Product Overview

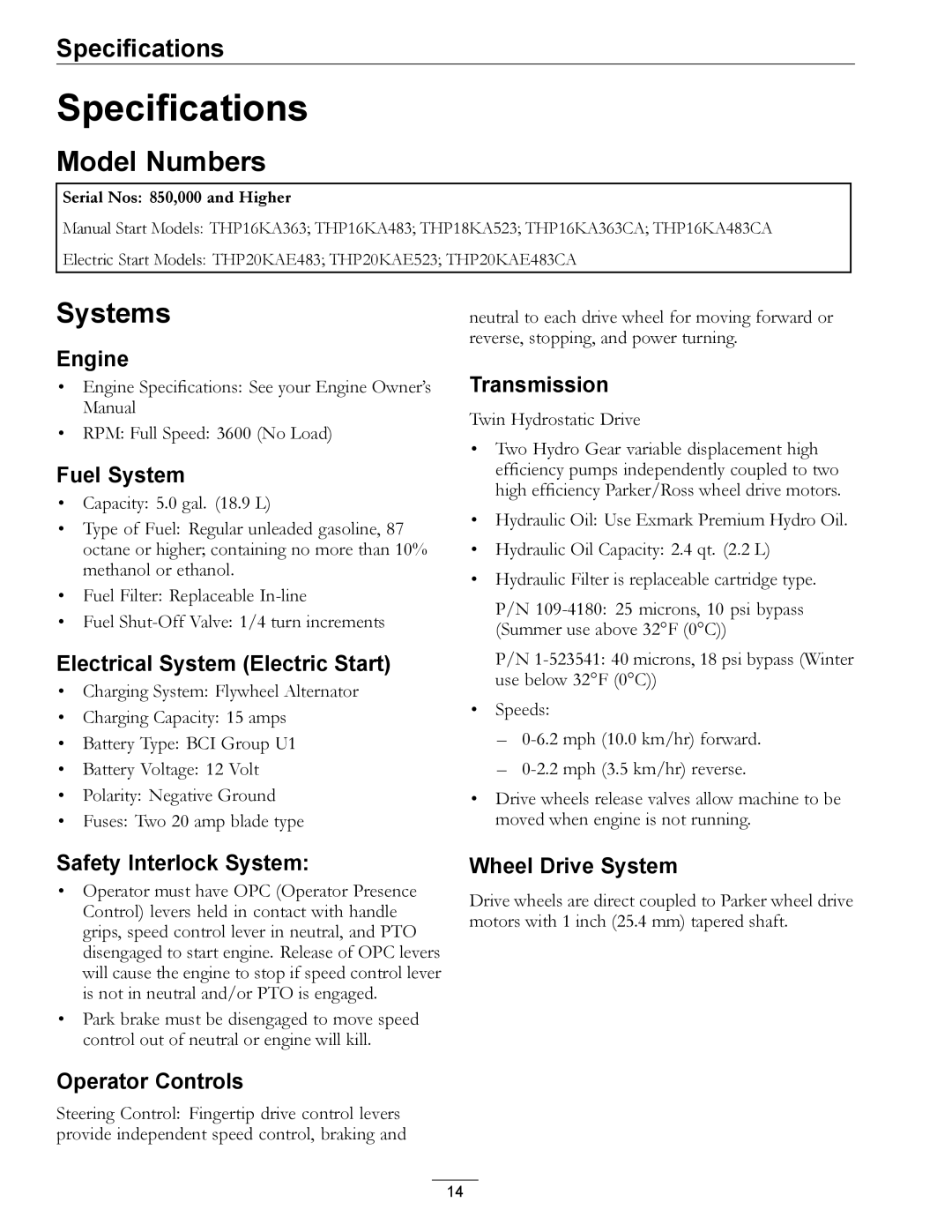

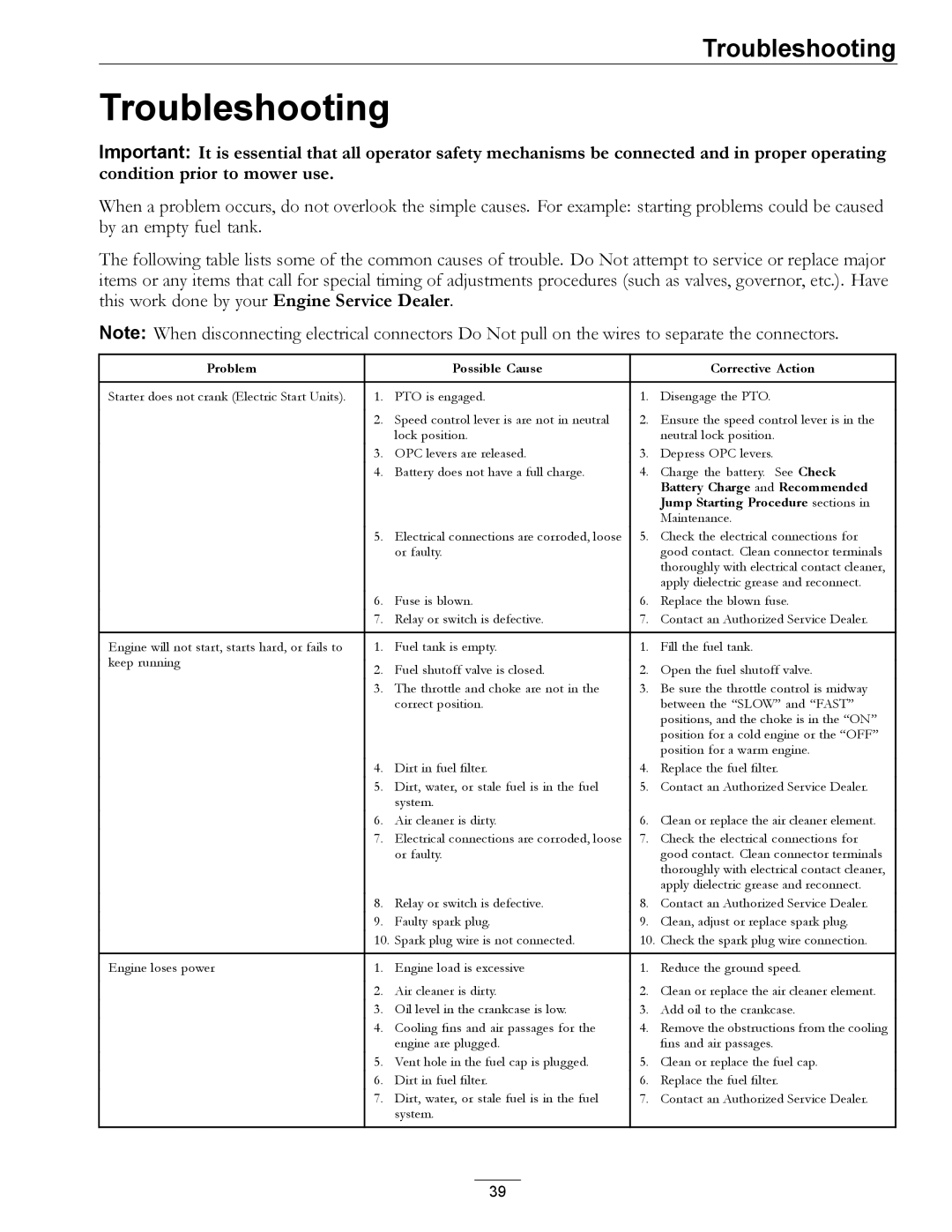

Torque Requirements | Product Overview | ||||

