Agilent 85225F

Manual Part Number

Safety and Regulatory Information

Understood and met

Table a Safety Symbols

SymbolsDefinition

Table B Instrument Markings

Marking Definition

Do not Operate in AN Explosive ATMOSPHERE. Do not operate

Must not remove instrument covers. Component replacement

Do not Remove the Instrument COVER. Operating personnel

Mains power

Fuses and breakers

For protection against fire hazard, use only fuses with

Compliance with German Noise Requirements

Acoustic Noise Emission/Geraeuschemission

This Guide

Introducing the Agilent 85225F Performance Modeling System

CV Subsystem Functional Verification Tests

Interface

Interface Examples in Body Text

Tables

Click Enter

Contents

Electrical Requirements

To prepare the installation site Environmental Requirements

To unpack the shipment crate containing the rack cabinet

101

If you encounter a problem

Bias Network Schematic

CV, RF, and DC Measurement System Configuration

Performance Modeling System Configuration Overview

RF and DC Measurement System Configuration

Performance Characteristics and Specifications

Performance Modeling System Configuration Overview

RF and DC Measurement System Configuration

System Block Diagram

RF Subsystem

DC Subsystem

Bias Networks

Component Integration

System Components

Front Panel System Connections, with Agilent 4156C

Number Type Instrument Labeled

Front Panel Connections with Agilent 4156C

16493L Triaxial Triax BNC E5260A/70B

16494A Triaxial cable Triax BNC E5260A/70B

Option Gndu cable

Front Panel Wiring Diagram with Agilent E5260A or E5270B

10833C Gpib cable

Rear Panel System Connections with Agilent 4156C

10833D Gpib cable

Controller

Rear Panel Wiring Diagram with Agilent 4156C

Rear Panel System Connections with Agilent E5260A or E5270B

10833A Gpib cable

Rear Panel Wiring with Agilent E5260A or E5270B

Introducing the Agilent 85225F Performance Modeling System

CV, RF, and DC Measurement System Configuration

CV Subsystem

System Components

Front Panel System Connections

Front Panel Wiring Diagram

Rear Panel System Connections

Rear Panel Wiring Diagram

DC/RF Cabling Diagram DC and RF Configuration

DC/RF Cabling Diagram Parametric Configuration

Low Leakage Switch Mainframe

Installation and User’s Guide

Introducing the Agilent 85225F Performance Modeling System

Noise, CV, RF, and DC Measurement System Configuration

1/f Noise Subsystem

F Noise Measurement Block Diagram

Customer supplied, not included with system

System Components

Option Gndu cable 85133F Flexible test E8364B

16494A Triaxial cable Triax BNC 41501B

16493L Triaxial Triax BNC 41501B

Test cable Or probe Station 8120-1839 Coaxial cable

Front Panel Wiring Diagram

16493L Gndu cable Triax BNC 41501B

Option 10833A Gpib cable

Rear Panel Wiring Diagram

DC/RF Cabling Diagram DC and RF Configuration

DC/RF Cabling Diagram Parametric Configuration

Gpib Addresses

Instrument Control Interface

Component Gpib Address

LAN/GPIB Gateway

Rear Panel Wiring Diagram for LAN/GPIB Gateway

