40CHAPTER 6: TROUBLESHOOTING THE SYSTEM

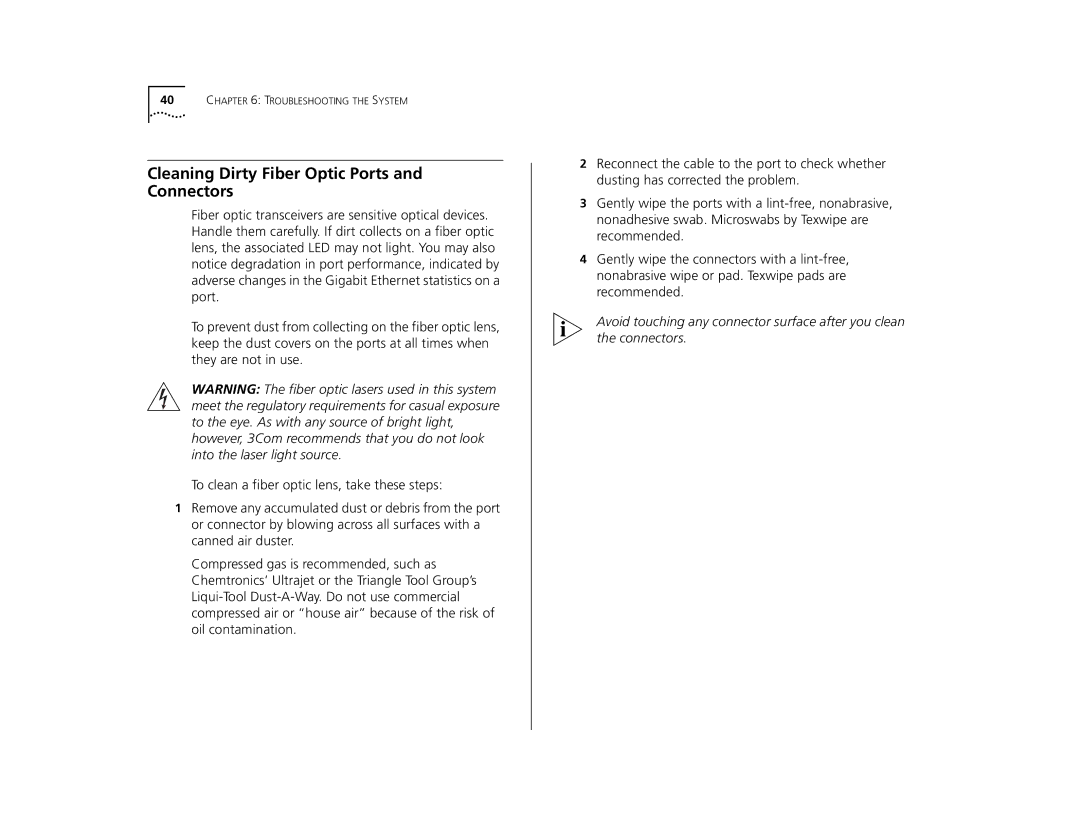

Cleaning Dirty Fiber Optic Ports and Connectors

Fiber optic transceivers are sensitive optical devices. Handle them carefully. If dirt collects on a fiber optic lens, the associated LED may not light. You may also notice degradation in port performance, indicated by adverse changes in the Gigabit Ethernet statistics on a port.

To prevent dust from collecting on the fiber optic lens, keep the dust covers on the ports at all times when they are not in use.

WARNING: The fiber optic lasers used in this system meet the regulatory requirements for casual exposure to the eye. As with any source of bright light, however, 3Com recommends that you do not look into the laser light source.

To clean a fiber optic lens, take these steps:

1Remove any accumulated dust or debris from the port or connector by blowing across all surfaces with a canned air duster.

Compressed gas is recommended, such as Chemtronics’ Ultrajet or the Triangle Tool Group’s

2Reconnect the cable to the port to check whether dusting has corrected the problem.

3Gently wipe the ports with a

4Gently wipe the connectors with a

Avoid touching any connector surface after you clean the connectors.