Bolt Location | Torque |

|

|

|

|

Cutter Housing Spindle |

|

|

|

| |

Nut |

|

|

|

| |

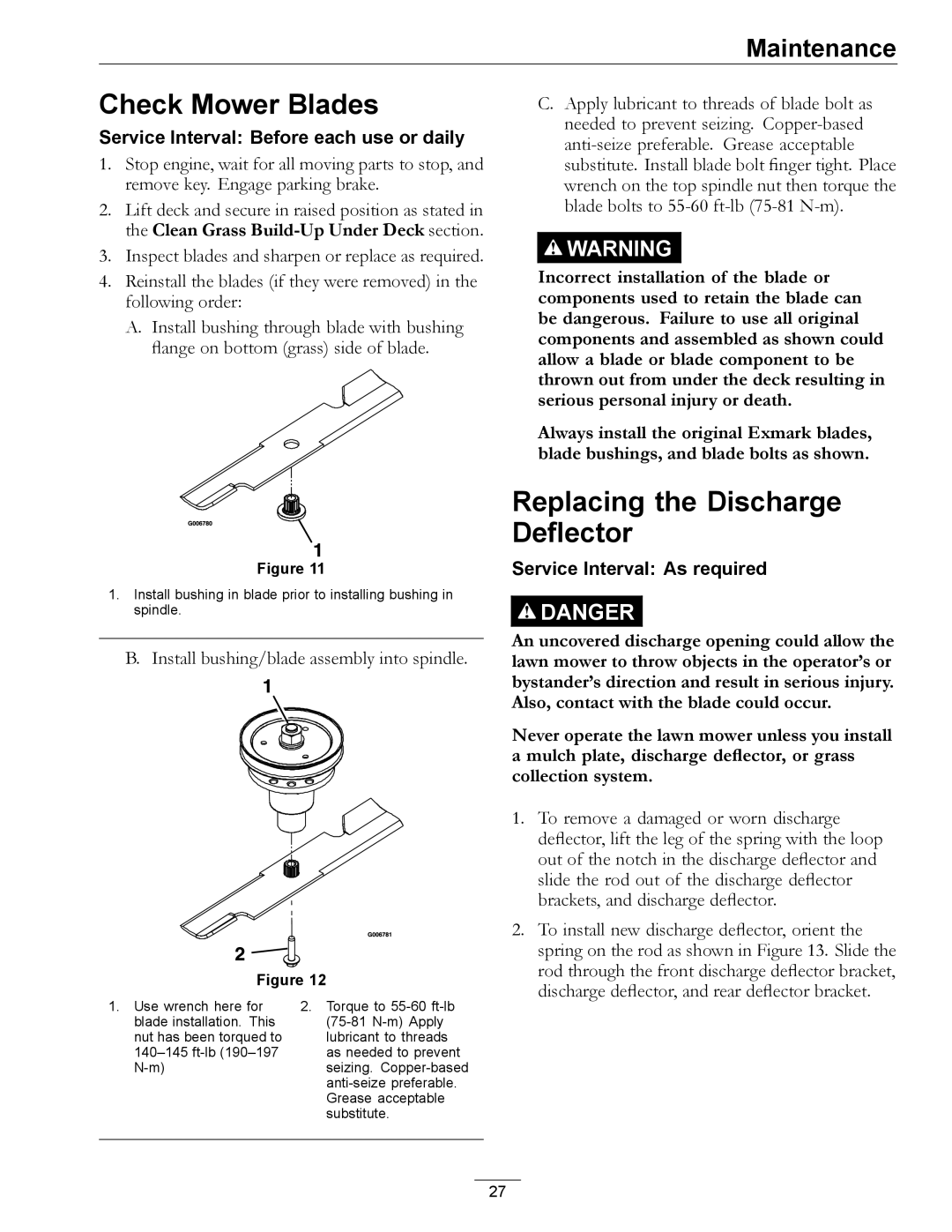

Blade Mounting Bolt |

|

|

|

| |

(lubricate with |

|

|

|

|

|

Engine Deck/Mower |

|

|

|

| |

