Installation and Set-Up (Continued)

11.Box size capacity (height) – at its factory setting, the case sealer handles box sizes up to 620 mm

12.Drive Belt Height – drive belt assemblies can be raised 50 mm [2 inches] to provide better conveying of tall boxes. Refer to "Special

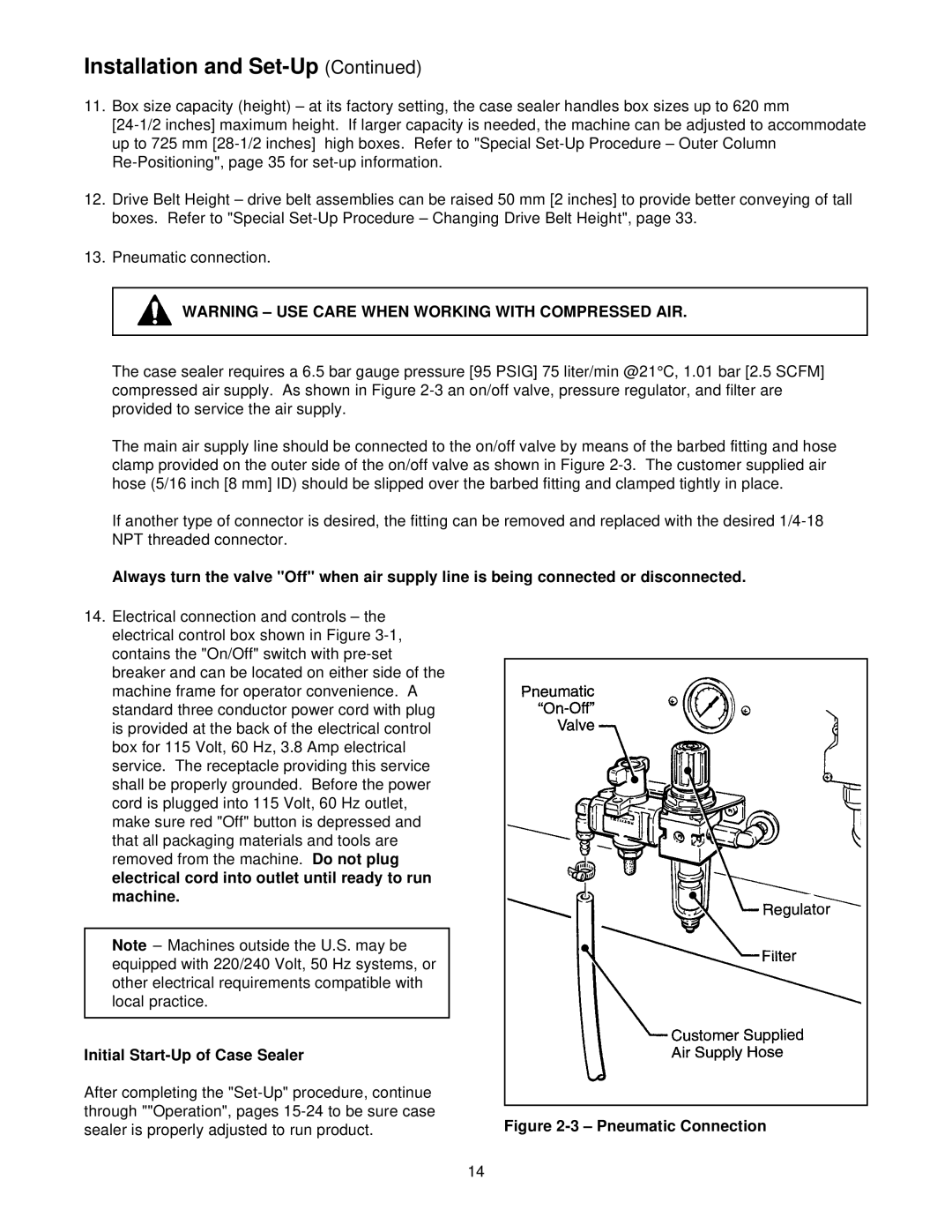

13.Pneumatic connection.

WARNING – USE CARE WHEN WORKING WITH COMPRESSED AIR.

The case sealer requires a 6.5 bar gauge pressure [95 PSIG] 75 liter/min @21°C, 1.01 bar [2.5 SCFM] compressed air supply. As shown in Figure

The main air supply line should be connected to the on/off valve by means of the barbed fitting and hose clamp provided on the outer side of the on/off valve as shown in Figure

If another type of connector is desired, the fitting can be removed and replaced with the desired

Always turn the valve "Off" when air supply line is being connected or disconnected.

14.Electrical connection and controls – the electrical control box shown in Figure

Note – Machines outside the U.S. may be equipped with 220/240 Volt, 50 Hz systems, or other electrical requirements compatible with local practice.

Initial |

|

After completing the |

|

through ""Operation", pages | Figure |

sealer is properly adjusted to run product. |

14