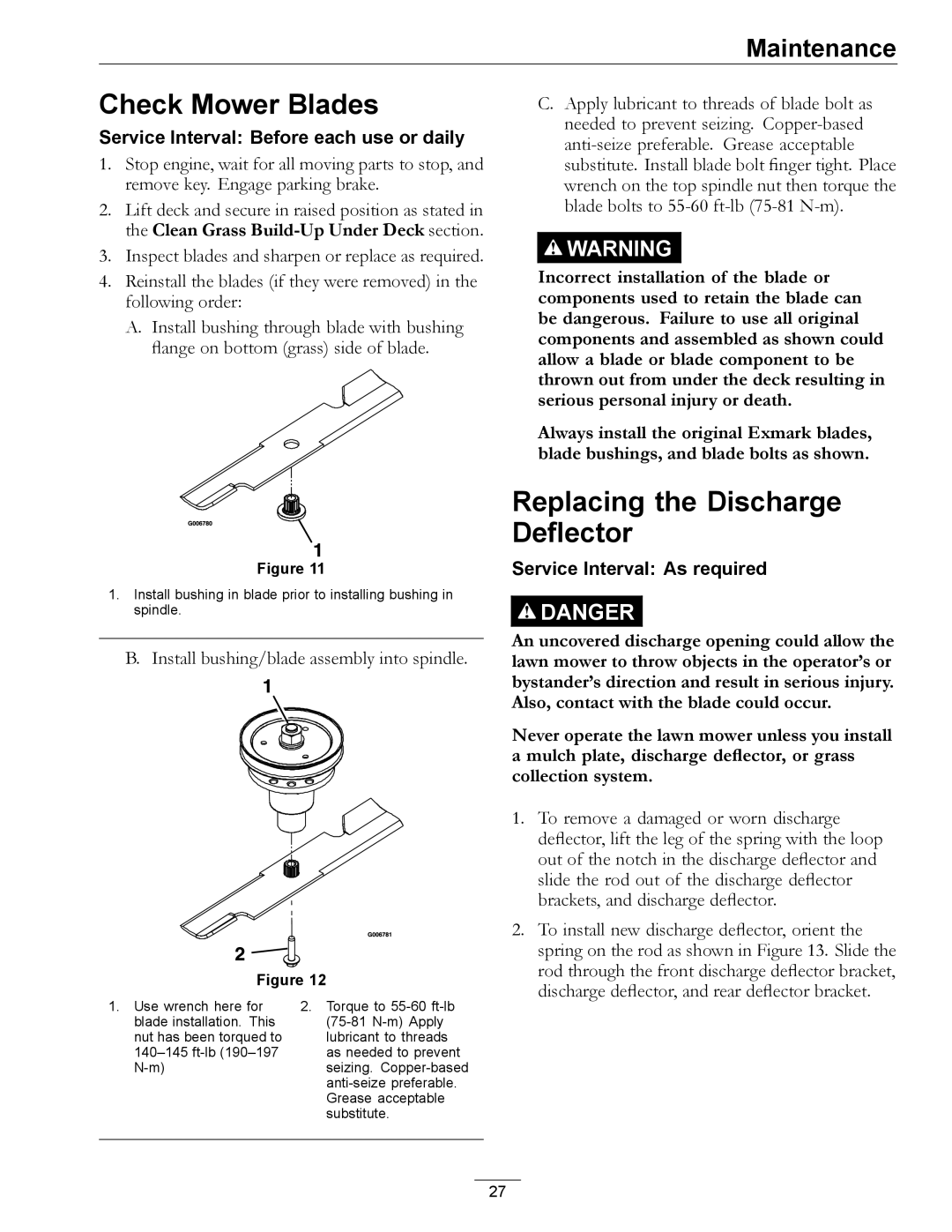

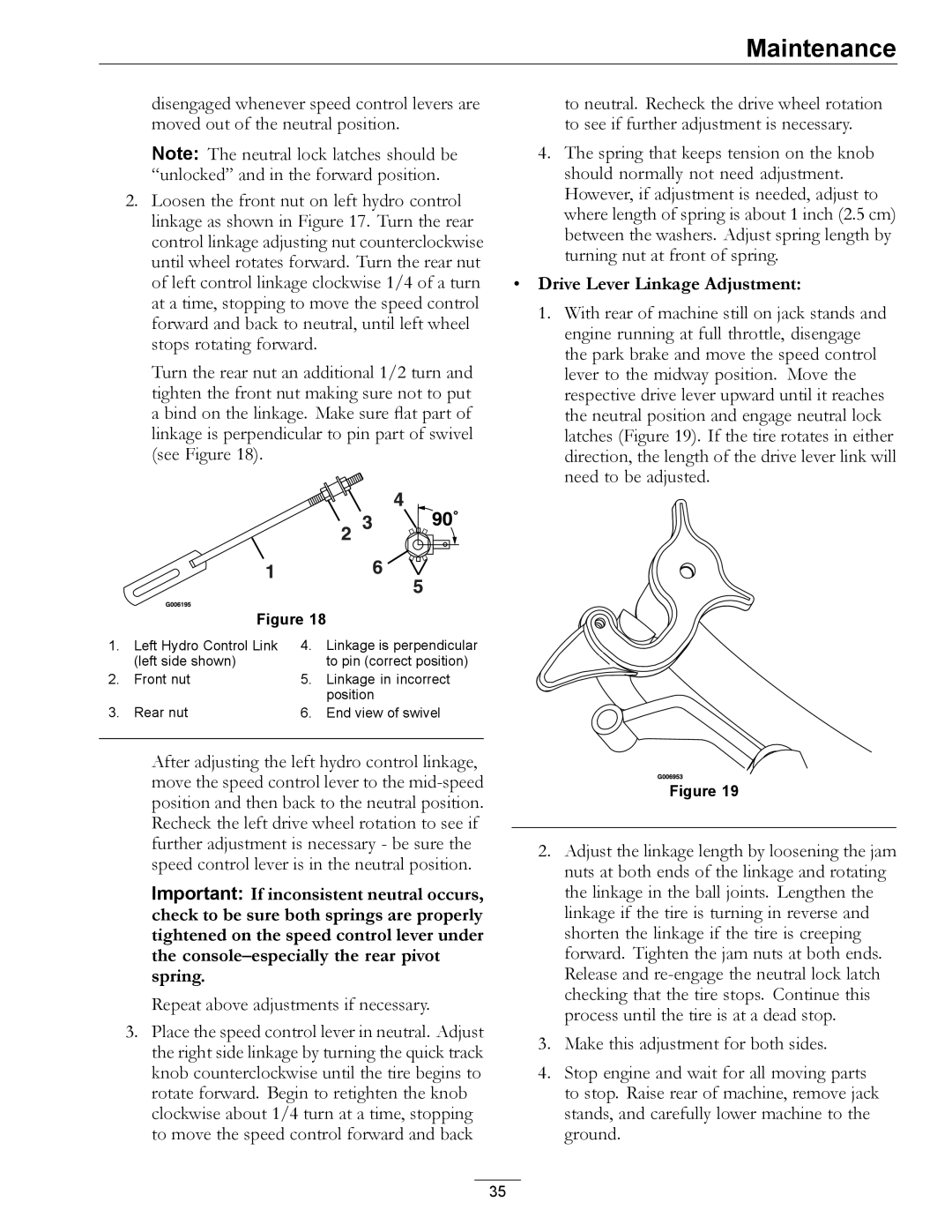

1. | Spring disc washer | 3. | 3/8 |

| (cone towards nut ) |

| |

2. | Front right | 4. | |

| bracket shown |

| torque to |

|

|

| |

|

|

|

|

Transporting

Transporting a Unit

![]()

![]() WARNING

WARNING

Loading the mower onto a trailer without strong enough or properly supported ramps could be dangerous. The ramps could collapse causing the unit to fall, which could cause injury.

•Use proper ramps that are secured to the truck or trailer.

•Keep feet and legs out from under the unit when loading and unloading.

•If necessary, use assistance when loading.

Be sure the fuel

Use a heavy duty trailer to transport the machine. Engage neutral lock latches and park brake, then block wheels.

Securely fasten the machine to the trailer with straps, chains, cables, or ropes.

Do Not rely solely on the parking brake to hold the machine on the trailer.

Be sure that the trailer has all necessary lighting and marking as required by law and use a safety chain.

23