Deck Support Mount |

|

|

|

|

|

Bolts |

|

|

|

|

|

|

|

|

| ||

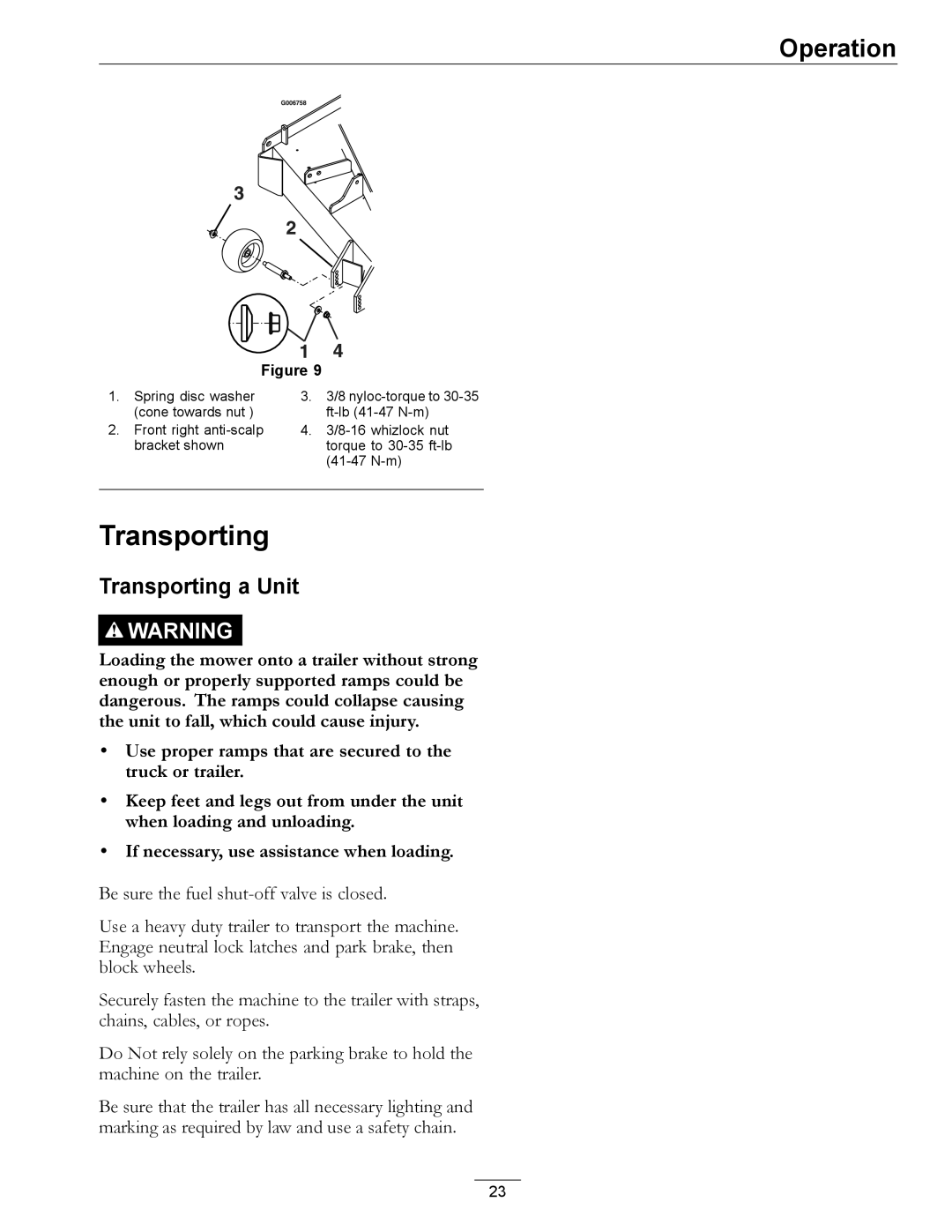

Nut See Figure 9 |