Unix Workstation Requirements

System Controller

Personal Computer Requirements

Parameter Requirement

Rack Cabinet

Supplemental System Characteristics

Performance Characteristics and Specifications

Performance Modeling System Performance Specifications

Characteristic Value

Bias Network Characteristics

RF Subsystem Performance Specifications

DC Subsystem Specifications

Station or test fixture characteristics

To switch on power to the system

To ensure your safety while using the system

Precautions for Avoiding Electrostatic Discharge

Starting on page 91

Pollution Degree 2 per IEC 61010-1 and 664 respectively

To prepare the installation site

To prepare the installation site

Environmental Requirements

To receive the system

To receive the system

Step Action

To unpack the shipment crate containing the rack cabinet

To unpack the shipment crate containing the rack cabinet

Folded position

Hinged slat

Step Action Unload the system

Wood screws through the ramp

Into the ramp ledge

To verify the shipment

To verify the shipment

Replaceable Parts

Part or Model Number Description

Option AY6 Four-input channel configuration

Dynamic signal analyzer

Option AY2 Two-input channel configuration

Option Triaxial cable, 1.5 meter

User’s Guide

Replaceable Parts

Replaceable Parts

Prepare to install the work

To install the work surface

To install the work surface

Lock feet prevent the cabinet from

To install the work surface

To ensure your safety while using the system

Ground

Measurements Measurement is in progress

Following section Precautions for

Floating-ground Disconnected and a floating-ground

Fuses with incorrect

To connect an external ground to the circuit common

Precautions for Performing Floating-Ground Measurements

To perform floating-ground measurements

Circuit common is not connected through the bias networks

Precautions for Avoiding Electrostatic Discharge

To take precautions against electrostatic discharge

To connect the bias networks

To connect the bias networks

Agilent 4156C Systems

For Agilent 4156C systems, refer to the following figure

Bias network Through the upper feedthrough panel

Connector to the port

Bias network open

Connect the bias networks to the device under test

HRSMU3 Force connector to the port 2 bias network

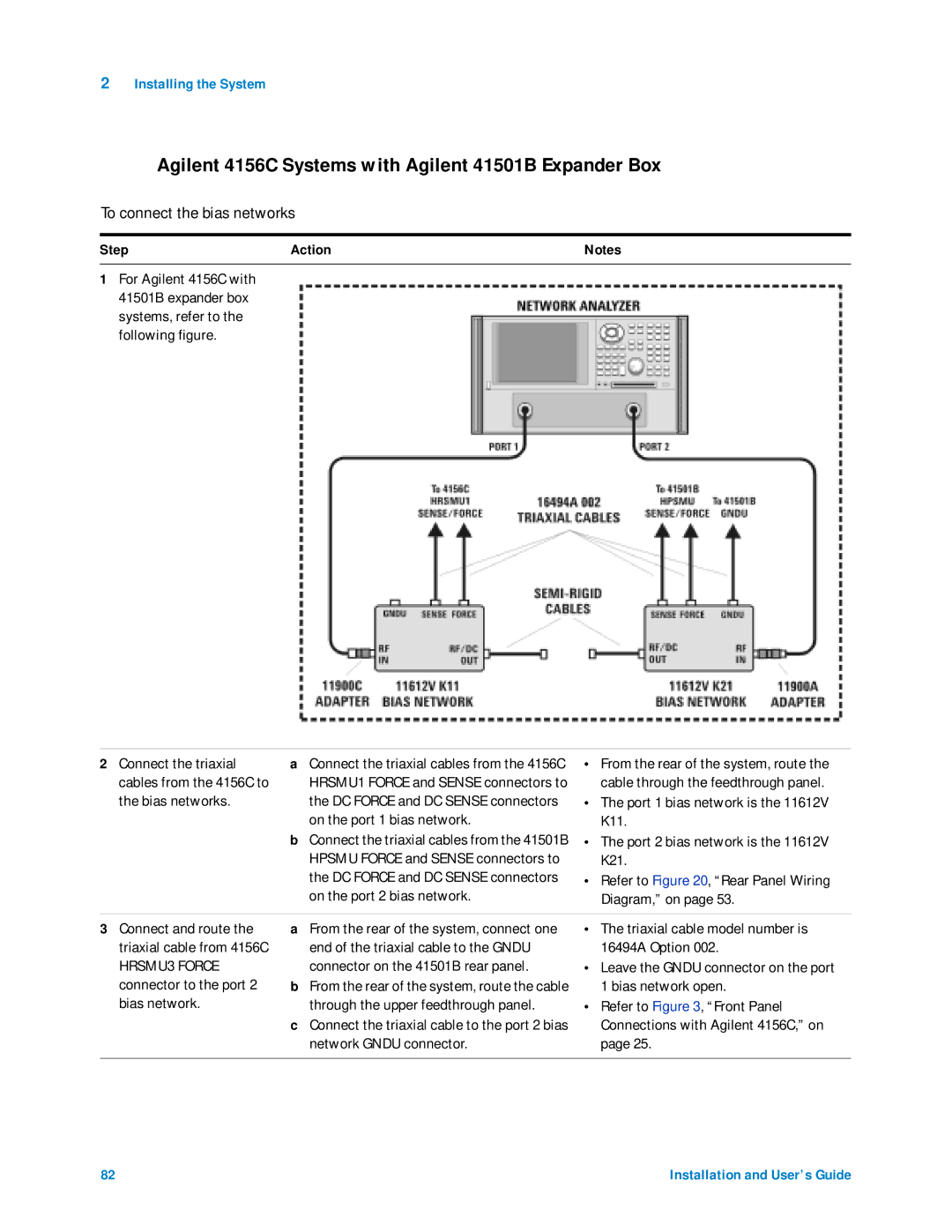

Agilent 4156C Systems with Agilent 41501B Expander Box

2.4 mm female-to-male adapter

Port cable to the 2.4 mm female-to-male

Agilent E5260A/70B Systems

Connect the triaxial Connect the triaxial cable from

Cables from E5260A/70B medium power SMU to E5281A

High power SMU is the Agilent

Port 2 bias network is

Connect the bias

Networks to the device

To switch on power to the system

Switch on the computer line power

Vector network analyzer line power

Line power

To set the address to 19 and press Enter

Choose Tools Hardware Setup... .†

To configure the LAN/GPIB gateway

Add Interface

Installing the System

Understanding the System Functional Verification Test

