Maintenance

Cleaning

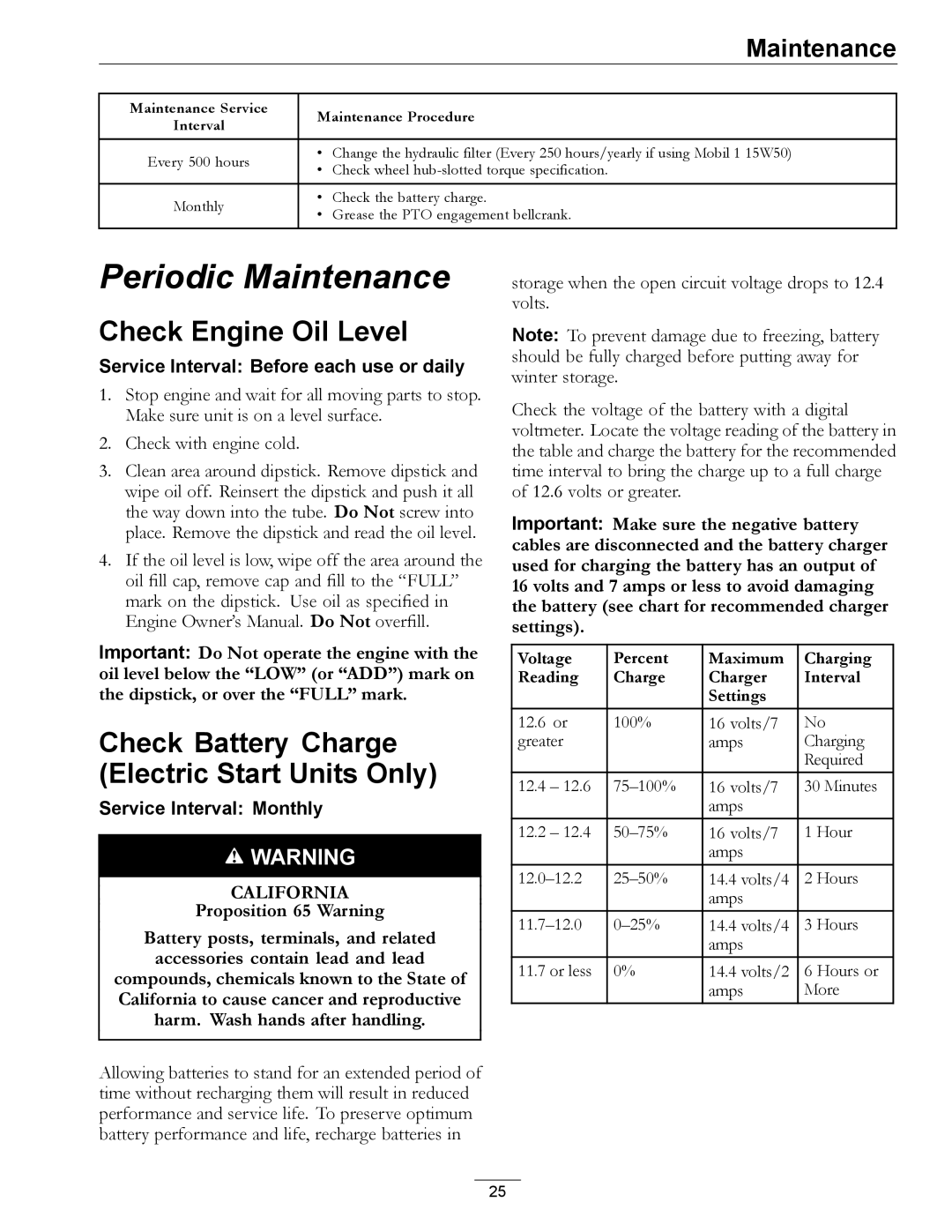

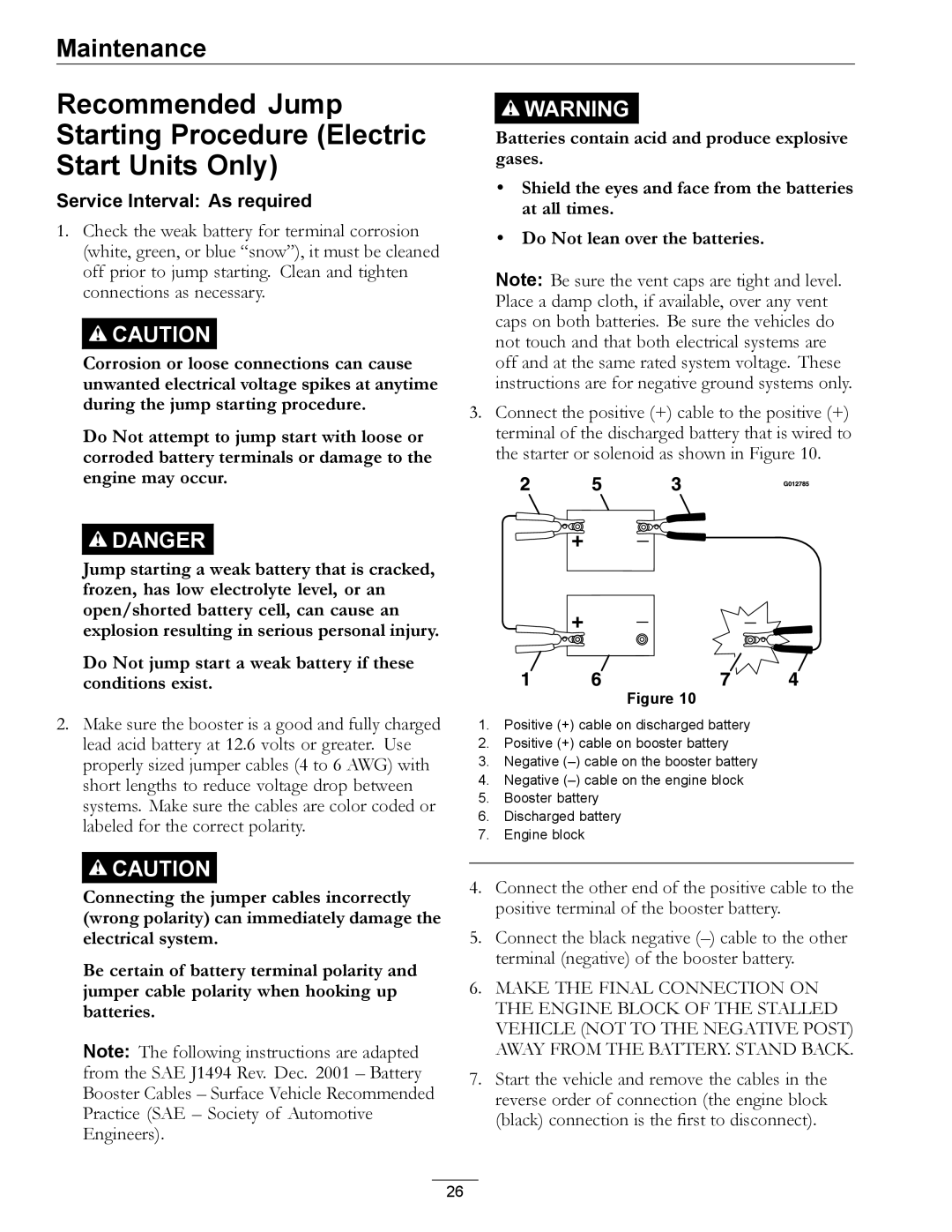

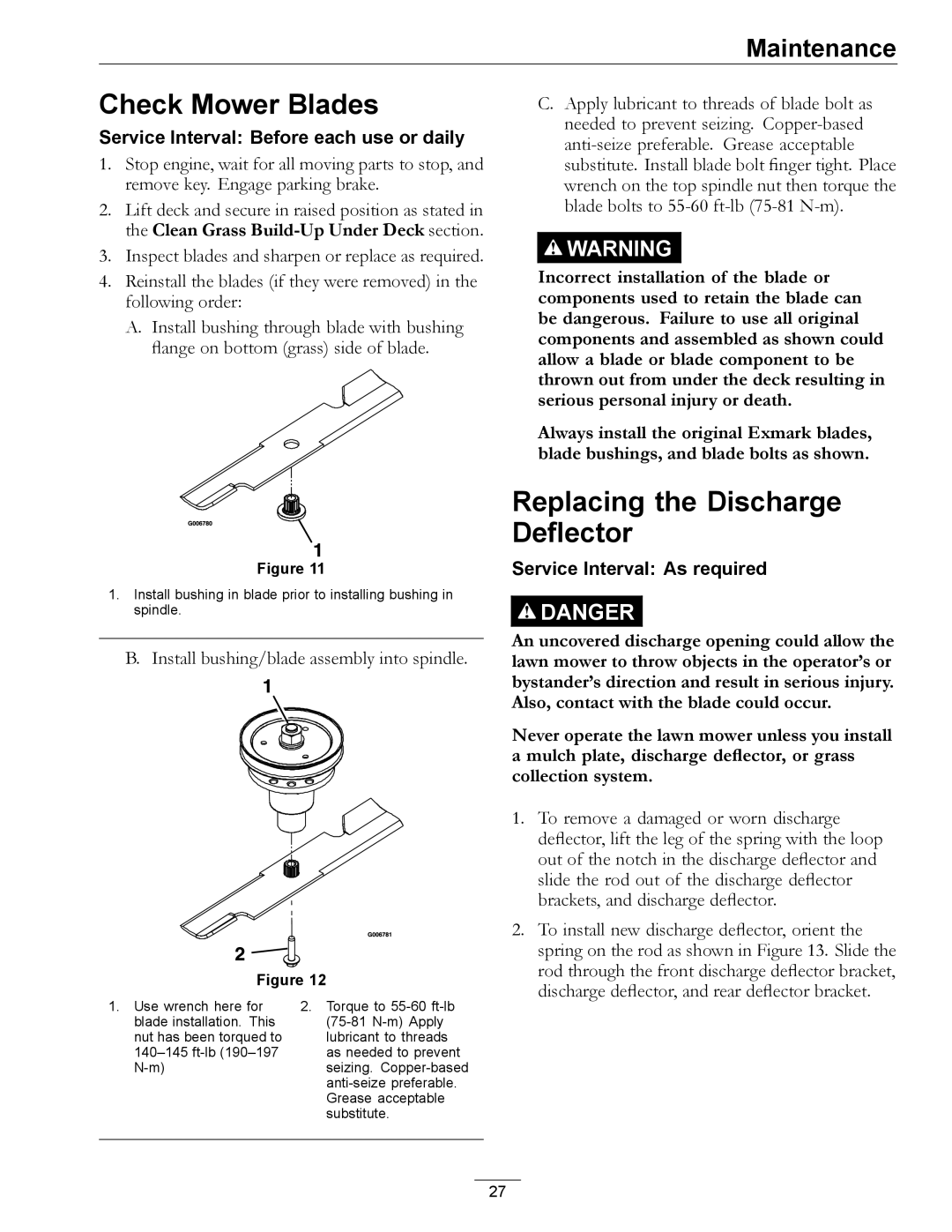

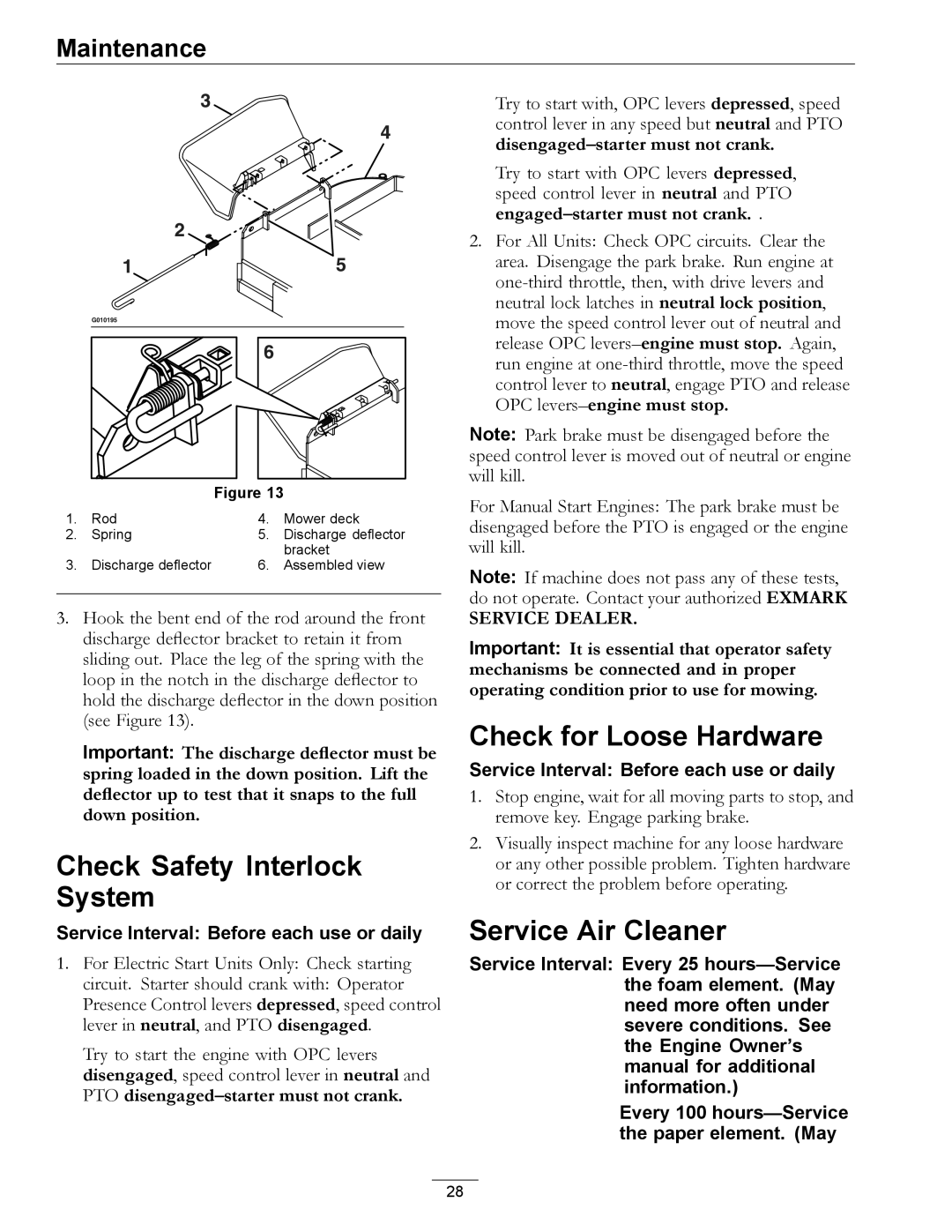

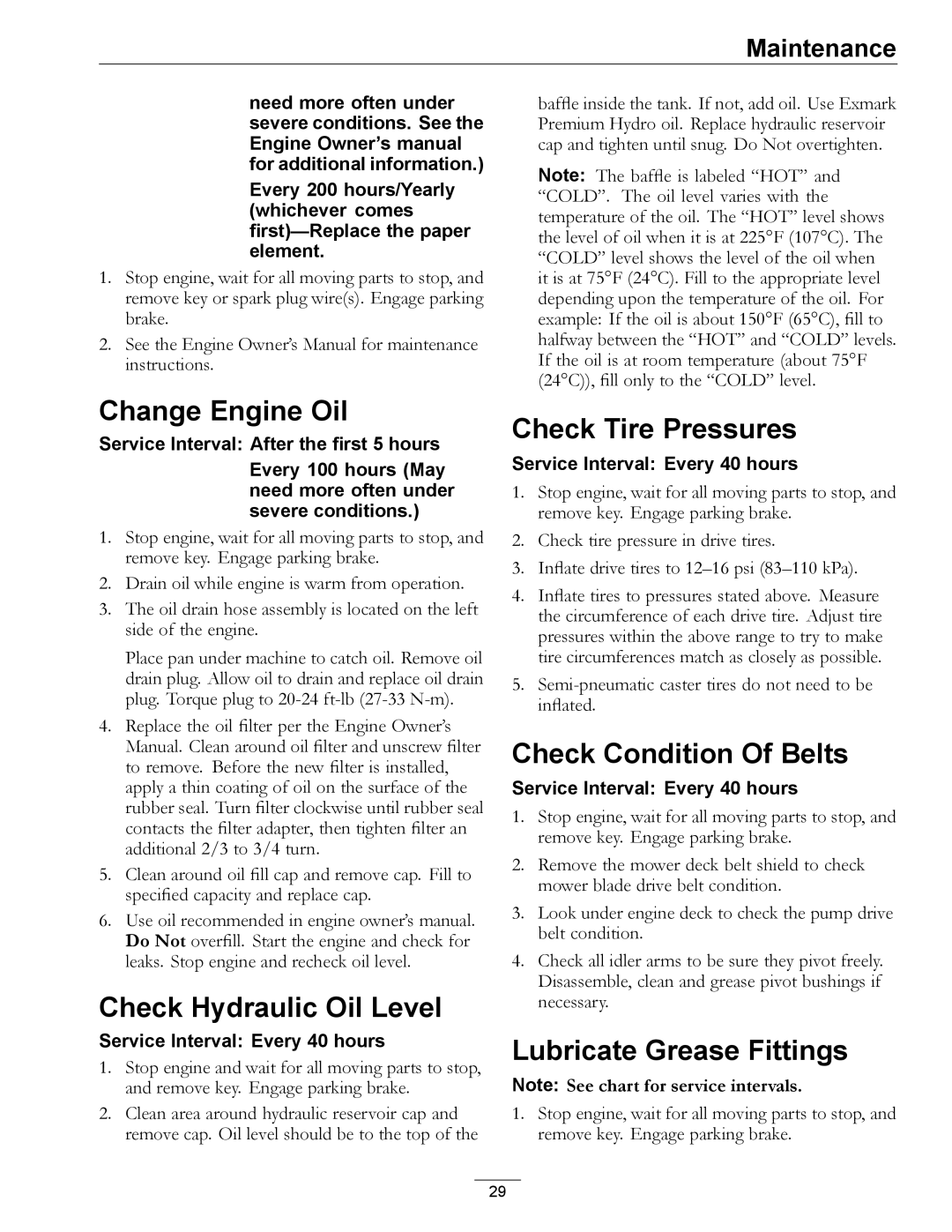

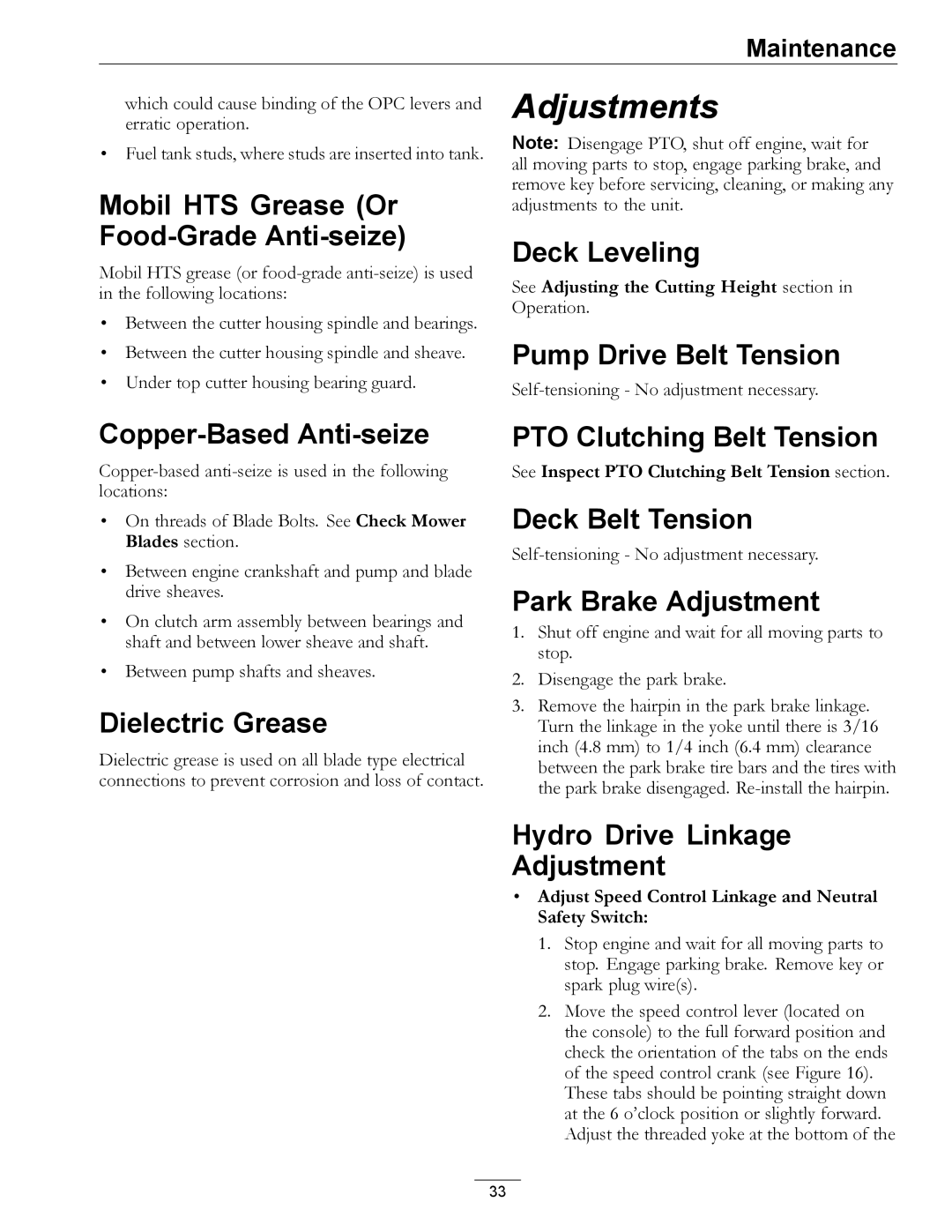

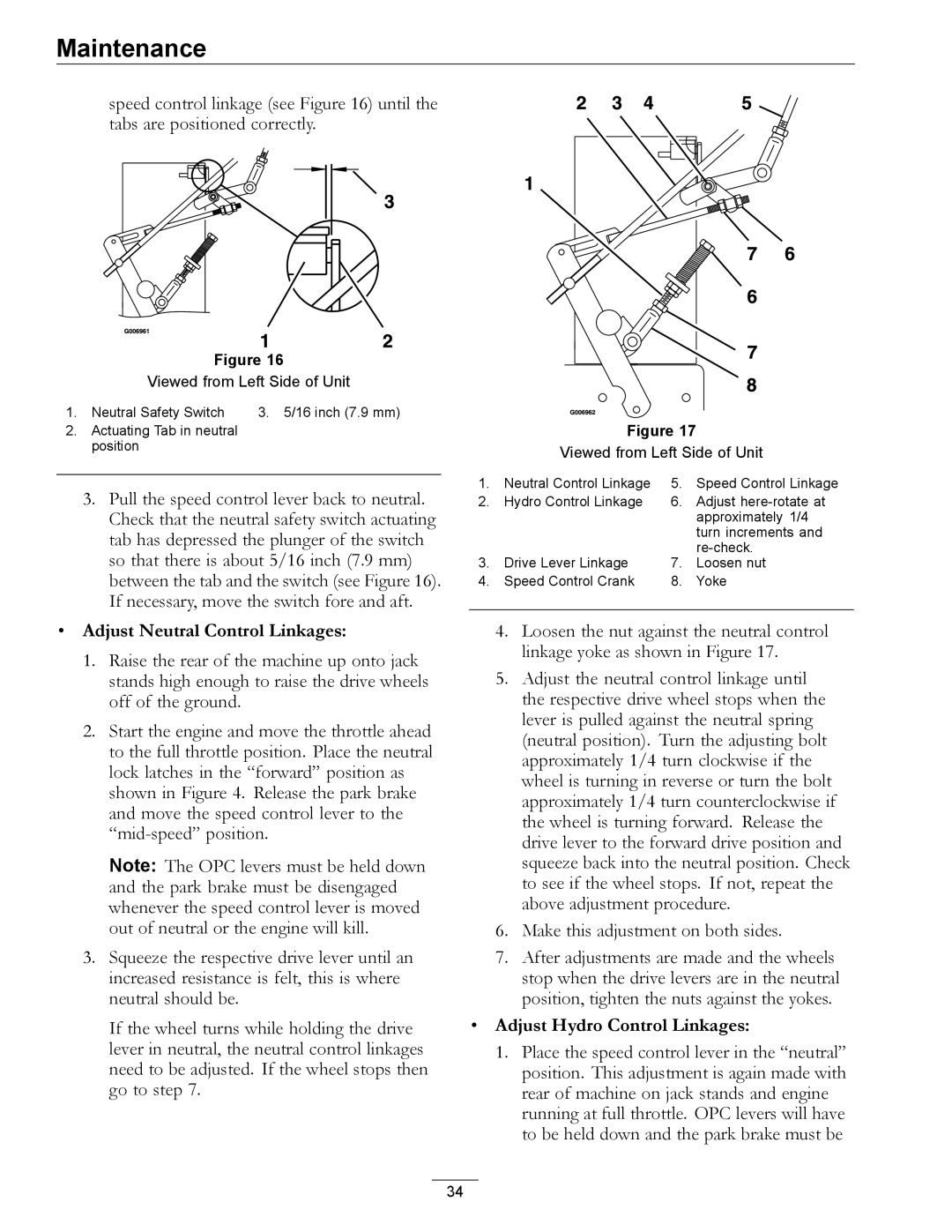

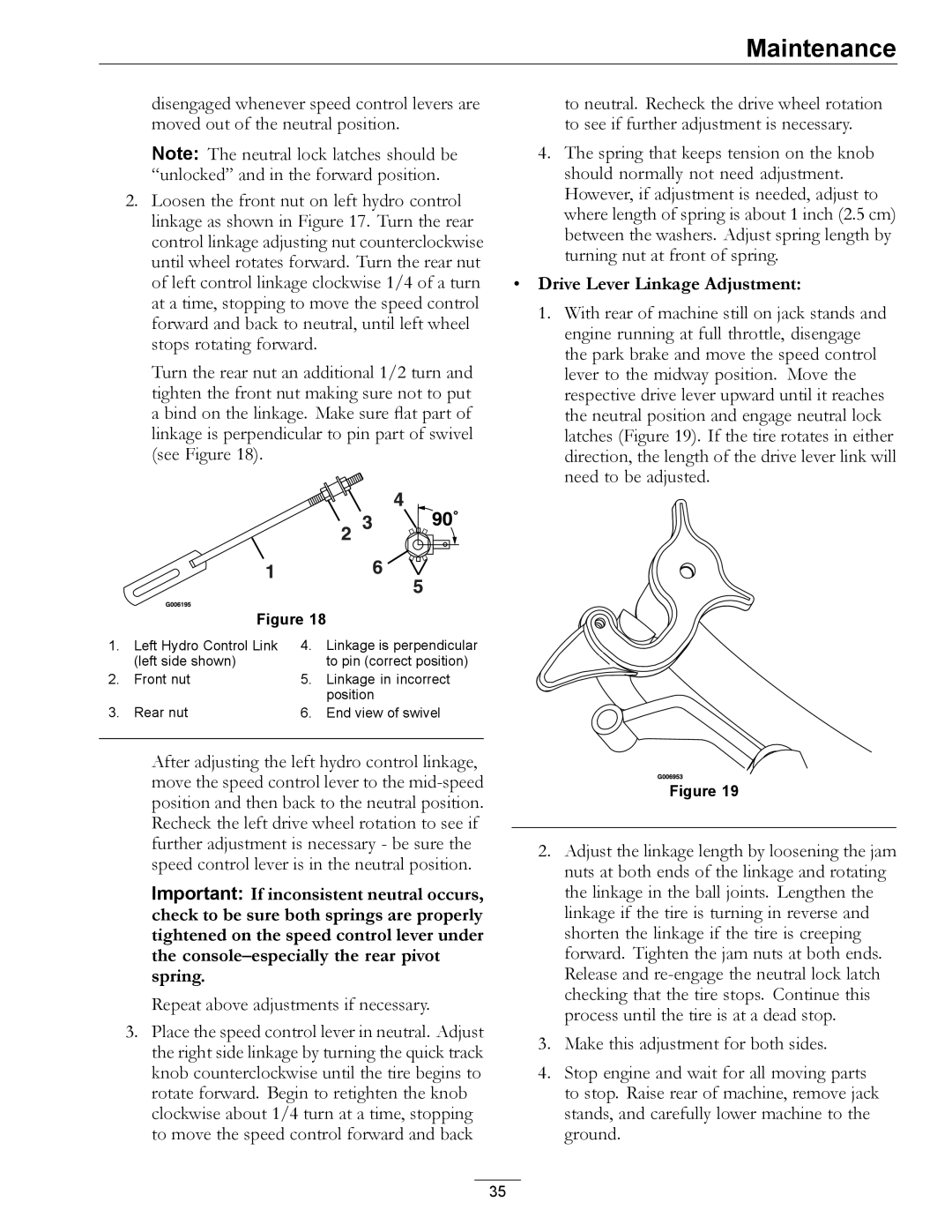

