Maintenance

Tracking Adjustment

1.Stop engine and wait for all moving parts to stop.

2.Check the drive tire pressures and tire circumferences as stated in Check the Tire Pressures section in Maintenance.

3.Run the unit and observe the tracking on a level, smooth, hard surface such as concrete or asphalt.

4.If the unit tracks to one side or the other, turn the quick track knob. Turn the knob right to “steer” right, turn the knob left to “steer” left.

Hydro Pump Spring Tension Setting

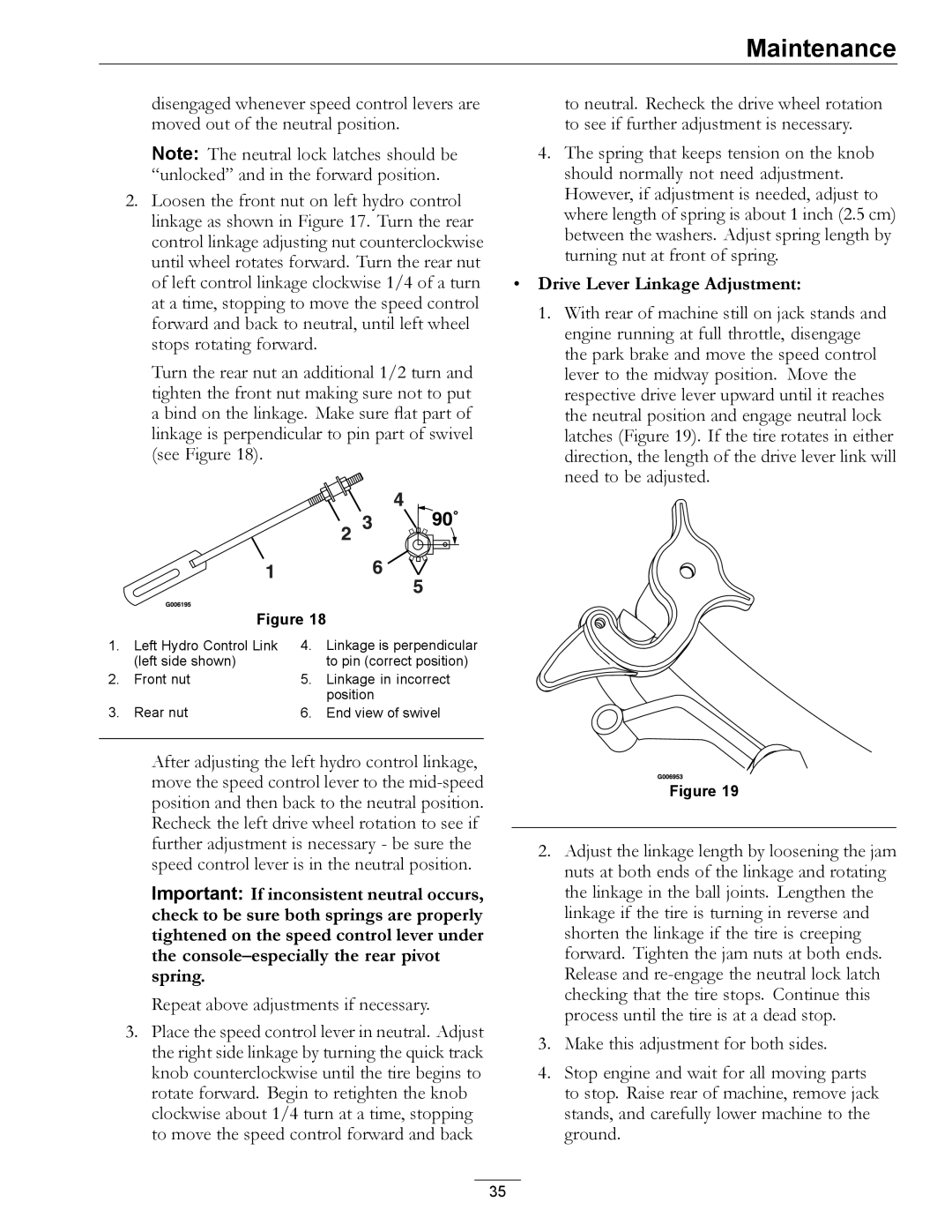

1.For medium or heavy duty drive conditions such as operation with a sulky on steep slopes, a higher spring force may be required on the hydro pump control arms to prevent the drive system from stalling.