|

|

|

|

|

|

|

|

| ||

Nut See Figure 9 |

|

|

|

|

|

Engine Mounting Bolts |

|

|

|

| |

Wheel Lug Nuts |

|

|

|

| |

Wheel Hub Slotted Nuts | minimum 100 |

|

|

|

|

| (136 |

|

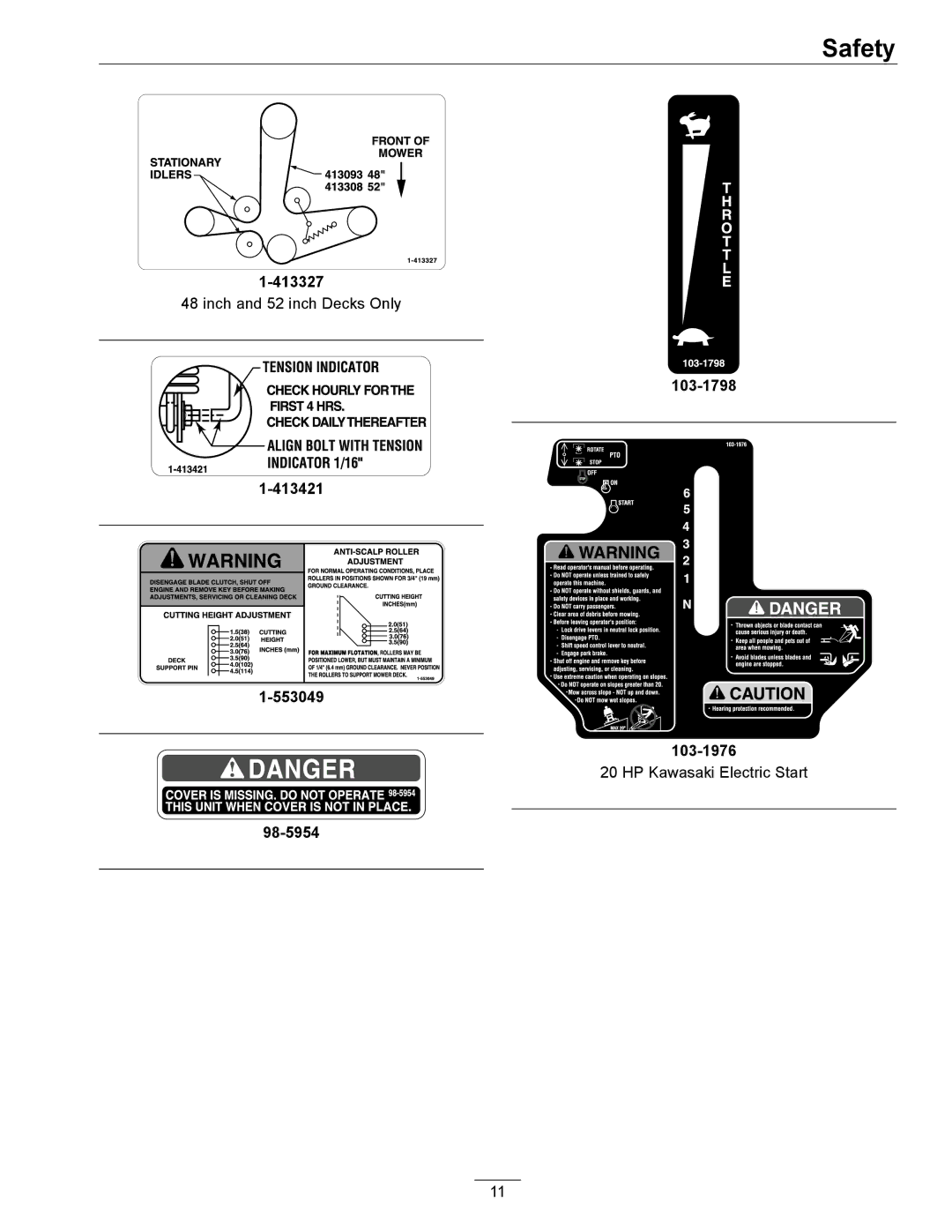