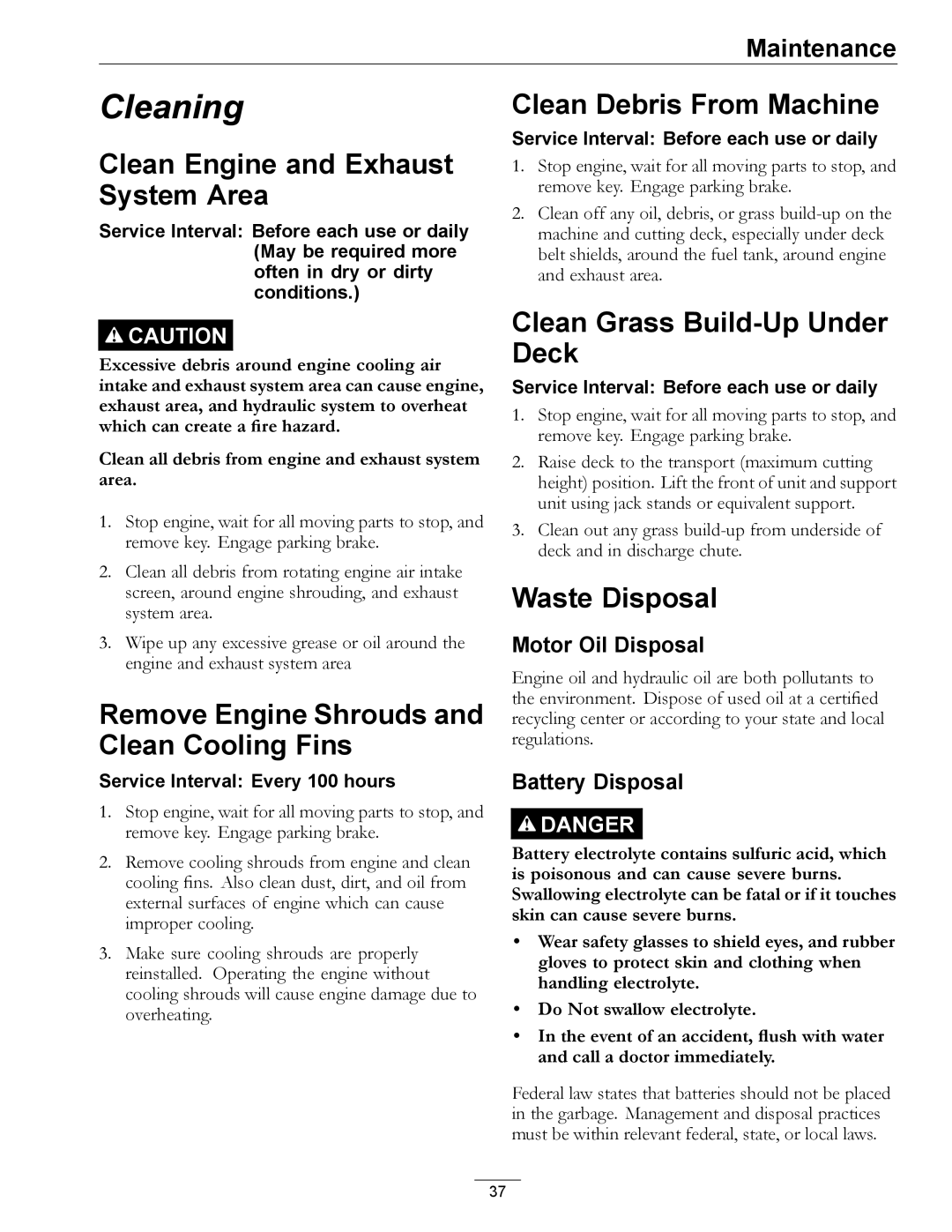

Clean Engine and Exhaust System Area

Service Interval: Before each use or daily (May be required more often in dry or dirty conditions.)

![]()

![]() CAUTION

CAUTION

Excessive debris around engine cooling air intake and exhaust system area can cause engine, exhaust area, and hydraulic system to overheat which can create a fire hazard.