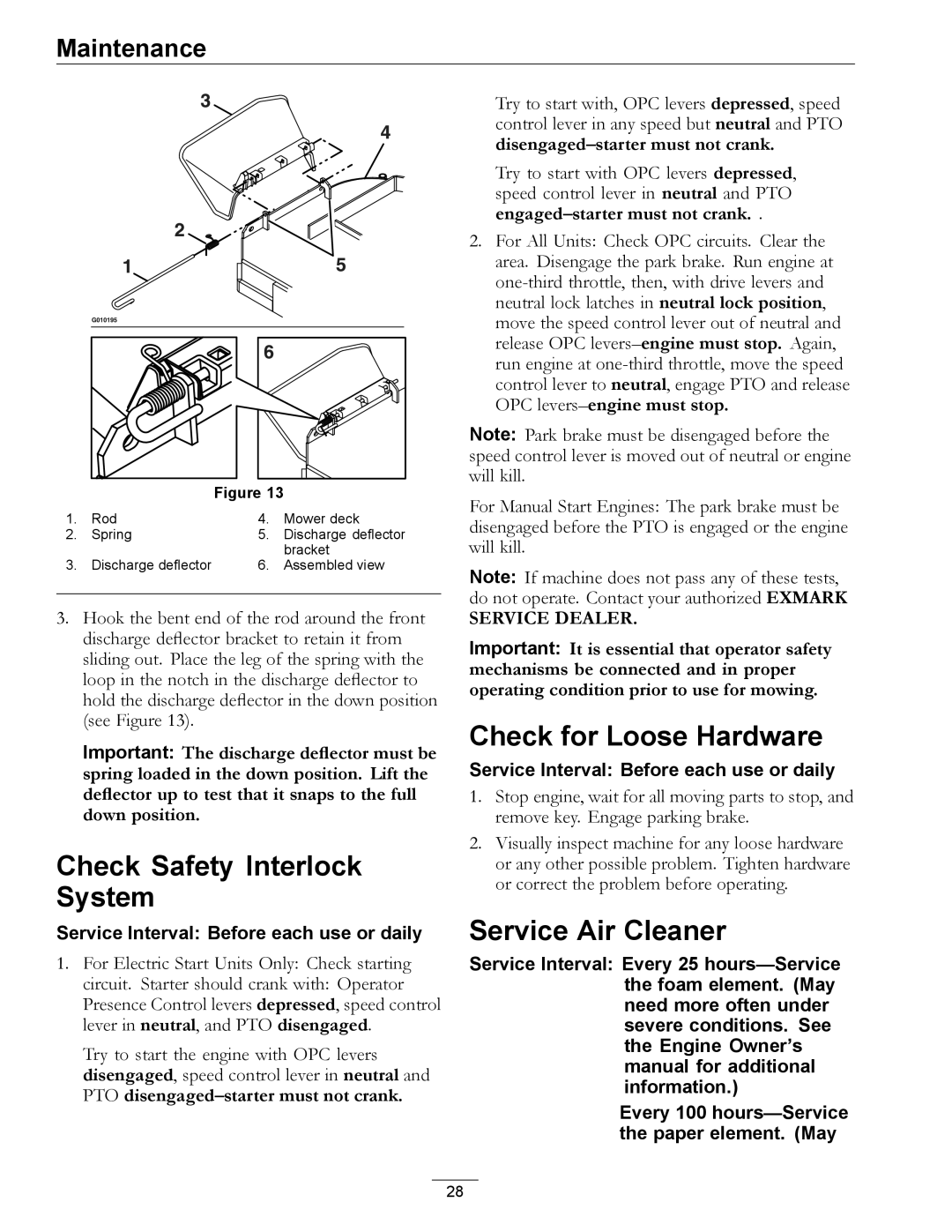

2.For a heavier drive setting, relocate the spring anchor link as shown in Figure 13. The spring anchor links are located under the engine deck on the left and right hand sides.

Note: In “medium” or “heavy duty” positions, the drive lever forces at the upper handle will also be increased.

PTO Safety Switch

Mounted to a tab on the inside left side of the fuel tank support.

1.Stop engine and wait for all moving parts to stop. Engage parking brake. Remove ignition key or spark plug wire(s).

2.With PTO disengaged and the bellcrank touching the rear of the slot in the engine deck, adjust the PTO safety switch (if needed) until the bellcrank arm is 5/16 inch (7.9 mm) from the switch body.

3.Be sure the bellcrank Does Not touch the switch body or damage to the switch could occur.

4.Retighten PTO switch mounting hardware.

Figure 20

1. | Heavy duty | 3. | Standard |

2. | Medium duty | 4. | Retaining bolt |

|

|

|

|

36