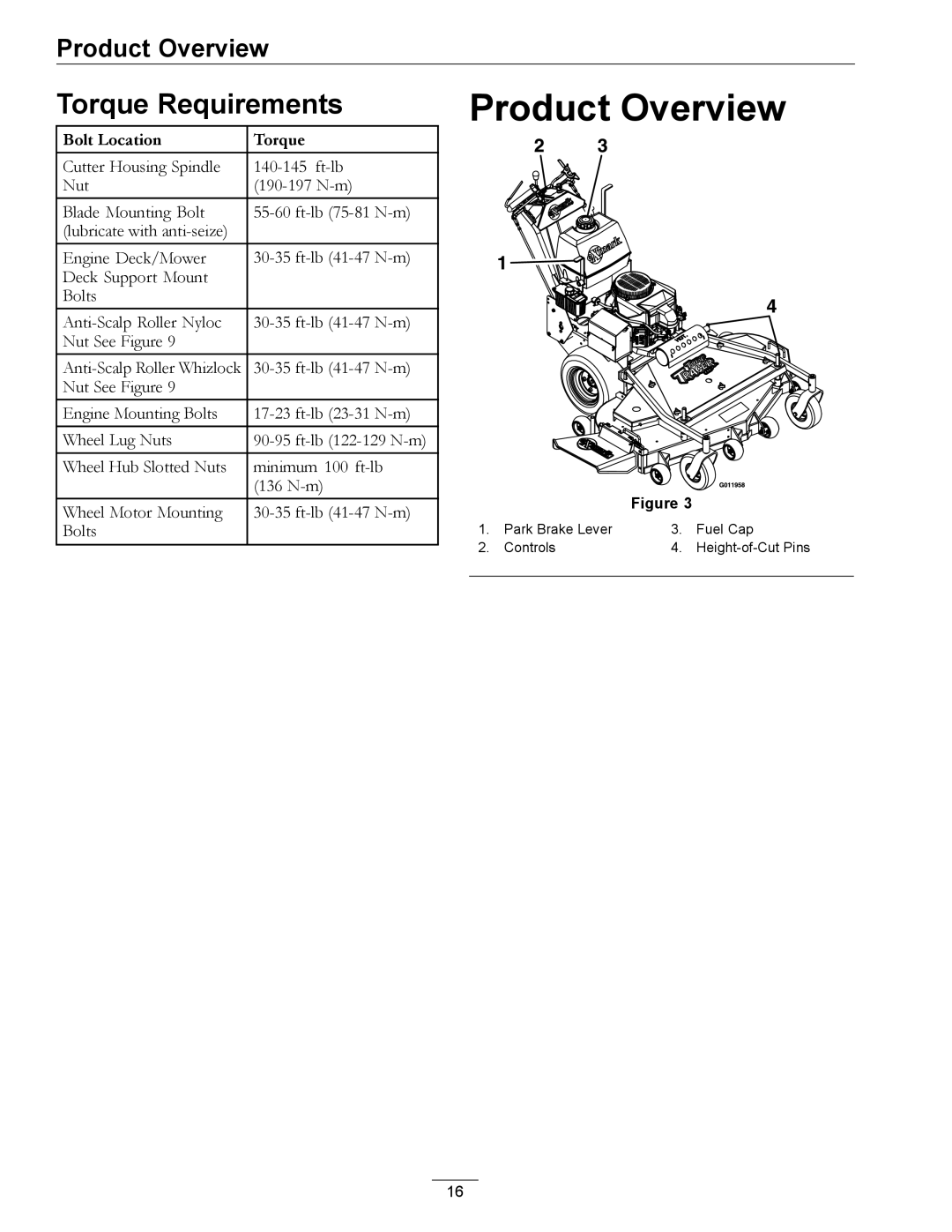

| Figure 3 |

|

Wheel Motor Mounting |

|

|

| ||

|

|

|

| ||

Bolts |

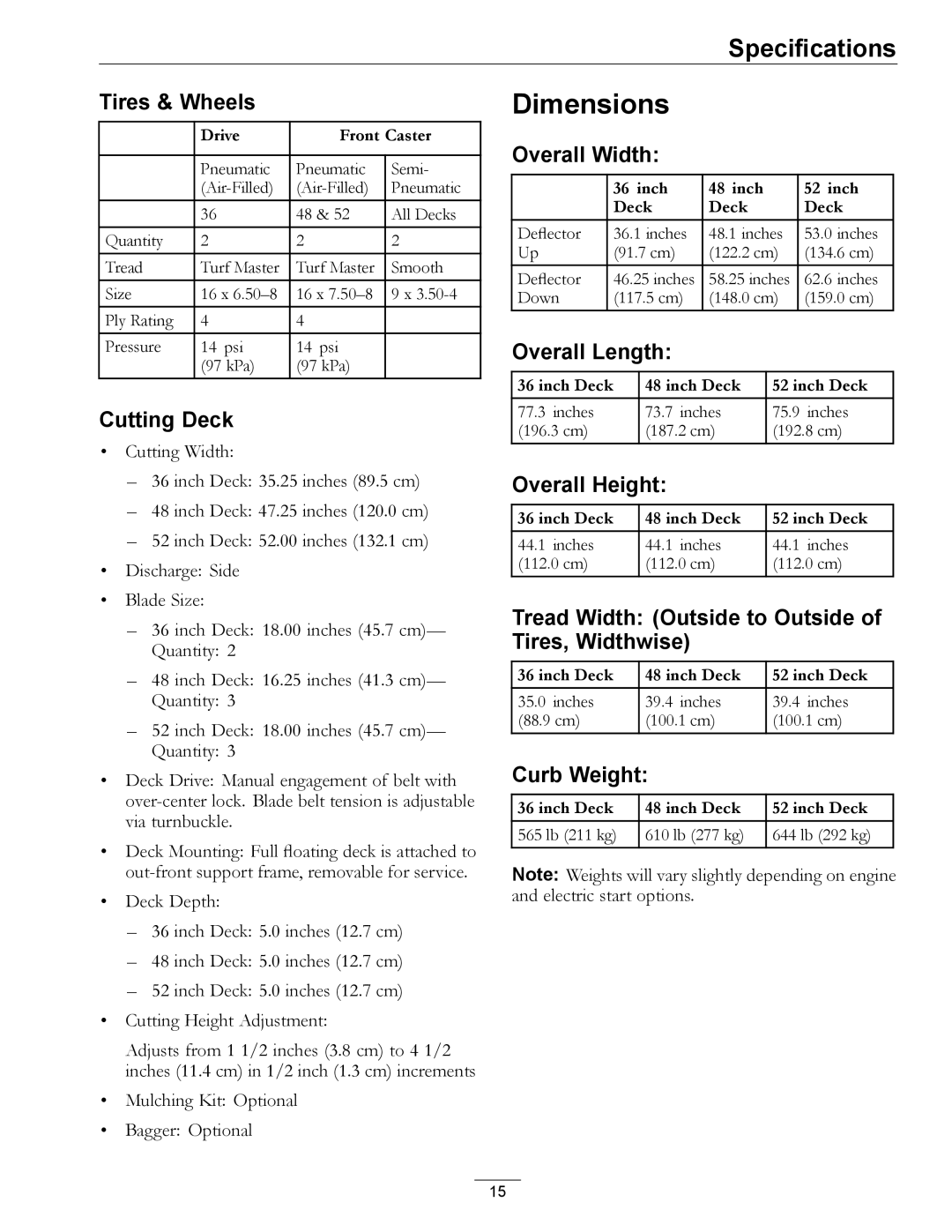