Clean all debris from engine and exhaust system area.

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Clean all debris from rotating engine air intake screen, around engine shrouding, and exhaust system area.

3.Wipe up any excessive grease or oil around the engine and exhaust system area

Remove Engine Shrouds and Clean Cooling Fins

Service Interval: Every 100 hours

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Remove cooling shrouds from engine and clean cooling fins. Also clean dust, dirt, and oil from external surfaces of engine which can cause improper cooling.

3.Make sure cooling shrouds are properly reinstalled. Operating the engine without cooling shrouds will cause engine damage due to overheating.

Clean Debris From Machine

Service Interval: Before each use or daily

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Clean off any oil, debris, or grass

Clean Grass Build-Up Under Deck

Service Interval: Before each use or daily

1.Stop engine, wait for all moving parts to stop, and remove key. Engage parking brake.

2.Raise deck to the transport (maximum cutting height) position. Lift the front of unit and support unit using jack stands or equivalent support.

3.Clean out any grass

Waste Disposal

Motor Oil Disposal

Engine oil and hydraulic oil are both pollutants to the environment. Dispose of used oil at a certified recycling center or according to your state and local regulations.

Battery Disposal

![]()

![]() DANGER

DANGER

Battery electrolyte contains sulfuric acid, which is poisonous and can cause severe burns. Swallowing electrolyte can be fatal or if it touches skin can cause severe burns.

•Wear safety glasses to shield eyes, and rubber gloves to protect skin and clothing when handling electrolyte.

•Do Not swallow electrolyte.

•In the event of an accident, flush with water and call a doctor immediately.

Federal law states that batteries should not be placed in the garbage. Management and disposal practices must be within relevant federal, state, or local laws.

37