To choose a verification process

Performing the System Functional Verification Test

To choose a system verification process

Performance specifications

To choose a verification process

Situation Action

Verifying System Functionality

Understanding the System Functional Verification Test

Required Tools

Performing the System Functional Verification Test

To perform the system functional verification test

PC version

Examples/modelfiles

Choose File Examples

Modelfiles/misc

Select Calibration Wizard

Macros tab

Select Calibrate

If you encounter a problem

102

Servicing the System

To troubleshoot the system

Remove the four screws 2 screws

To remove or replace a system component

To remove a system component

Frame nuts

To order replacement parts

To receive additional assistance

Contacting Agilent Technologies

To package the system for transport

To package the system for transport

Installation and User’s Guide 109

110

Performing a Coaxial System Measurement Calibration

To enhance measurement accuracy

Understanding System Measurement Calibration

Periodic System Component Calibration

To enhance measurement accuracy

On the network analyzer

Always perform a Prior to making device measurements

Measurement calibration

For more information

Understanding System Measurement Calibration

To perform the system measurement calibration

Connector types Connectors dialog box, select

Performing a Coaxial System Measurement Calibration

Networks

Networks RF/DC OUTPUT. connectors Click Measure

Adapters using Click Measure Standard open, short

Load, and through Short to the Port 1 bias network RF/DC

Periodic System Component Calibration

118

Performing the DC Subsystem Functional Verification Test

Understanding the DC Subsystem Functional Verification Test

Understanding the DC Subsystem Functional Verification Test

For Agilent E5260A/70B DC subsystems

Performing the DC Subsystem Functional Verification Test

122

Understanding the RF Subsystem Functional Verification Test

Understanding the RF Subsystem Functional Verification Test

To perform the RF subsystem functional verification test

Operator’s Check Click Configure

Performing the RF Subsystem Functional Verification Test

Automatic

126

Installation and User’s Guide 127

128

CV Subsystem Functional Verification

Understanding the CV Subsystem Functional Verification Test

Performing the CV Subsystem Functional Verification Test

Manual

132

Noise Subsystem Functional

F Noise Subsystem Functional Verification Test

If the instrument self test fails, consult Chapter

136

Features

Understanding the Bias Networks

Features

11612V Option K11/K21 Bias Network Characteristics

Characteristics

Parameter 11612V Option K11 11612V Option K21

Operation

Dynamic Range

Network Analyzer System Performance

Measurement Uncertainty

Network Analyzer System Performance

Maximum Output Power

Dynamic Range

Measurement Port Characteristics

Measurement Uncertainty

Transmission Measurements

Index

Procedure

Index

Procedure, manual

Description

148