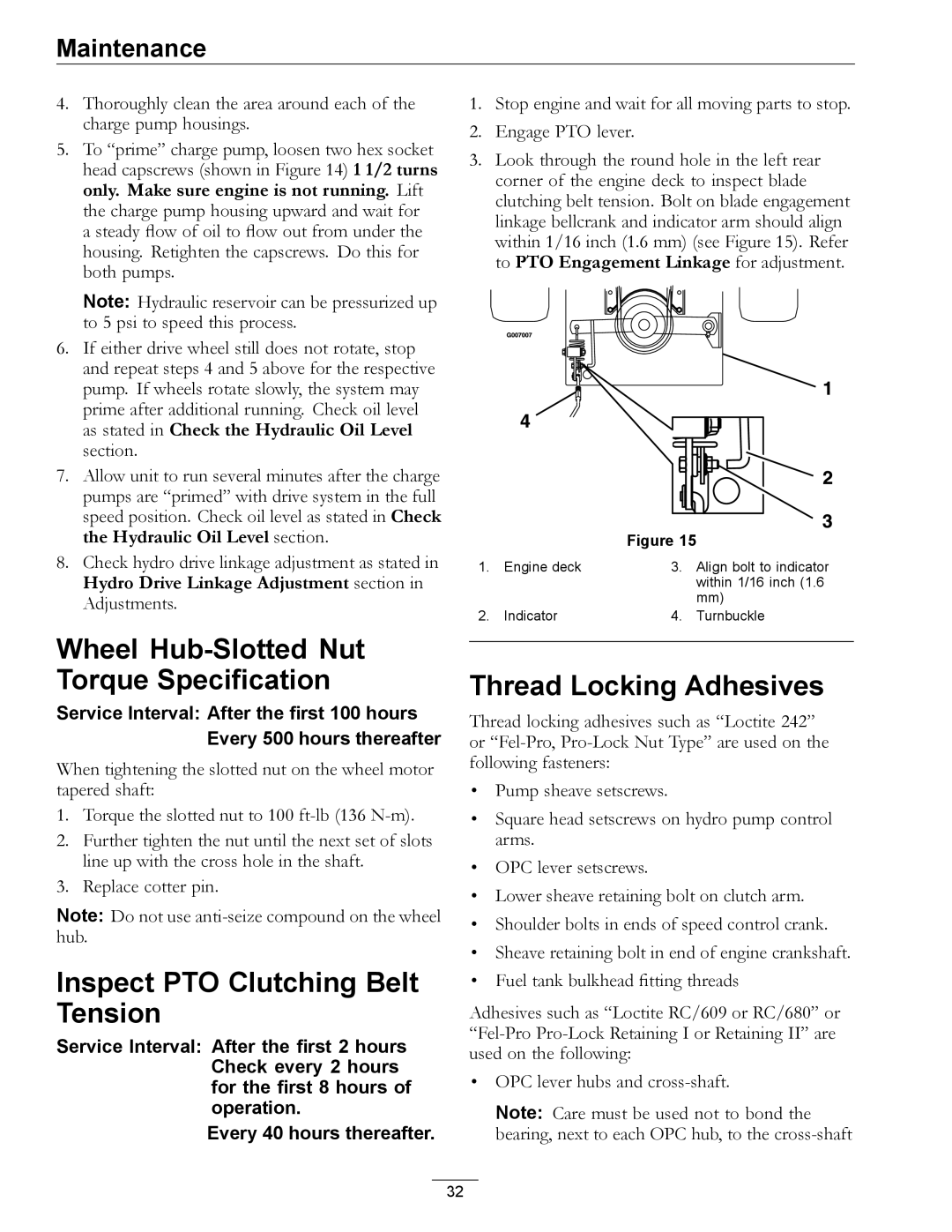

| 1. | Park Brake Lever | 3. | Fuel Cap |

|

| 2. | Controls | 4. | |

16